Around 15% of people with diabetes will suffer from diabetic ulcers. Such ulcers form when high blood sugar damages nerves meaning patients can’t feel their feet.

As a result, they may not notice when feet are bumped and skin tissue breaks down, causing ulcers. Up to 24% of people who develop such ulcers are hospitalized and face amputation of their toes, foot or even leg.

However, scientists from Purdue University in the US believe they may have found a way to reduce the risk of amputation. They’ve designed a shoe insole which can help heal diabetic ulcers without restricting patients.

Babak Ziaie, a professor at Purdue explains: “One of the ways to heal these wounds is by giving them oxygen. We’ve created a system that gradually releases oxygen throughout the day so that a patient can have more mobility.”

Treating Diabetic Ulcers with Shoe Insoles

Diabetic ulcers are usually treated by removing the “devitalised tissue” from the wound and then helping the patient take weight off their foot. This typically involves a total-contact cast which provides protection.

The researchers took a slightly different approach and developed silicone-based rubber insoles which could provide oxygen to the ulcers in the cast. The reason for using silicone is that it’s both flexible and has good oxygen permeability.

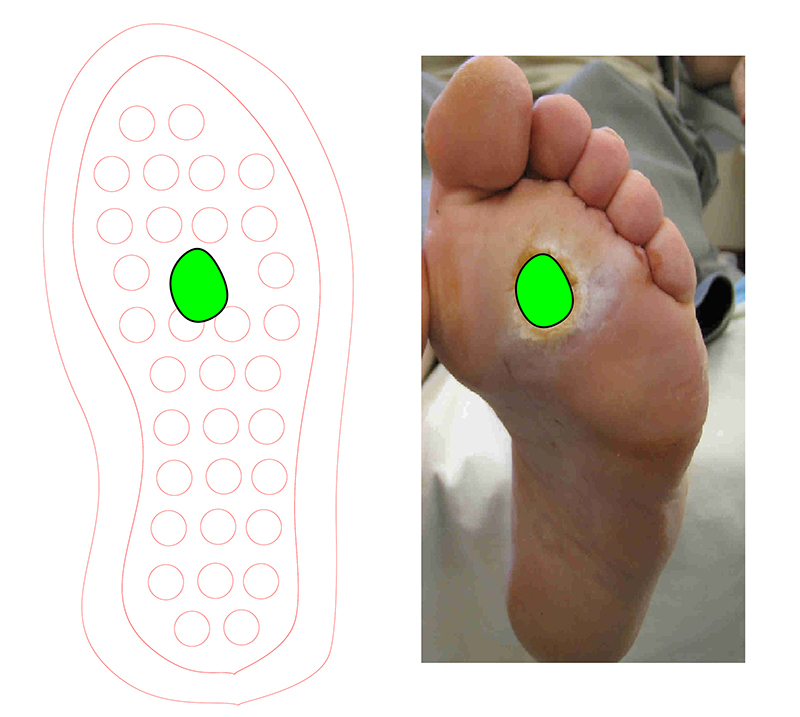

The insoles are be customized specifically to the patient. They are designed with reservoirs which release oxygen to only the patient’s ulcer. For someone weighing 53-81 kilograms, it’s possible to deliver oxygen at least eight hours a day.

They developed the insoles using laser machining. Hongjie Jiang, a postdoctoral researcher at Purdue, explains: “Laser machining helps us to tune that permeability and target just the wound site, which is hypoxic, rather than poison the rest of the foot with too much oxygen.”

However, the researchers hope to be able to develop an insole using 3D printing. This technology will enable them to develop the entire insole in one rather than develop a mold and then laser-machine the pattern.

“This is mass-customization at low cost. We’re wanting to bring this technology to the user by addressing whichever technicalities would be required to simplify the manufacturing flow,” explains Vaibhav Jain, a recent graduate from Purdue’s mechanical engineering master’s program.

Furthermore, the researchers believe that in the future, the patient-specific insoles will be developed from a picture of the foot and a doctor’s prescription. They will then be sent to patients as a pack of pre-filled insoles.

Such insoles are yet available but the researchers plan to test them out soon to see whether they improve the healing process of patients.

Source: Purdue University

License: The text of "3D Printed Insole Speeds Up Healing Process of Diabetic Ulcers" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.