With a focus on applications that require high precision and low volume, 3D Systems is launching a new version of its Figure 4 DLP resin 3D printer along with new materials. The company says these developments are targeting specific industries that want to complement or replace injection mold tooling, such as motorsports components, furniture hardware, and electrical connectors.

3D Systems’ Figure 4 was first introduced in 2017 as part of the company’s strategy to create a modular and scalable resin 3D printing platform for industrial production. The name “Figure 4” is a nod to the original stereolithography diagram in the 1986 patent filed by 3D Systems’ co-founder and stereolithography inventor Chuck Hull, which was labeled “Figure 4.”

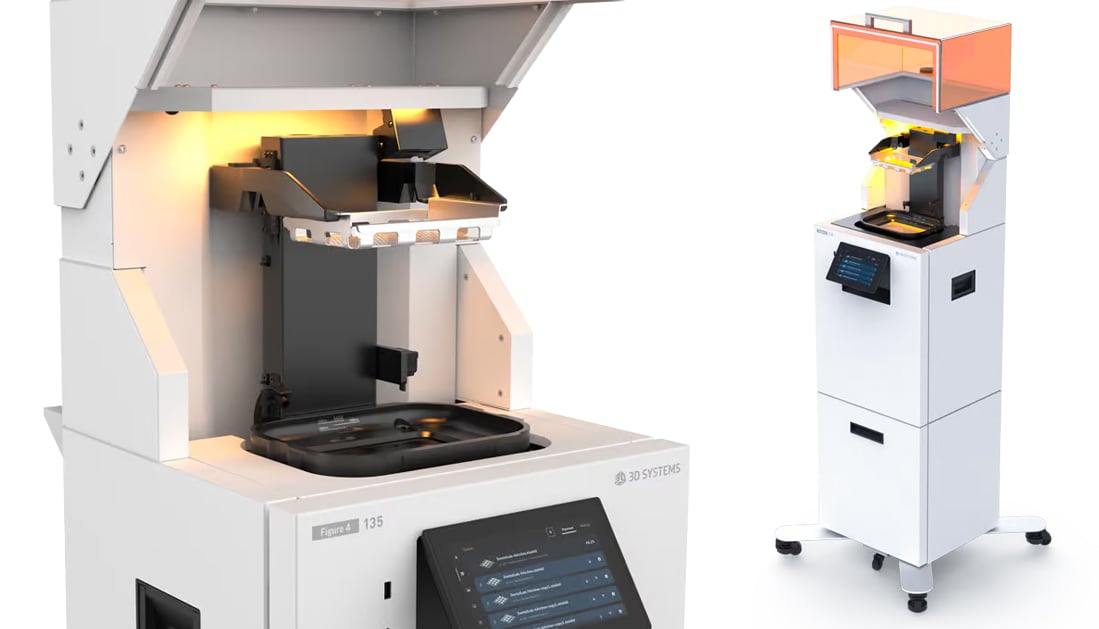

The new Figure 4 135 is the company’s latest addition to the line which includes larger and smaller editions.

The “135” boasts a 136 x 76 x 165 mm build volume, which is slightly larger than the Figure 4 Standalone and the Figure 4 Jewelry (the latter doesn’t appear on the company’s website anymore and may be discontinued).

Print speed is 70 mm/hour for most materials, which is slightly slower than the 100 mm/hour on the Standalone edition. However, the Figure 4 135 features a high 50-micron resolution with a +/- 50 micron accuracy. The minimum layer thickness is just 20 microns.

The Figure 4 135 is compatible with 10 materials out of the gate, including the new Tough 75C FR Black. This flame-retardant material has a UL94 V0 rating that makes it suited for appliance, consumer electronics and automotive applications that require electrical safety.

Also at Rapid + TCT, 3D Systems (booth 3201) is introducing a new module for its Titan Pellet FDMs that optimizes the extrusion flow rate in real time, reducing the opportunity for voids to form. The improved solidity reduces post-processing time in machined printed parts by up to 50%.

You May Also Like:

License: The text of "3D Systems Debuts Its Upgraded Resin DLP Figure 4 at RAPID + TCT 2025" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.