High schoolers joined SD Mines’ Research and Engineering Apprenticeship summer program to make 3D printed rocket propellant.

How do you remember your childhood summers? Perhaps there were a lot of trips to the local pool and long, relaxing days in the sun. It’s unlikely many of us spent hours in laboratories, laboring over 3D printers and test tubes.

However, high school students in South Dakota spent their summer at SD Mines. Their cause is a noble one and by sacrificing long relaxing hours, they helped advance science through the Research and Engineering Apprenticeship (REAP) program.

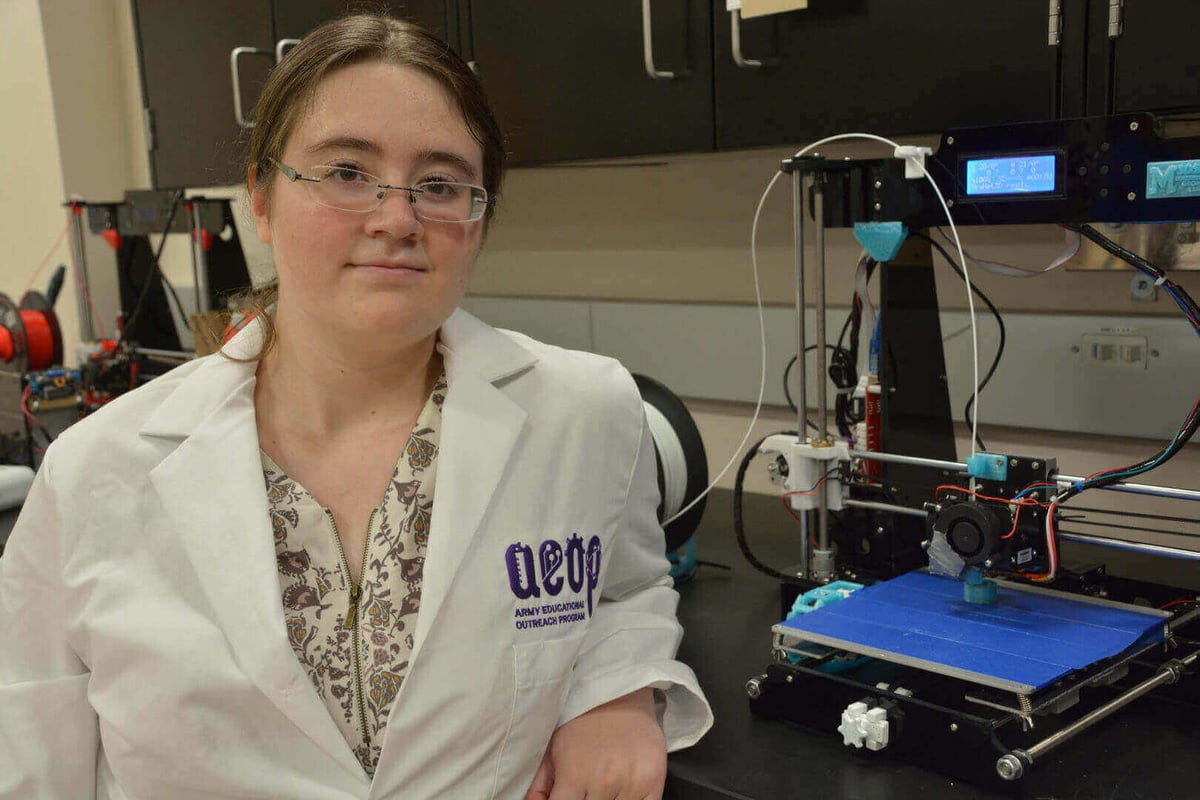

SD Mines was sponsored by the Army Education Outreach Program meaning they were able to offer the program to high school students. These students conducted research for five to eight weeks with help from both graduate students and faculty.

During this time, students were able to learn, research and develop their own projects. One student from Stevens High School, senior Rebecca Watts, spent her summer working on 3D printing rocket propellant. She was looking at the burn characteristics and has a huge goal of one day 3D printing a rocket engine. Watts said:

“I really had no idea how incredible 3D printing can be, how helpful it can be. I can 3D print things that are almost impossible to weld or put together any other way, so it opens up a whole realm of possibilities in the future.”

Making 3D Printed Rocket Propellant at Summer Camp

While developing rocket propellant, Watts learned about the possibilities of someday being able to 3D print energetic materials, including explosives and rocket fuels. Her work was also sponsored by the SD Space Grant Consortium.

As well as Watts’ work on 3D printing rocket propellant, another high schooler from Central High School, Enrique Mandas, researched a method to create a bonded plastic material for use in aerospace and automotive industries.

He worked on fusion bonding using an ultrasonic spot welder. This machine creates polypropylene by using energy from high-frequency vibrations and fusing plastics together. The resulting material offers an alternative to heavy metals currently used.

Mandas focused on creating the strongest bond possible by optimizing the joining process. He explains: “You become a changemaker once you become a scientist or engineer. You can discover something big that will change the world or something small that will change your life.”

However, Mandas and Watts aren’t the only students to be involved in REAP. In fact, around 120 students from over 50 universities take part every year. You can find out more about the program, here.

Source: SD Mines News

License: The text of "High School Students Make 3D Printed Rocket Propellant" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.