Throughout history, there are many examples of people that took existing tools one step further with their creativity and passion for unconventional ways of development. South African engineer and inventor Hans Fouche is one of those examples. He has devoted himself to adapting existing 3D printing technologies to large-scale production machines for home usage. One of his most publicized recent creations, a fully 3D printed lawnmower body, is just one in a long line of incredible, large size, functional everyday objects 3D printed by Fouche.

The primary limitations that most commercial production-grade printers face are the very high cost of acquisition, high cost and limitations of materials and relatively small dimensions of their print bed. This means that any large 3D printed object generally requires time and devotion both for the design and the assembly process.

A Modern Day 3D Printing Hero

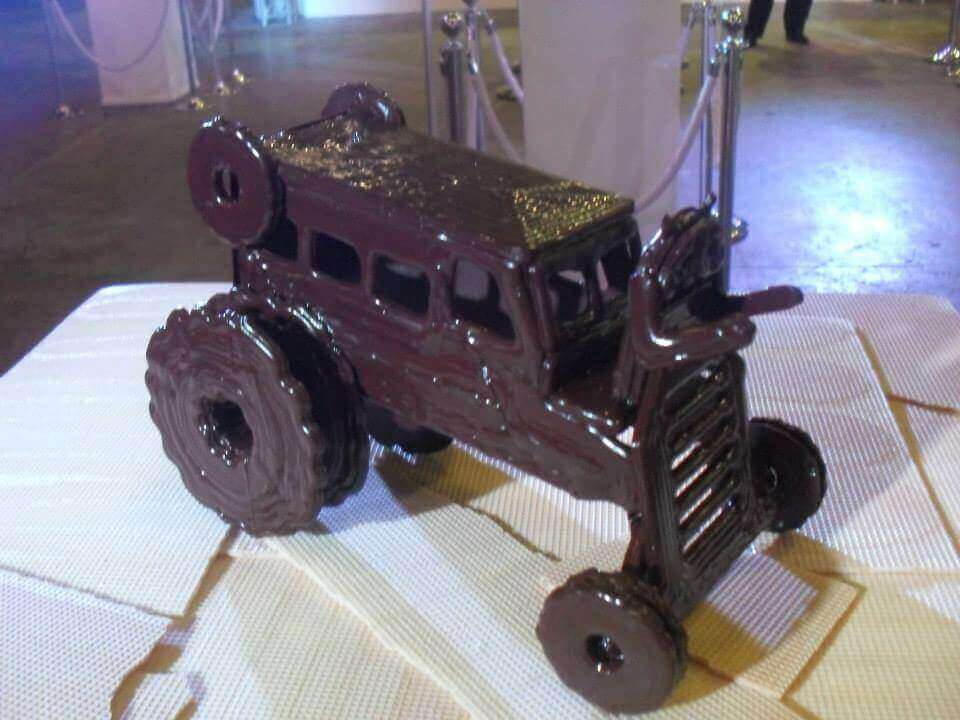

Hans surpassed all of these limits and the way he did it makes him a modern day tech-hero. He spent years working on his first custom 3D printer, which used multiple nozzles to create large chocolate decorations. He thus realized that the barrier that still keeps 3D printing from being truly and widely useful to the average person is the size of the printer, or the size of the printed object if you want. While leading 3D printer manufacturers are racing to deliver high precision, ultra-high resolution products, Hans is perfecting a 3D printer – which he named Cheetah for the printing speeds it is able to achieve – to print large one-piece objects.

While Hans has used his large 3D printer to work with concrete structures, he recently adapted it to work with very affordable ABS plastic pellets. Among the first objects to be printed out of this extra-large printer is the full-size lawnmower, something many people around the world could build in a matter of hours at a very low cost.

Functionality Before Appearance

Hans’ 3D printer is not about resolution and color, but more about usability and functionality. Who cares if the lawnmower doesn’t look as cool as the excessively overpriced commercial counterparts, if it works well? And why feel bad about millimetric imperfections when you can always re-print any broken part? Aesthetics are bound to improve with time anyway, but what we are missing at the time is a truly affordable and efficient mean of production for the home

That’s probably what Hans thought after the media success of his lawnmower, so he decided that his next product would be a vacuum vase! Using the same 3D printer, mr Fouche was able to create (in just under four hours) a fully functional vacuum cleaner that also dubs as a flower pot. Since all vacuum cleaners stay inside the house, why not give them a decorative value?

Hans has been following an open approach to the further development of his creations, offering his 3D printing files for free, allowing for a community of users/testers to locate design flaws, provide feedback and build more efficient vacuums and lawnmowers (and whatever else is coming round the corner) in the future. Such an approach clearly indicates that his intentions are to spread the benefits and conveniences of the technology instead of making personal gains. Although the Cheetah is not currently available for sale, it is only a matter of time for such machines to start shaping our everyday items.

You can contact Hans Fouche via his Facebook page; also you find an interesting article on him in the Kempton Express.

License: The text of "Hans Fouche Shows What a 3D Printer Can Do" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.