When maker and engineer Replayreb came up with the idea of selling lightsaber pen tops on eBay and Etsy, he knew he’d need a way of creating more than just one print at a time.

First, he tried printing multiple pen tops at once but found that the results weren’t as good as when he printed just one at a time. Annoyingly, he explains that each print takes 30 minutes which meant he always had to be “on call” to remove the model and manually start printing the next.

So, to solve this problem, Replayreb came up with an ingenious hack to make sure he could continue printing even when he’s not around. He explains on Thingiverse: “I wrote a Winbatch script that prompts you to select a gcode file and asks how many copies you want to print. Then it takes that gcode file and pastes multiple copies of it into another file and inserts some gcode in between the copies called eject.gcode.”

The eject.gcode first homes the print head, then raises the Z-axis by just a couple of milimeters. Finally, the head moves to knock the printed model off the print bed.

However, Replayreb points out that this hack isn’t a “turn-key solution” and you’ll need some understanding of g-code to “trick” your printer. As well as this, the process only works with small models that have a small base and can easily be pushed off the print bed.

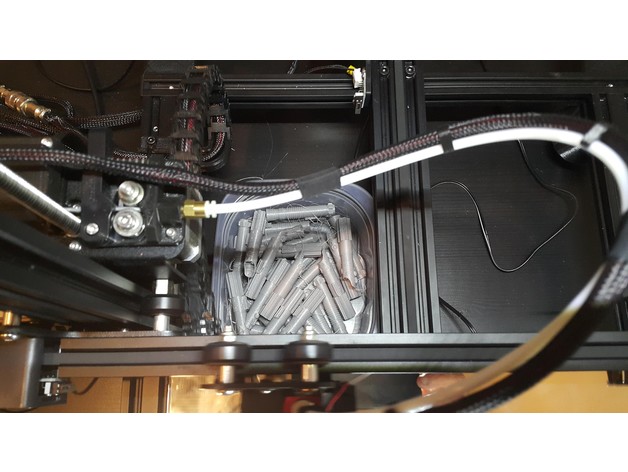

But, if you can overcome these complications, it’s a pretty neat hack. And, of course, you can’t remove every print from the bed. But watch how the print head easily knocks off the 3D model into a box in the video below:

Automating a 3D Printing Process at Home

For Replyreb, this solution works perfectly and he’s able to monitor his mini-factory at home while he’s out at the office all day. To do this, he uses his phone via my OctoPi and webcam.

Impressively, in an update on Thingiverse, he explains that recently, while he was out, a batch print job finished. But, it was simple to log into his PC via VNC and generate another batch. As the print bed was clear, he was able to start printing remotely without even being in the house.

If you’d like to adapt Replayreb’s hack for your own printer, he has made the eject.gcode available on Thingiverse. However, you’ll need to tweak it for your own 3D printer. He explains: “I would first remove or comment out the temperature commands and run the code by itself to see where the print head ends up.”

Currently, he is printing on a smooth mirror as PETG will both stick and pop off more easily than if he was using a sanded mirror or a piece of painter’s tape.

There have been many ideas in the past for ways to get a print to pop right off and the printer to continue printing. But, this simple little hack is one which doesn’t require extra hardware and is great for anyone running a 3D printing business from home while going to work all day.

If you have no understanding of g-code and just need a way to get your prints to pop off your print bed, check out this post on All3DP. And if you want to drill deeper into g-code, please continue here.

Source: Hackaday

License: The text of "3D Print Multiple Models One After the Other with 3D Printer G-code Hack" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.