Got a noisy office, home or studio? These 3D printed sound absorbers will get you professional results… and relief to your ears.

If you enter a cinema, you’ll notice that the walls and the ceiling differ from your home. Usually planned and built by acousticians, cinemas, concert halls, professional conference rooms use sound absorber panels. They are great for dispersing unwanted noises, echoes and early reflections, so the movie soundtrack sounds exactly the same from any seat in the theater.

To reduce boomy bass frequencies, these panels use the principle of Helmholtz resonators (commonly known as “bass trap”, they look like cones with an open top). For higher frequencies, tiny holes in irregular panels absorb and disperse unwanted frequencies.

Yes, professional sound absorber panels work great. Unfortunately, they are expensive. You can pay up to $2000 for a single panel; which this leaves little room for experimentation. Also, they can’t be produced on-site. This is where 3D printing comes to help.

3D Printed Sound Absorbers: Print Them For Free

Paris-based Designer Julien Dorra came up with DIY sound absorbers. The self-proclaimed “creative technologist” used OpenSCAD to make a modular system of 3D printable sound absorbers. Clever, because you can address different frequency problems with different panels. So far, Dorra designed these parts:

- Micro Perforated Panels with cone backing

- Micro Perforated Panels with 3-length tunnel backing

- Perforated panels with coplanar coiled air chamber – this allows low-frequency absorption with very thin panels (preliminary, brittle implementation)

- Destructive interference – hard to tune, still quite large (not yet implemented)

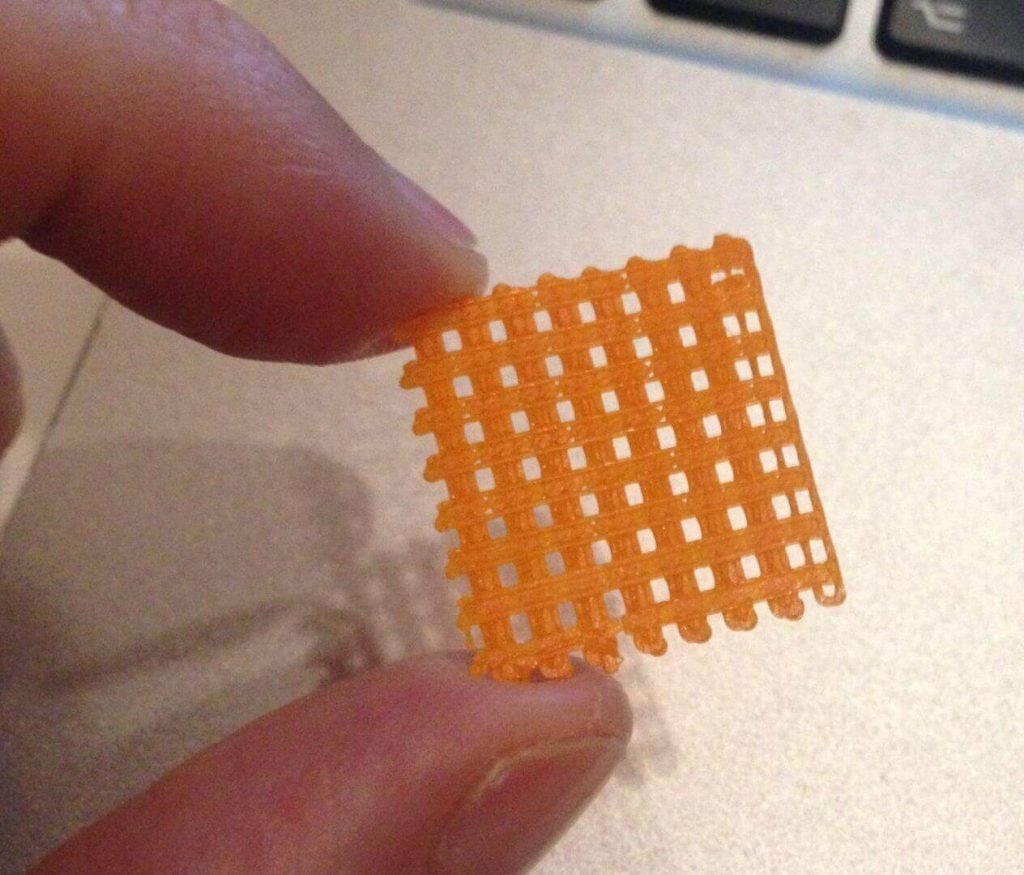

One of the challenges Julien Dorra faced was the printing of the sub-millimeter holes (the one‘s that absorb high frequencies). This is a real challenge for any decent home 3D printer. He came up with a great solution by 3D printing two overlapping layers where the cross-pieces form holes of the required size.

3D Printed Sound Absorbers: Cheap Enough For Sonic Experiments

All you have to do is to download the files and start printing. If you don’t have a 3D printer, you can have the parts printed by a professional 3D printing service (get the best price here).

The absorbers aren’t expensive at all, all you need to invest is some time for the prints. Julien Dorra came up with a calculation:

“Based on premium PLA at retail price, back of the napkin estimation of filament cost start around 50€ / $50 for 1㎡ of micro-perforated panels with segmented 5cm backs. This go up to 100€ / $100 for 1㎡ of 5cm cone-based back. Use of cheaper filament or bulk purchase would drive the price lower, at around 25€ / $25 for 1㎡ of micro-perforated panels.”

If you want to dig deeper, please follow this link to Julien Dorra’s GitHub Page. You’ll find all the resources there.

(Source: Fabbaloo)

License: The text of "3D Printed Sound Absorbers Will Bring Relief To Your Ears" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.