3D Hubs intern Jack Davies improved his daily commute by creating a 3D printed electric skateboard with HP Jet Fusion technology.

An intern at 3D printing startup 3D Hubs in Amsterdam has just created a 3D printed electronic skateboard that is comparable to existing commercial alternatives.

Jack Davies, a student at Nottingham Trent University in the UK, sought a better way to get around the famous Dutch capital when he began his internship at 3D Hubs. Within less than a week, Davies created the “Fusion E-Board” for under €600, tapping into his knowledge of electronics and design.

According to Davies, he based his design on off-the-shelf parts for the board’s main components and used the Autodesk Fusion 360 software to model the separate elements of the skateboard.

“I calculated the desired top speed and torque requirements which then enabled me to select the motors and battery for the board. The gearing ratio was also calculated and the pulley sizes were selected, along with the drive belt length. This enabled me to work out the correct size of the motor mounts which ensured a well-tensioned belt. The next stage was to design the battery and speed controller (ESC) enclosures,” he explains.

HP Jet Fusion 3D Printing Helps Skateboard Project Get Rolling

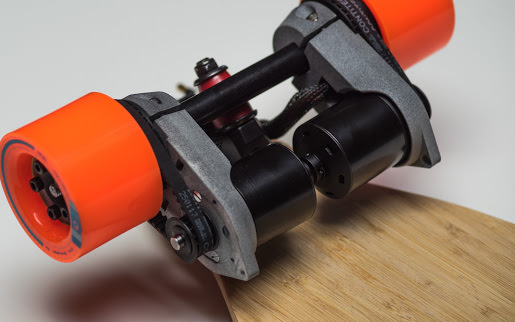

The custom enclosure parts of the board is made using industrial printing technologies courtesy of 3D Hubs. Davies used the HP Jet Fusion 3D 4200 Printer for the project. This industrial machine is capable of modeling more complex shapes whilst retaining strength of the parts. The project incorporated HP 3D HR PA 12 nylon parts, effectively replacing traditional aluminum components that are more expensive to create.

The HP nylon was also used to create the protective ribs, drivetrain and motor mounts of the skateboard. The nylon offers superior resistance to heat and is able to withstand strong force and stress.

The board itself is comparable to commercially available options starting at €1500. However, the custom printed parts on the Fusion E-Board cost just €250 (and €350 for the standard parts).

Davies explains that compatibility of the 3D printed components was the most challenging part of the project due to budget constraints. If something were to go wrong, the parts are not simply replaceable. Therefore, any mechanical conflicts required elimination and precise testing by using low-cost FDM prototypes.

Davies’ skateboard is yet another example of how 3D printing makes it possible to find solutions to challenging problems.

The design files for the “Fusion E-Board” are now publicly available to download from 3D Hubs. Davies hopes that they may inspire other students and designers to create similar boards.

Source: 3D Hubs

License: The text of "3D Hubs Intern Creates 3D Printed Electric Skateboard to Ease His Daily Commute" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.