Researchers from the University of Delaware have developed a 3D printed smart window that could help cool the masses.

As climate change continues to heat up the world around us, researchers are coming up with novel solutions to help keep populations cool. To accomplish this, a research team from the University of Delaware recently developed 3D printed smart glass.

The glass, which can switch between reflective and clear, could potentially be used to make switchable windows for buildings to make them more energy efficient during both summer and winter.

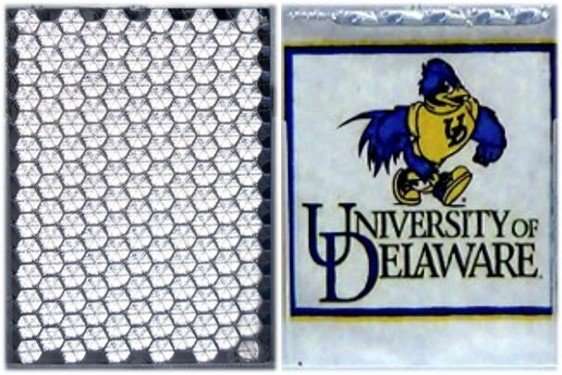

The smart windows come with a 3D printed plastic panel that is retroreflective, which means that light is reflected back to where it originated from rather than being scattered.

The panel is covered with a chamber that fills with methyl salicylate – a fluid with optical properties – which is responsible for the retroreflective properties of the window.

In creating the plastic panels, the research team employed a commercial 3D printable material and refined the plastic’s properties in post-processing. Keith Goossen, leader of the team at the University of Delaware, explains:

“Without 3D printing, we would have had to use a molding technology, which requires building a different mold for every different structure. With 3D printing, we could easily make whatever structure we wanted and then run experiments to see how it performed. For commercial production, we can use standard injection molding to inexpensively make the retroreflective panels.”

Once the panels had been designed they underwent repeated testing, including optical tests to ensure the smart windows would work as proposed. The smart window was also found to be rather durable – able to undergo thousands of cycles of switching without degradation.

With 3D printing, we could easily make whatever structure we wanted and then run experiments to see how it performed.

3D Printable “Smart Glass” Could Reduce Heating and Cooling Costs

Goossen expects the smart glass to cost just a tenth of what existing smart glasses cost, due to the lower cost of manufacturing the 3D printed plastic parts. Available smart glasses also feature electro-optic technology for switching between clear and reflective states which increases their pricing to $100 per square foot.

The team considers one of the most promising applications for the smart glass to be car windshields. Goossen adds:

“You can’t use today’s commercially available switchable glass for this application because in the darkened state the windshield still absorbs sunlight and becomes hot. Because our glass is retroreflective in the non-transparent state, almost all the light is reflected, keeping the glass, and thus the car, from getting hot.”

In addition, the smart glass offers excellent potential for skyscraper development. Most buildings contribute directly to city warming by reflecting light toward the street. But, this unique material would reflect the light back toward the sun instead.

This recent development could even be used to create smart windows or roofing structures, which could help cool properties during summer or in warmer climates. At the same time, the smart glass can be switched to non-reflective or dark during the winter which helps to lower heating costs.

While this research is certainly exciting, there is still more work to be done before you’ll be modeling your home with this smart glass. Since the methyl salicylate material is susceptible to freezing, the team is currently developing additional fluid materials that can be utilized as well.

Source: Phys.org

License: The text of "This 3D Printed Smart Glass Can Keep You Cool in the Summer" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.