Forward AM, the 3D printing solutions brand from chemical giant BASF, launched the Innovation Award in 2021 to shine a spotlight on startups developing new applications with 3D printing. With the focus strictly on applications — startups developing 3D printers, software, or materials are not eligible — Forward AM will connect these start-ups with leading investors, industry experts, and fellow entrepreneurs to grow their fledging companies and bring more 3D printed products to the mainstream.

The 16 semi-finalists and their products address needs in healthcare, sports and fitness, manufacturing, consumer goods, housing, and more, with innovations designed to disrupt how things are currently made with 3D printed options that improve performance, efficiency, quality, speed, and costs.

The award is organized in cooperation with IAM 3D HUB and sponsors include HP, Photosentcric, Sculpteo, Stratasys, AMT, and Atum. Likewise, AM Ventures, Asimov Ventures, MatterHackers, MGA, and Women in 3D Printing are partners of the competition. Each of them will bring their specific expertise to the competition.

On Sept. 6, four finalists from the 16 will be selected to each receive €10,000 (about $10,000) and on Sept. 30 they will present their start-up to the jury and the public for a chance at the €50,000 prize.

Semi-Finalists

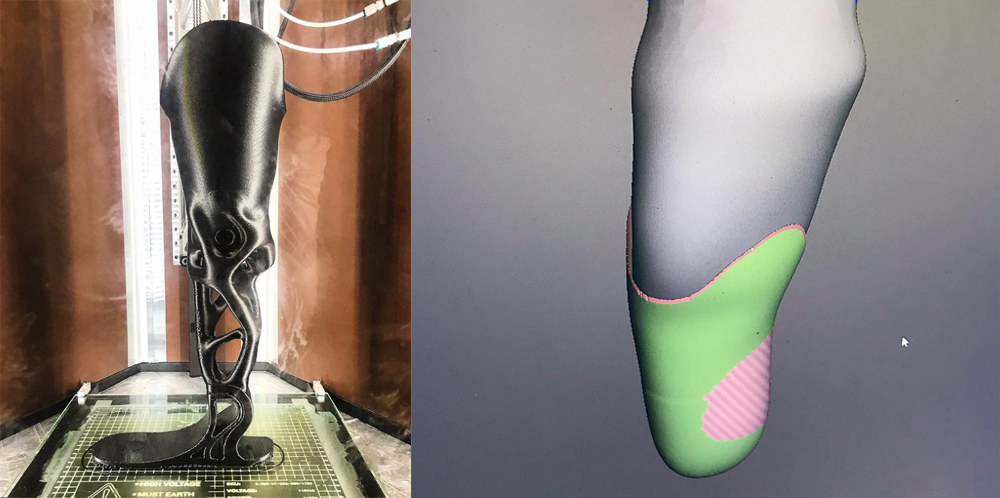

Act’ble

Act’ble has developed 3D printed soles for ballet pointe shoes to improve the sustainability and health of dancers. The geometry of the act’sole allows for the shoe to be danceable without having to be broken in. Additionally, the shoe is based on a modular system that allows the part that breaks first to be replaced, and therefore, the parts which last longer are sustained.

4Devices Medical

4Devices Medical has developed a new technology for 3D printing of thermoplastic and/or shape memory polymers (4D printing) at a micro/milli-scale and with a complexity never used before. With this solution, 4Device Medical will introduce to the market new surgical devices such as the 4D stent to treat hydrocephalus in babies, a long-lasting solution that minimizes surgical operations and increases a patient’s quality of life.

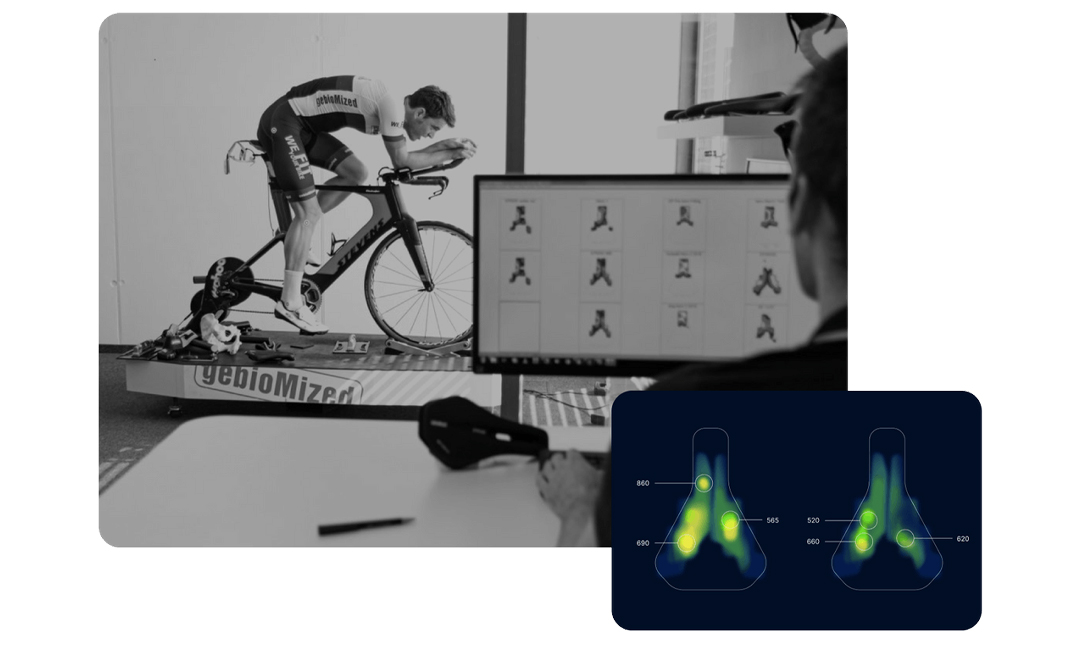

Mootion

Mootion makes mass customized, 3D printed cycling saddles that enhance ergonomy, comfort, and performance. The company combines hundreds of data points with athletes’ personal biomechanics and cycling performance to produce products that help them perform better and enjoy the cycling experience more.

Archytas Automation

Archytas Automation is bringing affordable automation robots to local micro-factories in underserved areas, which are the ones typically affected by job loss due to manufacturing automation. The company’s 3D printed robotic arms make automation more accessible.

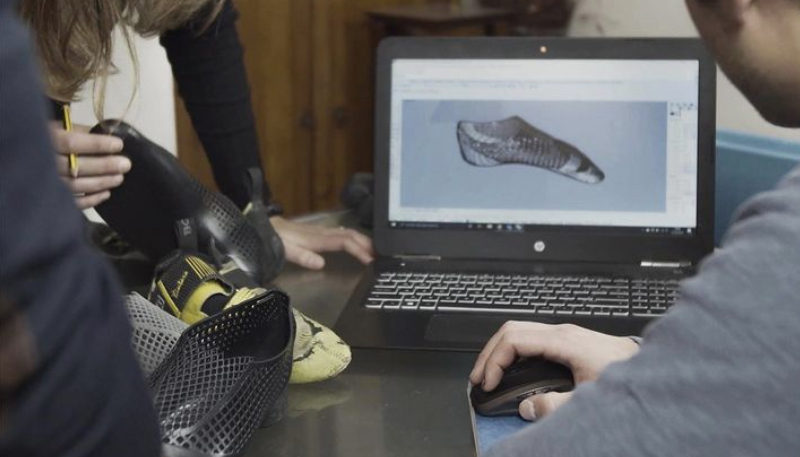

Athos

Athos has created a 3D printed custom-made climbing shoe to improve the comfort and performance of climbers. By using 3D printing, each climbing shoe is tuned to the user’s feet shape, needs, and type of performance. Mass customization and production on demand enable the company to develop a more responsible way of consumption and manufacturing.

Azure Printed Homes

Azure is 3D printing residential structures with recycled PETG plastics. The company aims to reshape the way we build homes, ADUs, and backyard studios by bringing 3D printing technology and recycled materials together to create truly sustainable living in a modern and beautiful design at a fraction of the time and cost, plus with a positive environmental impact.

ColorForge

ColorForge is the first, patented binder-jetting 3D printing process that manufactures custom color cosmetics and product casings simultaneously with no minimums or waste. The personalized powder-based cosmetics are 3D printed on demand in a biodegradable shell with no wasteful metal packaging.

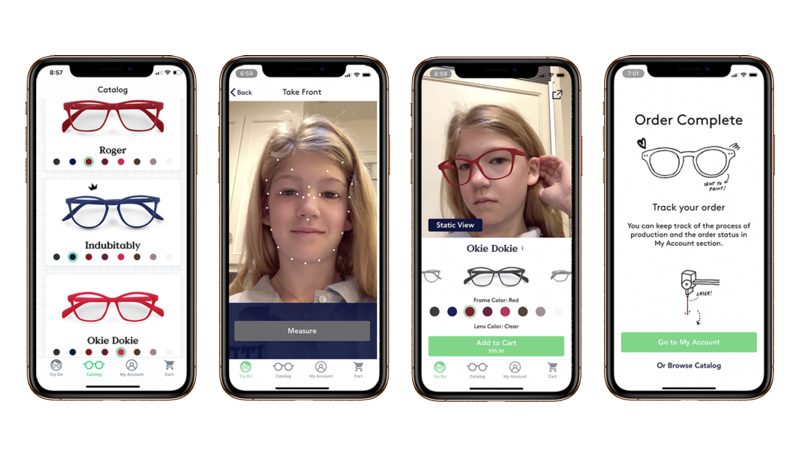

Fitz Frames

Fitz Frames 3D printes corrective eyewear frames that are custom fit to each customer, including children. Fitz Frames’ technology measures all the facial nuances—cheek angles, nose width, ear height—to ensure a precise fit. Customers can pick a frame from a large assortment, and the glasses, with corrective lenses, are shipped out, all at an affordable price.

Kollide

Aptly named Kollide 3D prints affordable and customizable helmet liners for American football players. Each one is customized according to fit and field position of the player to ensure a better mechanical response to linear and angular impact. to reach a higher level of protection. The company’s 3D printed materials provide a new level of protection to weight ratio and air circulation, improving athletes’ comfort and performance.

Limber

Limber uses digital design and 3D printing to bring affordable prosthetic devices to those in need. Using a digital workflow and 3D printing, Limber gives physicians the tools to efficiently create personalized prosthetic limbs at less than one-tenth of the cost of comparable devices.

Moi Dental

Moi Dental makes the only reinforcements in the world designed for dental prostheses and orthodontics that are 3D printed and powered by continuous fiber manufacturing technology. Created by experts from the Politecnico di Milano and dental professionals to improve and advance patient care.

Reset

Reset is a provider of 3D printed alternatives to dental implants and an affordable way to replace missing teeth without going to the dentist.

Aimed at the millions of Americans without access to dental care, Reset offers an at-home impression kit, partner dentists to design treatment, and 3D printed replacement teeth.

Digifab HipCare

Digifab makes personalized 3D printed splints, as a substitute for plaster in hip dysplasia in babies.

Ocupeye

Ocupeye is developing a 3D printed prosthetic eye and workflow that will improve eyecare professionals’ efficiency and provide more comfort to patients.

Odapt

Odapt is developing a reusable and customized wafer for two-piece ostomy bags that adapts to any shape of stoma and brings customization to medical care.

SmileShade

SmileShade is a lattice-structured 3D printed titanium alloy dental implant bar that saves material, time, and weight when it comes to

License: The text of "16 3D Printing Entrepreneurs Reach Semi-Finals at Forward AM Innovation Award" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.