After more than four decades of making high-end walking and safety footwear, Grisport took a big leap. The Italian manufacturer upended its processes and is replacing its expensive aluminum injection molds with in-house 3D printed ones that produce the same result at a tenth of the cost and 50-times faster.

“3D printing is going to change fundamentally the way we bring models and products to the market,” says Giovanni Grigolato, the company’s head of R&D.

Grisport no longer has to worry about producing a shoe design that will generate a minimum sales quantity to justify the €5,000 ($5,500) cost of producing an aluminum mold. At around €500 per 3D printed mold, the company can bring to market more designs. It also opens up the opportunity for producing limited-edition and custom products.

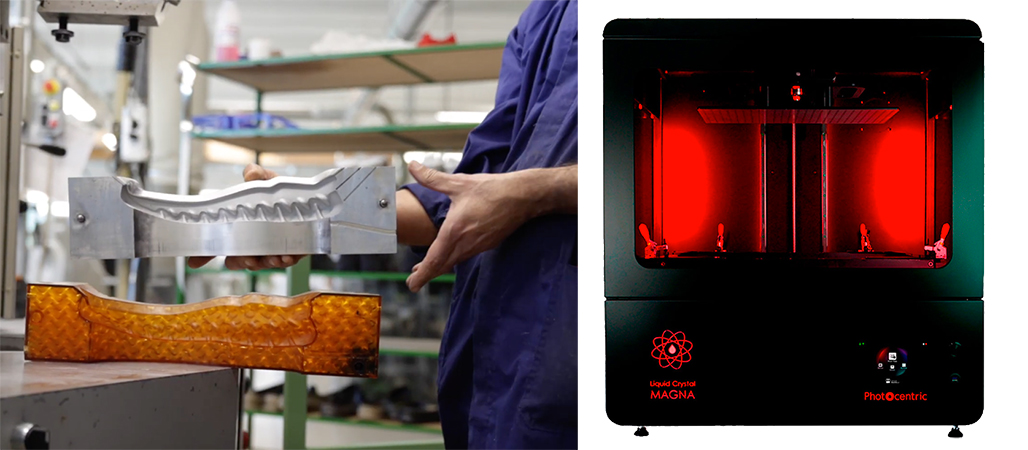

Grisport is one of the leading companies in direct injection shoemaking worldwide, so they know molds. The company researched durable, heat-resistant materials and 3D printing technologies for months before selecting the Photocentric Liquid Crystal (LC) Magna, a large format resin 3D printer, and its HighTemp DL401 material.

“Magna and HighTemp DL401 are transforming the way shoe molds are being made,” says Hanifeh Zarezadeh, product manager at Photocenric. “You can now use the same plastics and the same process as an aluminum mold, but with all the advantages of lower cost and faster to market.”

The material and the printer work together to produce a final mold that has very high strength, hardness, and impact resistance while matching the precision and dimensional accuracy of traditional aluminum molding and machining, Zarezadeh adds.

“HighTemp DL401 is very good for us because it reaches the higher temperatures necessary for PU (polyurethane) injection and keeps them stable,” says Grigolato.

Strength is not the only reason Grisport approved the shift to 3D printed molds. Speed to produce them was also a significant factor, the company says.

Grisport can produce a full shoe mold, which consists of three parts, on its LC Magna in 14 hours. Waiting for an aluminum mold from a third-party provider took weeks or longer.

A faster, cheaper mold means faster prototyping and iterating and, ultimately, faster delivery of a product from idea to store shelves.

Grigolato says that before 3D printing, initial design to the finished product took around four months using a traditional aluminum mold. “But with this new technology, we can do it within one month and a half. Producing a mold in-house with a 3D printer is revolutionary for us.”

Grisport found that designing the mold for 3D printing is fundamentally the same process as designing a mold for aluminum manufacturing. The company is optimistic in its ability to roll out these 3D printed molds into mass manufacturing at the end of its current feasibility study.

License: The text of "3D Printed Injection Mold Replaces Aluminum at a Tenth the Cost" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.