Science is in a relentless pursuit to copy nature. Lightweight yet incredibly strong structures like coral and some plants often defy our ability to replicate them with modern manufacturing.

The layer-by-layer process of 3D printing metal is opening doors to more closely mimic lattice-like structures grown in nature. Take for example the new titanium structure combining innovative geometry and material developed at Australia’s RMIT University that’s 50% stronger than the strongest alloy of similar density used in aerospace applications.

The university says this breakthrough “could change how we make everything from medical implants to aircraft or rocket parts.”

The new titanium structure is called a metamaterial, which means it’s an artificial material with unique properties not observed in nature. The term is a bit misleading because it refers to more than the actual “material”, which was a common titanium alloy (Ti-6Al-4V). It’s a combination of the material and the geometry.

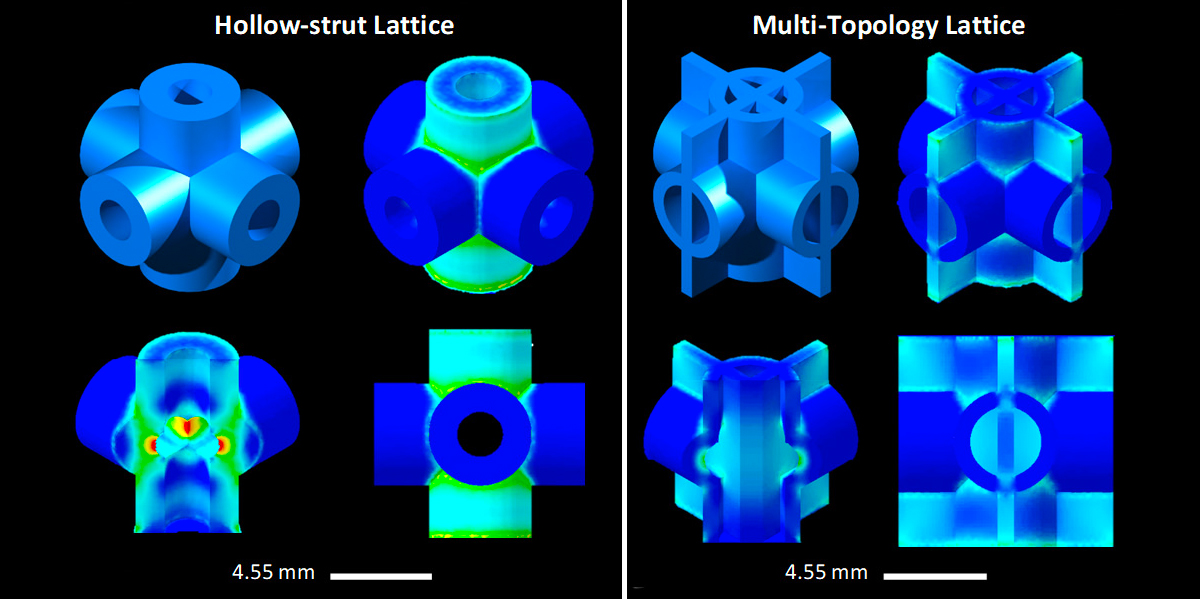

In fact, it’s the shape that researchers are excited about. Lattice structures are widely used in metal 3D printing, but the pinnacle of lightweight lattices is one where the lattice struts themselves are hollow tubes, for even less material use.

RMIT’s Distinguished Professor Ma Qian spent decades trying to replicate these hollow cellular structures in metals, according to the university, and has been frustrated by the common issues of manufacturability and load stress concentrating on the inside areas of the hollow struts, leading to premature failures.

“Ideally, the stress in all complex cellular materials should be evenly spread,” Qian explained on the RMIT blog. “However, for most topologies, it is common for less than half of the material to mainly bear the compressive load, while the larger volume of material is structurally insignificant.”

This is not the case with the new RMIT titanium structure that distributes the stress more evenly, enhancing its strength and structural efficiency.

“We designed a hollow tubular lattice structure that has a thin band running inside it. These two elements together show strength and lightness never before seen together in nature,” says Qian. “By effectively merging two complementary lattice structures to evenly distribute stress, we avoid the weak points where stress normally concentrates.”

The double lattice design also means any cracks are deflected along the structure, further enhancing the toughness, according to the researchers.

Study lead author and RMIT PhD candidate Jordan Noronha says they could make this structure at the scale of several millimeters or several meters in size using different types of printers.

This printability, along with the strength, biocompatibility, corrosion, and heat resistance, make it a promising candidate for many applications from medical devices such as bone implants to aircraft or rocket parts.

This structure is only possible via 3D printing. Researchers used an Nikon SLM Solutions 250HL laser powder bed fusion 3D printer.

“Compared with the strongest available cast magnesium alloy currently used in commercial applications requiring high strength and lightweight, our titanium metamaterial with a comparable density was shown to be much stronger or less susceptible to permanent shape change under compressive loading, not to mention more feasible to manufacture,” Noronha said.

The team plans to further refine the material for maximum efficiency and explore applications in higher-temperature environments.

While currently resistant to temperatures as high as 350 °C, they believe it could be made to withstand temperatures up to 600 °C using more heat-resistant titanium alloys, for applications in aerospace or firefighting drones.

“As the technology develops, it will become more accessible and the printing process will become much faster, enabling a larger audience to implement our high-strength multi-topology metamaterials in their components,” says Noronha. “Importantly, metal 3D printing allows easy net shape fabrication for real applications.”

Access the full research published the journal Advanced Materials.

License: The text of "3D Printed Titanium Breakthrough for Strength Applications" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.