Verbatim, the data storage and recently 3D printing filament company, has launched a new bio-friendly filament called Durabio. The company will be at Formnext this month to discuss this latest development.

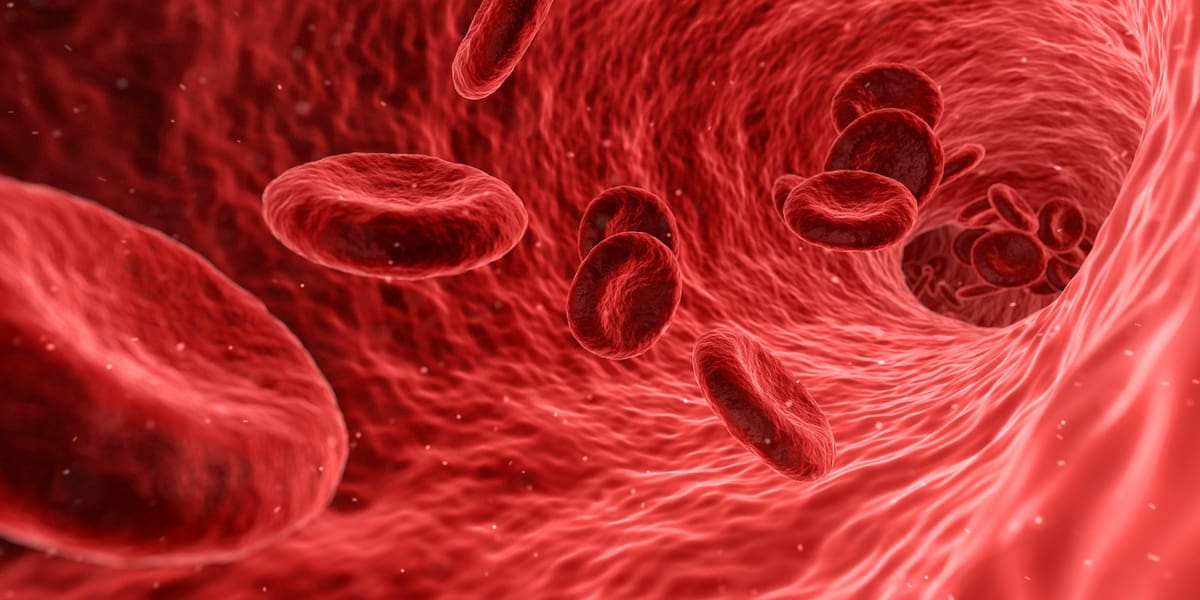

Researchers from the University of Colorado Boulder have developed a 3D bioprinting technique that enables local control over an object's firmness. It could one day be used to create patient-specific artificial vessels and organs.

Australian based metal additive manufacturing company, Titomic Limited, has partnered with the Innovative Manufacturing Cooperative Research Centre (IMCRC), CSIRO and RMIT University in a $2.6 million deal to meet aeronautical standards for the company’s Kinetic Fusion (TKF) technology.

Apium Additive Technologies, the 3D printing manufacturer, has launched a polypropylene (PP) material to its additive manufacturing portfolio. More news from the company will be announced at Formnext in November.

Lockheed Martin, the aerospace and defense giant, is the first company to be certified for Additive Manufacturing safety by UL, the global safety consulting and certification company.

Manuel Oliver, the father of a student who was killed in the school shooting in Parkland, has 3D printed a life-size sculpture of his son "Guac". The sculpture is a protest against the pending legality of 3D printed guns and was put on display in Times Square.

Classic chocolate making techniques meet 3D printing in the Kickstarter campaign "Chocolate for the Digital Age". Chocolatier Ryan L Foote is hoping to raise $7,100 to create nature-inspired shapes with daring, locally-inspired flavors.

This week, the U.S. Patent and Trademark Office released a series of granted patents made by Apple. One of the 46 patents granted shows a new way to create 3D print models.

The Japanese electronics manufacturer Mitsubishi Electric Corporation has announced the development of a new metal additive manufacturing process. Dubbed as "dot forming technology," the technique combines laser, CNC, and CAM technologies to produce near-net metal parts.

Now launched on Kickstarter is a 3D printed knitwear campaign by The Girl and the Machine which aims to reduce consumption by providing high quality, luxurious merino wool jumpers made to meet your tastes and sizing exactly.

Askja Audio, a French company creating systems for audiophiles, reveals how important 3D printing processes are to its manufacturing process.

The global tech titan HP is teaming up with the Nanyang Technological University in Singapore to construct an $84 million Digital Manufacturing Lab that will focus on researching 3D printing, materials, AI, and more.

The international waste-to-product company, Renewi, and Dutch recycling filament specialist, Refil, are collaborating to create a high-quality HIPS filament that is made from recycled refrigerators.

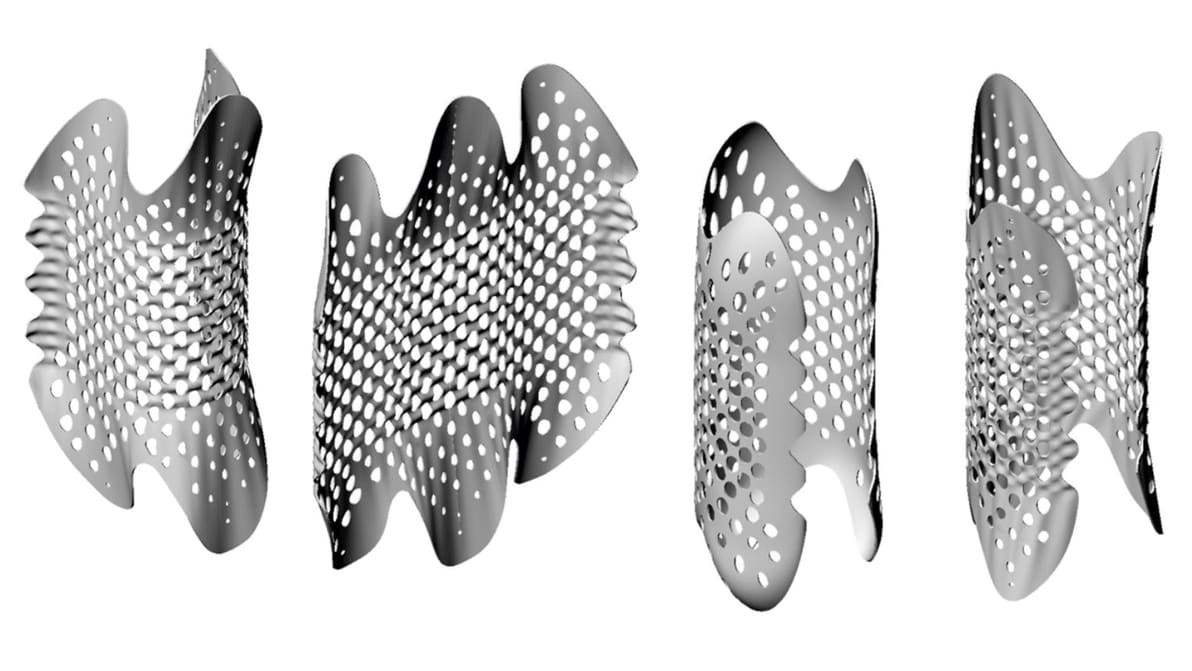

Uniform Wares, Swiss Made Luxury online store for watches, recently collaborated with Betatype, the additive manufacturing company, to create a unique titanium watch strap using 3D printing.

Say goodbye to conventionally shaped rectangular or cylindrical batteries. Scientists from Duke University and Texas State University are in the early stages of developing 3D printed lithium-ion batteries which could offer interesting possibilities.

Two architects from studio Tonkin Liu have developed a 3D printed stent prototype that can adapt to a patient's throat after they've undergone tracheal transplant surgery.

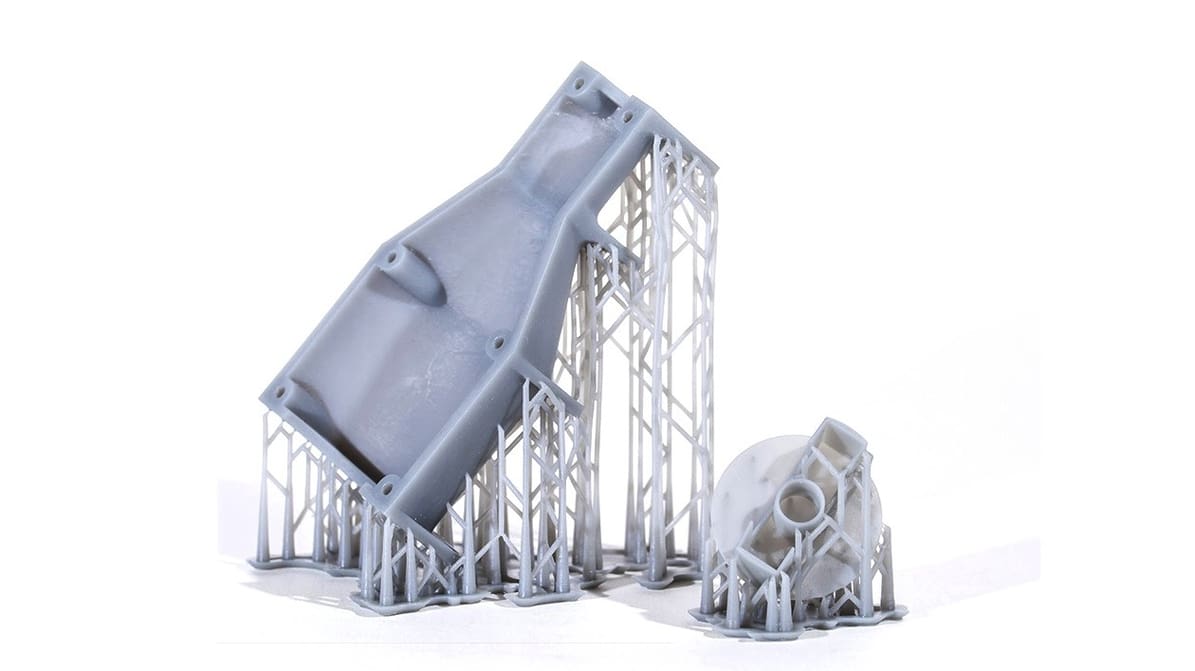

The latest "Digital Manufacturing Trends" report for Q4 2018 from 3D printing network 3D Hubs has been released. In this quarter, we see new printers rising, Austin take over New York as the second 3D print city, and the SLA/DLP market share increased.

The renowned Massachusetts-based shaving company Gillette is working with Formlabs to pilot its new Razor Maker concept, aiming to give customers the ability to personalize and 3D print custom razor handles.

A team out of the University at Buffalo has developed PrinTracker, a system that traces 3D prints back to their source machine. Considering the recent 3D printed gun controversy, the arrival of the technique seems timely.

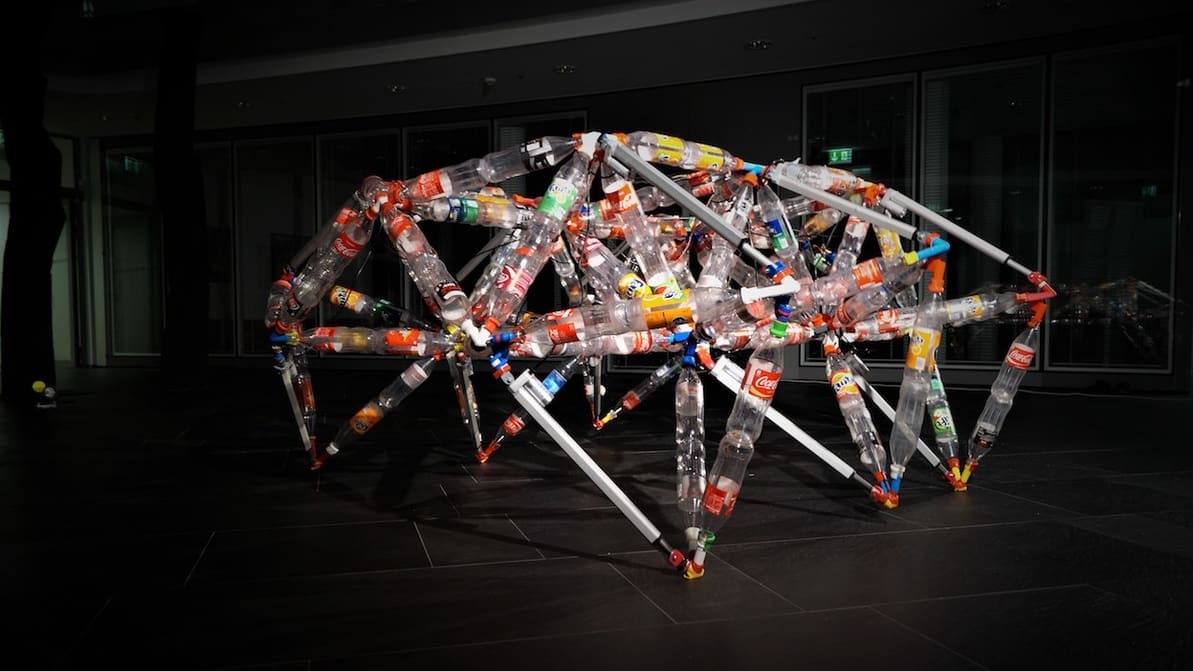

Scientists from the Hasso Plattner Institute in Germany have developed an integrated end-to-end software solution called TrussFormer. It allows users to design large-scale kinetic structures produced from plastic bottles and 3D printed connectors.