Researchers from Piedmont Heart Institute and the Georgia Institute of Technology are using 3D printed heart valves to improve the success rate of aortic valve replacements.

3D printing is regularly used to improve pre-surgical planning. The technology allows surgeons to create patient-specific 3D models, aiding them with surgery success rates.

One example is 3D printed heart valves, which closely mimic the qualities of organic valves. They come as the result of collaborative efforts between Piedmont Heart Institute and the Georgia Institute of Technology.

The two research teams believe that, through 3D printing, physicians can more easily select devices, assess risk, and optimize deployment techniques. In turn, this would benefit the tens of thousands of patients diagnosed with heart valve disease every year.

The artificial heart valves aid pre-surgical planning for a treatment called transcatheter aortic valve replacement (TAVR). Physicians often choose this procedure for patients at risk of complications from open-heart surgery.

Meanwhile, TAVR comes with its own own problems and risks. First on the list is paravalvular leakage (PVL), which occurs when a new valve doesn’t fit properly. With 3D printing, researchers hope to reduce the chance of PVL.

Often TAVR comes down to choosing the right prosthetic. However, even a surgeon’s expert knowledge can be augmented with 3D printing, which can indicate in vitro if a selected valve truly is the best fit.

Ensuring TAVR has a High Success Rate with 3D Printing

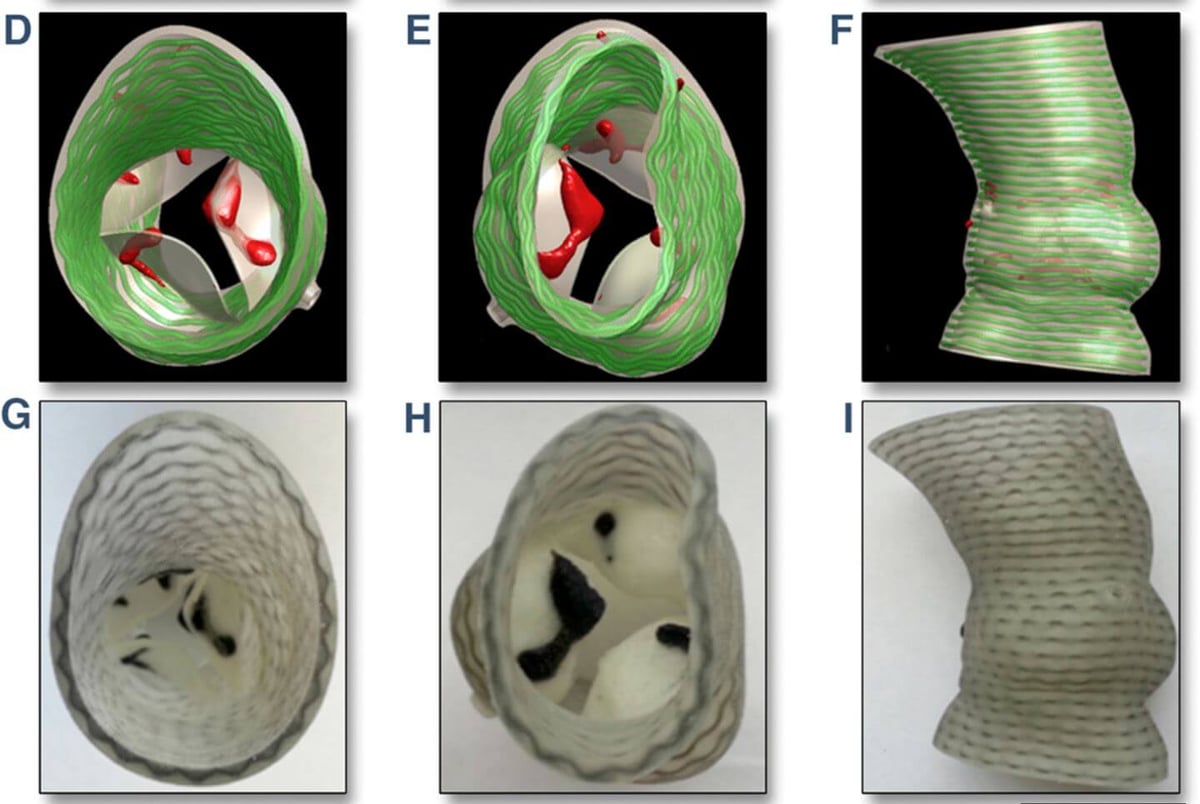

To create patient-specific heart valves, the research teams used PolyJet 3D printing technology, from Stratasys. In addition, they developed a pre-procedural planning platform to help predict the risk of PVL.

Testing the 3D prints was accomplished by analyzing data collected from eighteen models. The results are promising, and indicate a real potential for predicting location and severity of leakage.

Zhen Qian, chief of CV imaging research at Piedmont Heart Institute, comments:

“Eventually, once a patient has a CT scan, we could create a model, try different kinds of valves in the 3D model, and identify which one might work best. We could even predict that a patient would probably have moderate PVL and utilize balloon dilatation to solve it.”

For now, surgeons still face a challenge in that 3D printing is an expensive option. Indeed, customized models require a lot of time for printing and post-processing. Nevertheless, Qian is hopeful for the future application of the technology and believes the current progress to be a positive start.

Want to find out more? Read the paper: Quantitative Prediction of Paravalvular Leak in Transcatheter Aortic Valve Replacement Based on Tissue-Mimicking 3D Printing.

Source: Stratasys

License: The text of "3D Printed Heart Valves Improve Surgery Success Rates" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.