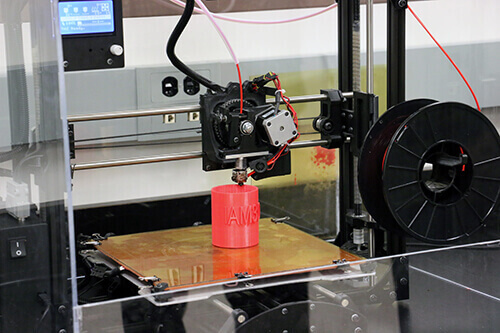

Two students are using 3D printing to combat the Flint water crisis. Can 3D Printed water filter “The Trunk” make a difference?

The Flint water crisis has mostly been a major debacle, and no one knows that better than Flint residents. Two students at local Kettering University have designed a 3D printed water filter for their city — and also for the American Society of Mechanical Engineers IAM3D Challenge.

The city of Flint first discovered lead contamination within their water source back in September 2015, and the State of Michigan declared a State of Emergency in January. Residents were instructed not to use the water without a filter — but some of those freely provided filters didn’t even properly fit certain faucets.

3D Printed Water Filter Makes Safety More Accessible

Students Kyle Mikols and Ryan Webster created “The Trunk” water filter in their rapid prototyping class, in a bid to create an accessible “foolproof” filter that could fit all, not just most, faucets. Their mission statement:

“The design files can be readily accessible on local government or disaster relief organization web pages. This open access would allow individuals with 3D printers to print them as needed or emergency/crisis response agencies could mobilize 3D printing farms to meet demand in a crisis.”

The Trunk prototype took 16 hours to print, and is not just for Flint. The students realize that Flint is just one case, and the real use of such an adaptable faucet has more more widespread applications.

Webster notes that The Trunk’s printability also means adaptability. Lower costs combined with the chance for designers to make modifications could lead to interesting, and practical, results.

The pair is still working on their prototype to meet the submission deadline for the IAM3D Challenge on April 15. Read all about it on the Kettering University website.

License: The text of "Flint Water Crisis: Students Create 3D Printed Water Filter" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.