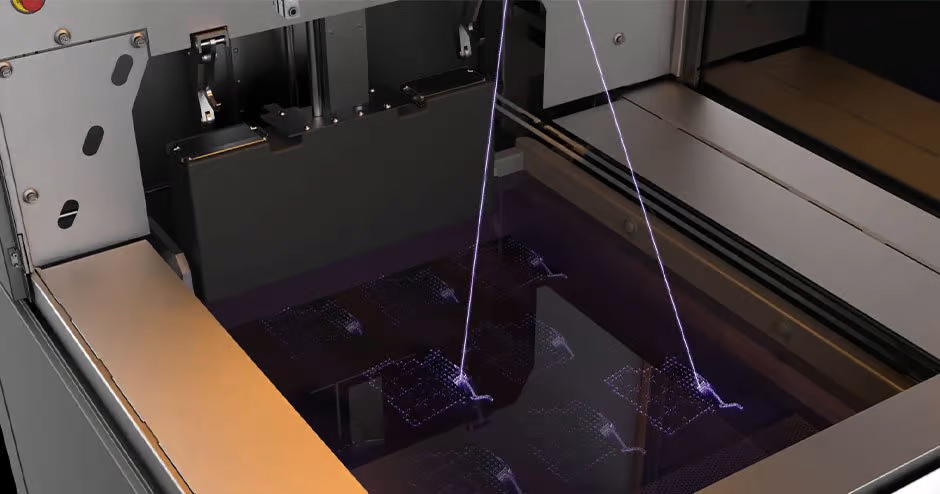

3D Systems’ new resin printer launched this week, and it was worth the wait. The company hasn’t launched major advancements in its stereolithography technology for a while, apparently keeping all the bells and whistles for the new baby: SLA 750 Dual.

What 3D Systems claims to deliver with this release is the promised land of production resin 3D printing: A single platform combining size, speed, accuracy, and resolution for final parts with excellent finish and mechanical quality.

The SLA 550 Dual is 3D Systems’ fastest resin printer to date and features 15% more print volume than its ProX 800 while having a smaller overall footprint. The focus of the machine is to deliver large, production resin parts and batch-part production for industries from transportation and motorsports to aerospace and healthcare.

Let’s take a closer look.

Dual Lasers!

New tech behind this significantly improved printer speed and throughput is 3D Systems’ new and proprietary scanning algorithm called Hyper-Scan. The laser control feature optimizes laser focus, power, and vector motor kinematics.

The system also features a self-calibrating dual-rail recoater designed to improve print process reliability and final part mechanical properties, the company says.

3D Systems’ says the SLA 750 is “the fastest stereolithography solution available” without providing actual speed, so take claim that with a grain of salt.

“I see the launch of this new platform … as an example of how we are executing on a global AM strategy that focuses on our strengths,” says David Leigh, executive vice president & chief technology officer for additive manufacturing at 3D Systems. “I believe we are entering an era where there will be a path of rapid evolution to our innovations. In this light, our multi-purpose SLA platform will become a system that can help scale production applications through built-in functional and throughput enhancements.”

Tech specs

- Technology: Stereolithography (SLA)

- Max part size: 750 x 750 x 550 mm

- Energy source: single or dual 4-watt laser

- Max resolution: 2000 dpi

- Availability: SLA 750 single laser, Q2 2022; SLA 750 Dual, Q4 2022

- Price: $400,000 – $420,000

Not Just a Printer, A Production Platform

Par for the course at 3D Systems, the SLA 750 release is accompanied by a full ecosystem of production-enabling tools, including a new resin, a new curing station, and new workflow software.

3D Systems calls its new all-purpose industrial resin Accura AMX Durable Natural. This resin boasts high mechanical properties, including impact resistance, tear strength, and elongation at break. The company says this material exhibits similar stress and strain toughness performance to standard thermoplastics, and its isotropic mechanical properties ensure superior part strength in any build orientation.

Accura AMX Durable Natural applications range from large, complex mandrel tooling cores to manufacturing aids for large cooling ducts, pipes, and manifolds used in automotive, aerospace, energy, and consumer goods applications. What the “natural” means in the name isn’t clear. In addition to this material, the SLA 750 prints with 14 other 3D Systems resins.

PostCure 1050 for high-volume post-processing

A high throughput printer, naturally requires a larger volume curing machine. The 3D Systems’ PostCure 1050 can cure parts as large as 1,050 x 750 x 600 mm quickly – up to five-times faster than comparable solutions, the company says, due to a consistent 360° light uniformity (no part flipping).

With this much LED light, it’s good to have an automatic detection and alert of light failures, an easy light output calibration routine with a separately configurable UV intensity, and actively cooled LEDs. PostCure 1050 is compatible with all 3D Systems resin printers and suitable for all current and future material innovations, the company says.

Production Workflow Software, Oqton

Late last year, 3D Systems acquired the additive manufacturing workflow software company Oqton and wasted no time integrating the solution into the 3D Systems ecosystem.

The software is designed to automate additive manufacturing production by integrating the workflows of engineering and production. In other words, it connects applications across the product lifecycle – CAD, CAM, 3D printing, simulation, reverse engineering, and inspection – while inserting some AI and machine learning technologies. The goal is to connect technologies and machines across multiple sites, automate, and increase the traceability and visibility of production 3D printing.

Lead image source: 3D Systems SLA 750 Dual

License: The text of "3D Systems’ New High-Speed, Production-Ready Resin Printer" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.