3D printing (or additive manufacturing) means creating a three-dimensional object in one of various processes. What you need is a 3D printer, the printing material and a digital 3D model. The object is created by placing one layer of the printing material upon the other.

3D Printing Process

First you need a 3D model. This is a digital file – in the standard STL or OBJ file format – that is either created in a CAD (computer aided design) application or produced using a 3D scanner (or a digital camera plus software). In a process called fixup the model file is then checked for errors.

Next, the file is processed by a slicing software that converts the model into a series of thin layers. The slicer creates a G-code file containing instructions for a particular 3D printer. This file is fed to the 3D printer that starts creating the object layer by layer. The layers are extremely thin (typically 0.1mm and less) – the thinner the layer, the less visible is the layering in the object. In almost all cases, final finishing is required to remove excess material or support material and to sand the surface.

The Most Popular 3D Printing Methods

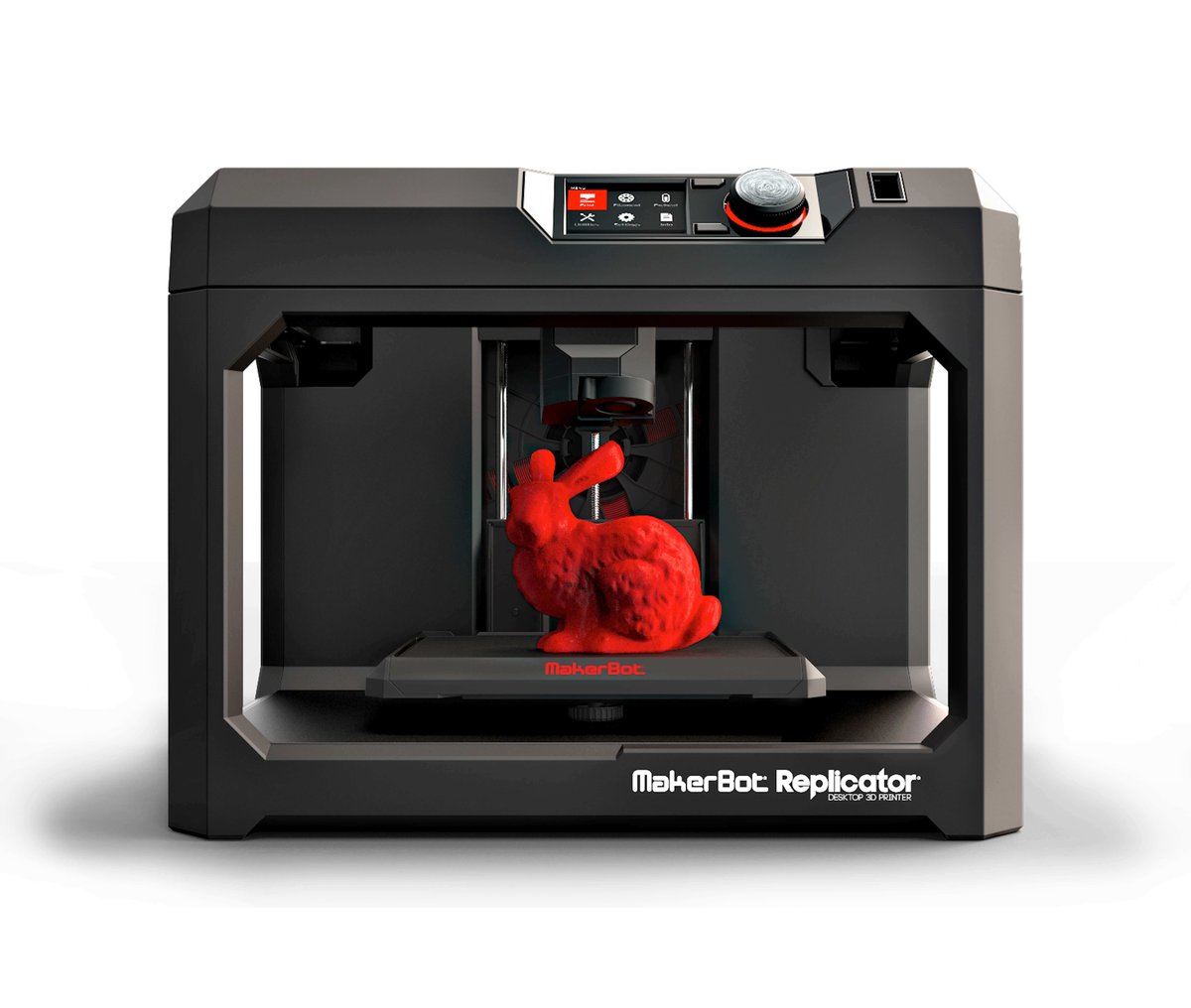

The method employed by most desktop 3D printers is known as Fused Deposition Modeling (FDM). In this technique, a hot glue gun is used to melt the print material and to extrude it through an active toolhead, the extruder. The print material, typically thermoplastics, sometimes porcelain or metal clay, is fed as a thin wire, called filament, to the 3D printer nozzle.

There are other “printing” methods using different materials. The principle is generally the same no matter what the technique: The object is built layer by layer from the bottom to the top. Though not in all methods the material is heated and forced through a nozzle: Some methods involve lasers or stereolithography and usually some powdery material.

The most common methods are:

-

FDM (fused deposition modeling) – see above.

-

SLS (selective laser sintering) uses a laser to sinter powdered material (e.g. metal) by aiming the laser at points defined by the 3D model; the laser binds the material together to create a solid structure.

-

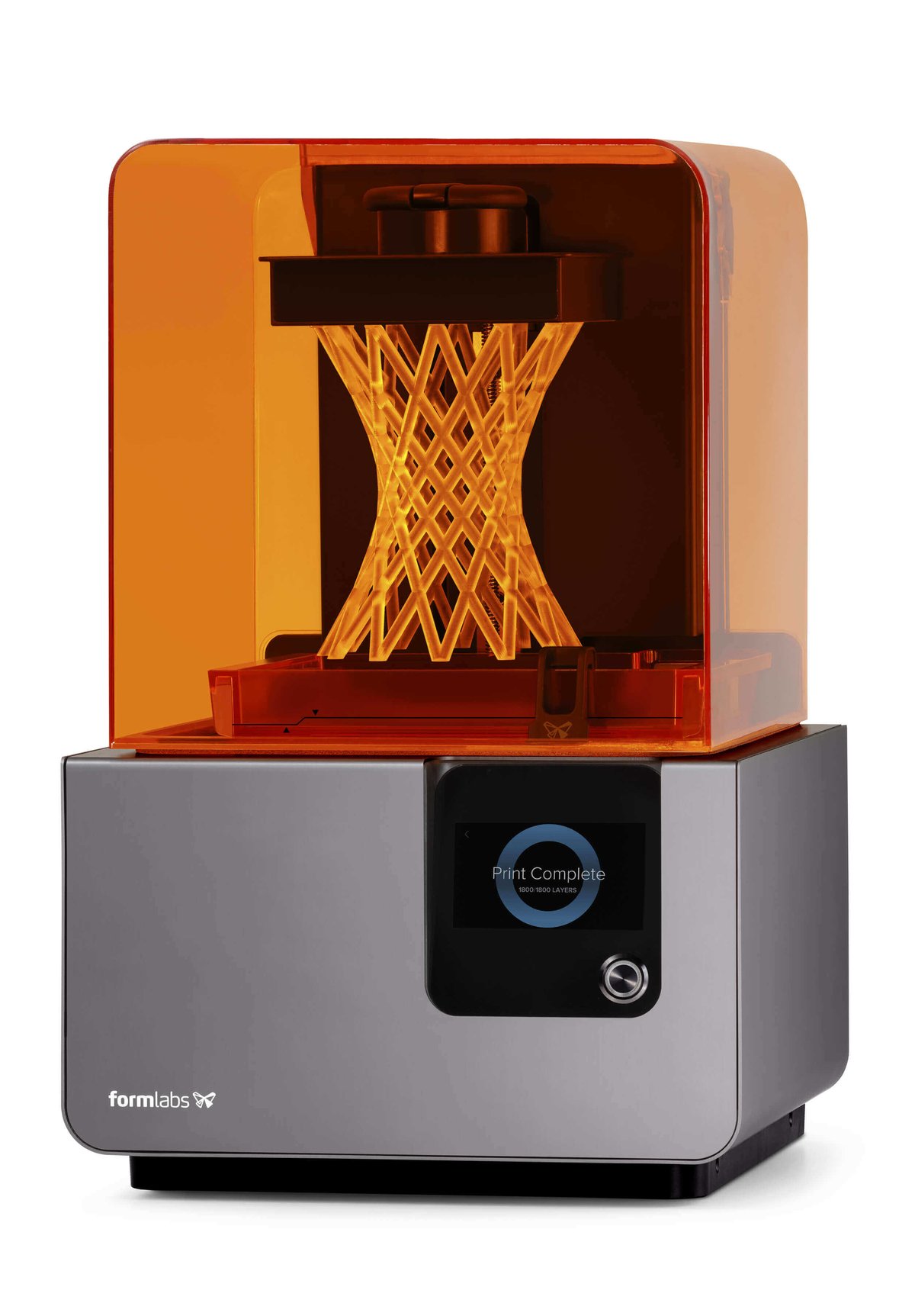

SLA (stereolithography): Here the model is built one layer at a time by curing a photo-reactive resin using a UV laser or a digital projector. When exposed to light, the resin solidifies.

3D Printing vs. Common Manufacturing Processes

3D printing is so to speak the contrary of traditional manufacturing processes which include sculptors, laser cutters and CNC mills or lathes. Such machines start with a block or piece of raw material and remove parts in order to achieve the desired shape.

The main reason behind the popularity of additive manufacturing, which is used in 3D printing, is the fact that you can achieve various complex shapes with ease which would be very difficult, if not impossible, to attain through subtractive manufacturing, as done using laser cutters and CNC machines.

More Info: If you want to know more about 3D printing, just enter “FAQ” in the search field on our site All3DP.com.

License: The text of "How Does 3D Printing Work?" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.