Nearly a million tons of fishnets are abandoned in the ocean every year with devastating effects on sea life. This is why global efforts are underway to collect these old nets before they’re ocean waste and recycle the plastic, which both commercializes the recovery efforts and prevents the production of new virgin plastic materials and associated emissions.

Fishnet plastic as a commodity is increasingly sought after by companies looking to boost their sustainability profile and throw their influence behind ocean clean-up. For example, BMW plans to use the old fishing nets in trim parts for its 2025 line of EVs, Samsung repurposes discarded nets into parts for its Galaxy devices, and Mattel released its Barbie Loves the Ocean collection to celebrate its reuse of ocean-bound plastic.

If you 3D print, you can take part in the effort to protect the world’s oceans, one roll of filament at a time. In fact, you have several fishing net filament options to choose from. The newest is a polypropylene-based fishing net filament from Amsterdam-based 3D printing material maker ReFlow, a company specializing in recycled plastics. This material was recently used to 3D print 80 pieces of sustainable street furniture in Milan as part of that city’s Ocean Week, an event to spotlight the issue of ocean pollution. London-based recycled material design firm Supernovas created the furniture in collaboration with One Ocean Foundation.

What’s the Printing Quality of Fishnet Filament?

Cleaning up ocean plastic is something everyone can get behind. However, if your conscience wants to switch to recycled filament but you worry about how your parts will come out, you’re not alone. There’s a wide range of plastic properties among recycled filament, which is one reason ReFlow took two years to develop what it calls the right recipe of polypropylene from recycled nets and glass fiber for its Ocean rPPGF filament and pellets.

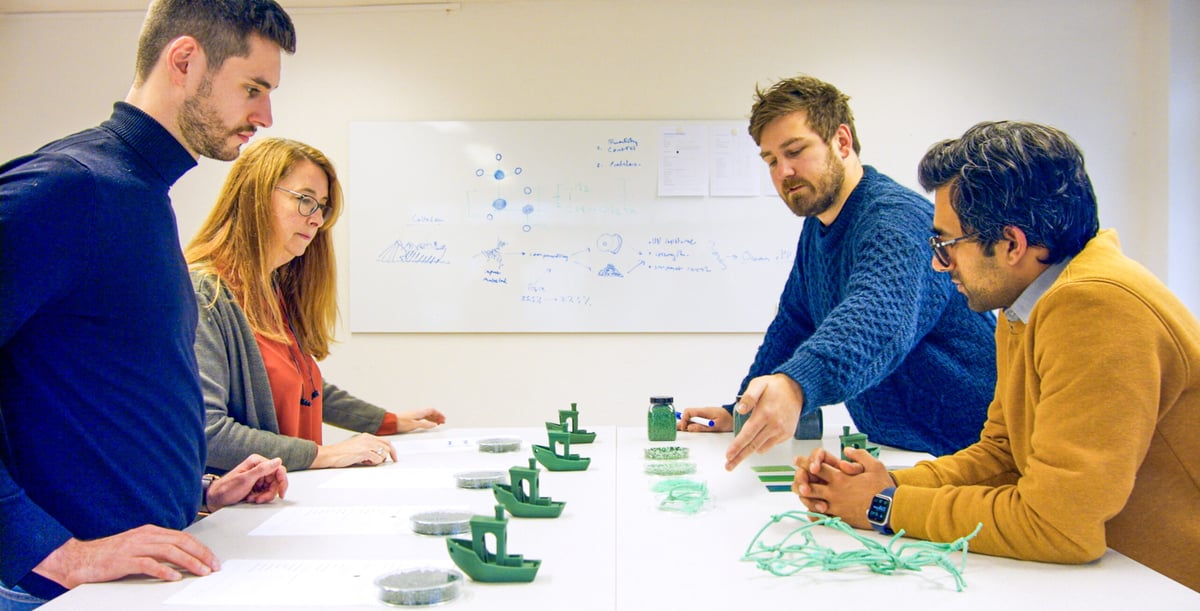

Fishnets and ropes contain different polymer types, and even one rope or fishnet can be made up of multiple polymers. ReFlow approached seven ocean plastic reclaimers to find the optimal quality. Some fishing net resellers were reluctant to sell their plastic to a company that wouldn’t use it as is, but reflow’s research showed the need to reinforce the polypropylene with glass fiber. With about 25% glass fiber added, rPPGF avoids the typical warping you’ll find with most polypropylene filaments, the company says.

“We wanted to make a material that could compete directly with virgin material,” says Ronan Hayes, co-founder of ReFlow. “Removing plastic that’s been degrading for years in the ocean is important, but that plastic doesn’t necessarily make quality fIlament.” And if the recycled filament doesn’t perform, consumers won’t buy it, and it won’t make the intended environmental impact.

“Being sustainable also means you’re creating something that will last for a long time,” notes Hayes.

Ocean rPPGF is aimed at specific applications: outdoor furniture, as well as structural and load-bearing pieces, such as the Milan planters mentioned above. ReFlow says that its filament exhibits excellent UV and chemical resistance, tensile strength, and impact resistance for long-lasting prints that can stand up to the elements. The material comes with a technical data sheet showing tensile strength (35 MPa), tensile modulus (3160 MPa ), elongation at break (3.96%), and other properties professionals need to know to ensure 3D printed part performance.

There are More Options from the Ocean

Ocean rPPGF isn’t your only choice of fishing net plastic-based 3D printing filament. The aptly named Fishy Filaments offers a 100% fishing net nylon (PA6) filament, which it admits may be “a bit salty and have a few bits of seaweed attached.”

The company’s two polymer filaments are both 100% recycled nets with no pigments or other modifiers. Nets are sorted and graded according to color and wear, then processed to maximize their potential. Fishy Filaments says most nets are only used for a few months of commercial fishing, so the material keeps quite a bit of its original properties. Still, to ensure the integrity of the plastic, Fish Filaments uses a third-party lab to certify “that the material we gather isn’t becoming contaminated or chemically altered through its life.”

3D printed lighting fixture company Signify uses Fishy Filaments in a line of lamp shades and pendants called the Coastal Breeze series.

Recycling Parts Made from Recycled Filament

It’s one thing to print with recycled filament but to achieve a closed loop of sustainable material usage, your prints must also be recyclable. Reflow says once it receives back a ton or more 3D prints made from its Ocean rPPGF, it will begin experimenting with how to recycle it back into useable plastic to create a full material loop.

“We’ll investigate the recyclability of the filament to find how many recycle cycles it can go through and retain its material integrity,” says Hayes.

Later this year, ReFlow plans to launch another fishing net-based filament, this time reinforced with a natural fiber.

3D Printing Filament & Pellets from Reclaimed Fishing Nets

- ReFlow Ocean rPPGF: $65 per .8 kg., 1.75 mm or 2.85 mm

- Fishy Filaments: $73 per .75 kg., 1.75 mm

- Naovia PP6r: $50 per .5 kg., 1.75 mm or 2.85 mm

Lead image source: Imaculate layer lines with the rPPGF using the 3MT HDP printer from WASP.

License: The text of "3D Printing Filament From Fishnets Aims to Save the Ocean" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.