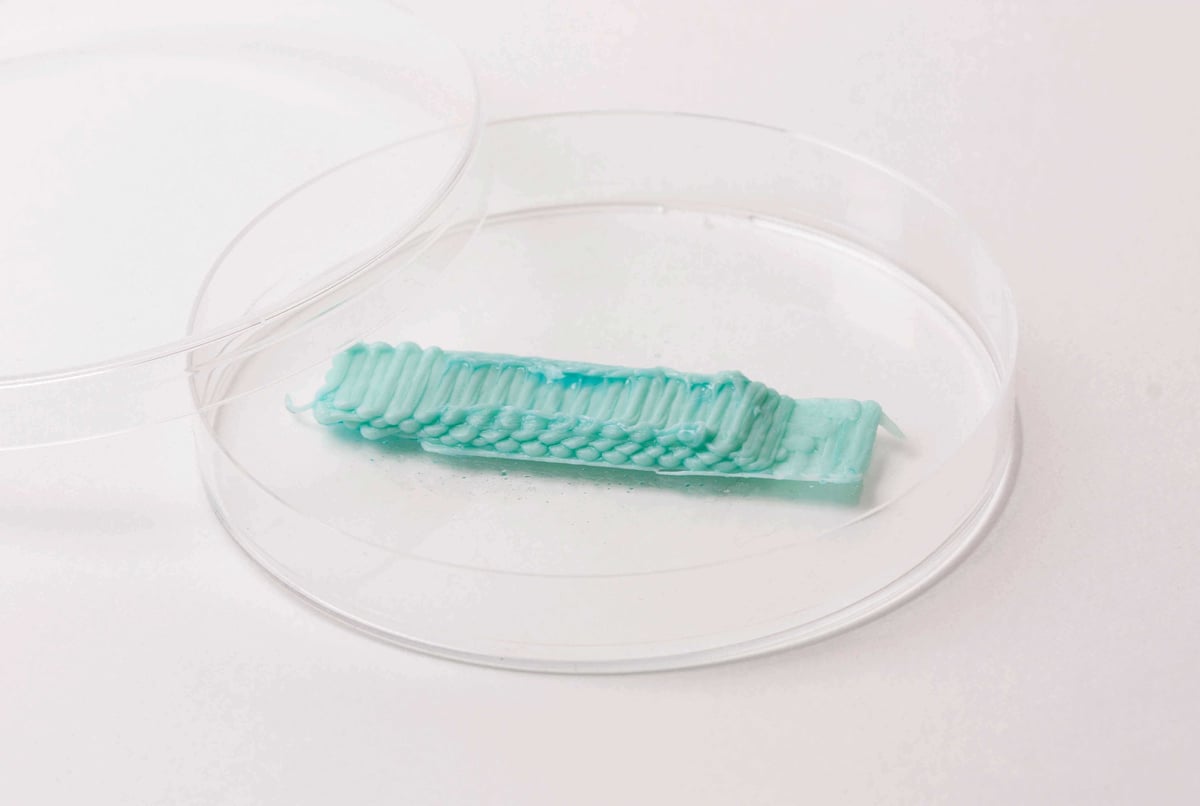

3D printing of food is one of the latest trends, having seen intensive development activity during the past few years, with exciting new milestones being reached with every new advancement. We’ve seen printers make objects out of sugar, chocolate, bread and even meat for custom made hamburgers. Imagination is the limit, and no one had yet imagined 3D printing of an actual chewing gum. That is until the gumlab.uk team did it, successfully overcoming quite a few material related issues.

Getting Sticky With It

First of all, hot gum is sticky. Stick in the 3D printing world means frequent nozzle clogging, endless imperfections because of the very high precision required for feeding of the gum material, sticky heating bed and sticky base plate. All these problems can be left behind only if a materials expert is involved in the development of the gum printer, and that is exactly what gumlab did by collaborating with Ph.D. Maria Nelson. She works in the Materials Department at the London Imperial College. Along with artist Chia-Ling Lin, have created one of the most “common” but very creative 3D printing applications so far.

Through their system, anyone could now create his or her custom made chewing gum by mixing various special materials with different properties (taste, color, smell, texture, shape). All of those materials contain natural tree-resins that are safe for human consumption and fully digestible in case of ingestion. Now some of you may ask: “who cares about chewing gum?” However humans historical data, as reported by the gumlab.uk team, tells us that humans have been enjoying chewing gum for over 9000 years!

Keep On Chewing

“Mastic” was loved by people since the ancient times for its teeth cleaning abilities, contribution to healthy gums, aromatic properties and aid in the digestion process. It is indicative that the natural “Chios” mastic was once worth its weight in gold. Nowadays, it is commonly used as a mind and thought activity enhancer so many artists, athletes and writers chew a piece of gum during their work for a better mental performance. The thing is, though, that nowadays natural tree resin is substituted by petroleum-based products that have similar mechanical properties but are nowhere close to the health benefits of the original mastic.

Thinking of the possibilities of 3D printed chewing gums is quite reassuring. People can use them as custom themed promotional tools in events, or just create their gum of choice that can’t be found in the market. Gums without sugar or even taste at all, or gums that look like 3D fractals ready to tickle your taste buds? Mellon smell with Strawberry taste in the shape of a heart? (Almost) anything is possible with gumlab, and when the printing resolution gets better, and the materials collection grows larger, the scope of possibilities will expand with geometric progression. However, the shape of the bubble will likely remain the same.

License: The text of "Chew on this: 3D printed bubble gum" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.