In a relatively short period, 3D printing has shaken up the manufacturing landscape by offering unparalleled production versatility and speed. More and more manufacturers are leveraging additive manufacturing techniques for product design, prototyping, reverse engineering, and a myriad of other applications, enabling them to achieve faster times to market, cut down costs, and reduce the need for large inventories.

The widespread adoption of 3D printing has also fostered a wave of innovation in materials science. Engineers and scientists are now developing advanced materials with unique properties tailored for specific 3D printing applications, further expanding the scope of what can be achieved with additive manufacturing.

In recent years, 3D scanning has emerged as a complementary technology that can further elevate the potential of additive manufacturing. In fact, manufacturers are experiencing tremendous gains by using the two technologies together.

Integrating 3D Scanning to Drive Further Innovation in Additive Manufacturing Workflows

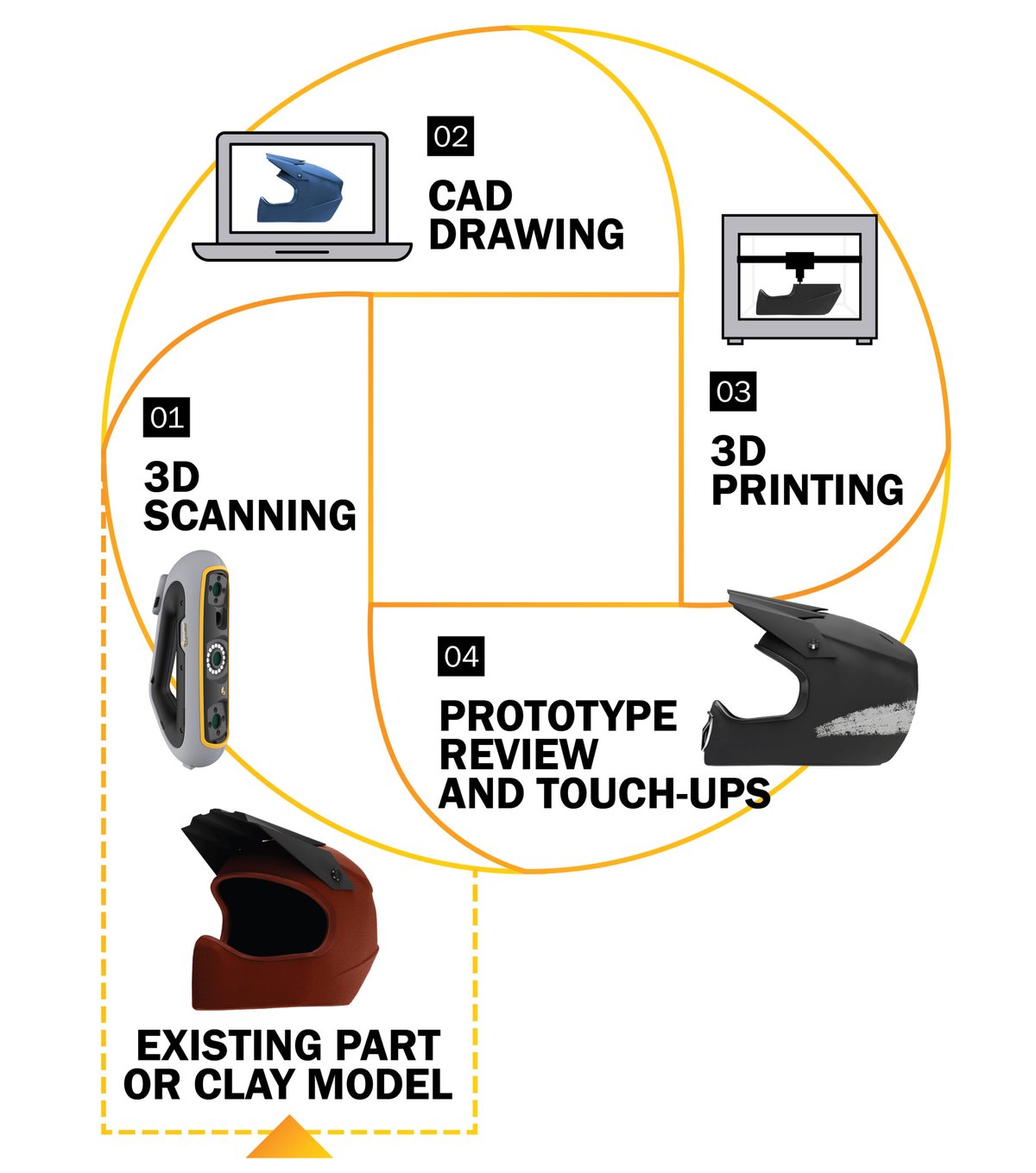

Traditionally, additive manufacturing consisted of initiating a 3D print of an object from a CAD file optimized for design purposes in software, like SolidWorks, Inventor, Solid Edge, and AutoCAD.

However, what happens if the CAD model cannot be found? What if design optimizations are required on an existing part? What if current prototyping processes are too long and costly?

That is where 3D scanning can address many additive manufacturing challenges. Let’s look into the applications in more detail.

Streamlined Design Iterations

The combination of 3D scanning and 3D printing enables rapid design iterations; product development teams can quickly refine and optimize designs. By scanning printed parts and comparing them to the original digital model, industrial designers and engineers can identify areas for improvement and make adjustments accordingly. This iterative process can be repeated until the desired level of performance is achieved, leading to much faster product development cycles.

Digital Twins and Simulation

Digital twins are virtual representations of physical objects or systems that can be used for analysis and simulation. By using 3D scanning to create digital twins of manufactured parts, engineers can simulate the performance of the part under various conditions, leading to better-informed design decisions and more effective products. In addition, these digital twins can be used for predictive maintenance, helping manufacturers minimize downtime and extend the lifespan of their products, as well as quality control to assess part defects and deviations.

Reverse Engineering

In cases where a physical part exists but no digital model is available, 3D scanning can quickly capture the object’s geometry and generate a digital model that can be used for reproduction or modification. 3D scanning allows engineers to analyze and refine existing designs or create new, customized versions of the part using 3D printing. Reverse engineering with 3D scanning and 3D printing has been notoriously popular in the aftermarket and tuning sector and MRO for producing hard-to-source spare parts, for example.

Archiving

Not relegated just to cultural and archaeological purposes, 3D scanners and 3D printers are increasingly being used by manufacturers to improve their organizational memories from a production standpoint. Complete digital 3D models and/or physical 3D-printed models for any mission-critical part or assembly can be safely archived for future use and performance monitoring over time. Consistent archiving can inevitably save production time and costs several years down the line.

In the coming years, manufacturers must embrace these cutting-edge technologies and adapt their workflows accordingly. The synergy between 3D printing and scanning is not merely a technological fling; it is a transformative combination that is reshaping how we design, produce, and maintain the products that shape our world.