Researchers at MIT engineer 3D printed pasta sheets that transform into 3D shapes when dunked in water; could save food shipping costs.

Don’t Miss: Soft 3D Printed Robot Traverses Sand, Enters Your Nightmares

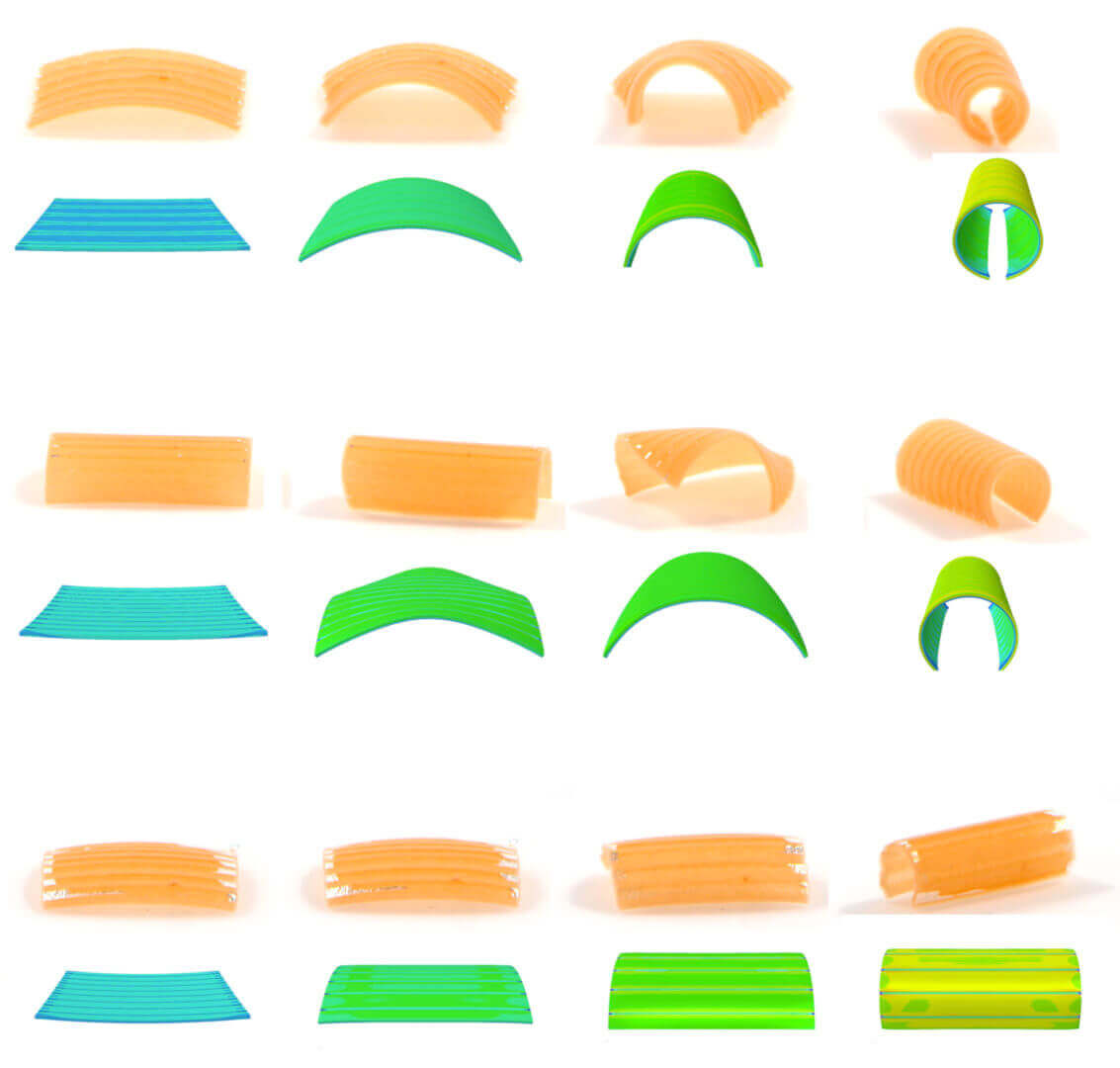

MIT researchers from the Tangible Media Group have created food that can transform its shape when water is added. Edible origami is perhaps the best way to describe how it works; flat sheets of gelatin and starch that instantly sprout into three-dimensional structures when submerged in water.

This includes common pasta shapes such as macaroni and rotini, but the 3D printed pasta can also be made to fold into the shape of a flower or other unconventional forms.

Exploring the culinary potential of 3D printed pasta, the scientists went to the head chef of a high-end restaurant in Boston. Together, they created flat discs that wrap around beads of caviar, similar to cannoli. They also devised spaghetti that divides into smaller noodles when dunked in hot broth.

The team describe their shape-morphing creations as more than just culinary performance art. It’s also a practical way to reduce food-shipping costs. The edible films could be stacked together when shipped to consumers, and then “pop” into their final shape when immersed in water.

The researchers presented their work in a paper this month at the Association for Computing Machinery’s 2017 Computer-Human Interaction Conference on Human Factors in Computing Systems.

3D Printed Pasta that Changes Shape Could Reduce Shipping Costs

Wen Wang is a co-author on the paper and a former graduate student and research scientist in MIT’s Media Lab. He says:

“We did some simple calculations, such as for macaroni pasta, and even if you pack it perfectly, you still will end up with 67 percent of the volume as air. We thought maybe in the future our shape-changing food can be packed flat and save space.”

So how is the shape-shifting pasta made? Wang and his colleagues put together a flat, two-layer film made from gelatin of two different densities. The top layer is more dense, and thus able to absorb more water than the bottom. When the entire structure is put into water, the top layer curls over the bottom layer, forming a slowly rising arch.

But the researchers needed a way to control how the structure bends. This is so they could create different three-dimensional shapes from the gelatin sheet. They eventually settled on 3D printing strips of edible cellulose over the top gelatin layer.

The cellulose strips naturally absorb very little water, and they found that the strips could act as a water barrier. This controlled the amount of water the top gelatin layer is exposed to. By printing cellulose in various patterns onto gelatin, they could control the structure’s response to water and its ultimate shape.

The researchers used a laboratory 3D printer to pattern cellulose onto films of gelatin. But for mass production, they reckon a similar effect could be achieved with more common techniques like screenprinting.

Coming soon to a supermarket near you; Alphabetti Spaghetti with secret messages revealed only during cooking? We’re looking forward.

Source: MIT News

License: The text of "This 3D Printed Pasta Changes Shape When Dunked in Water" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.