3D printers are used across a large number of industries, but a few are so profitable they demand their own customized 3D printers. Jewelry is one of those markets.

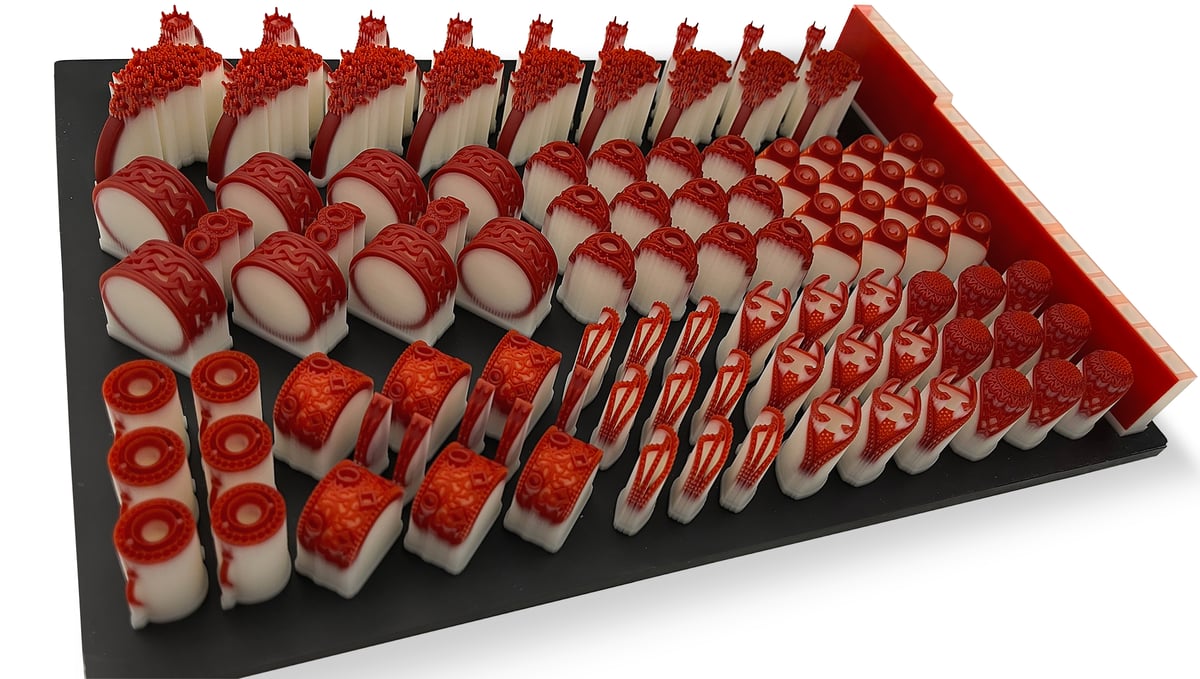

Jewelry designers have adopted wax and castable material 3D printing in droves for its ability to take their designs from CAD file to model in a fraction of the time of hand carving. Large commercial jewelry makers followed suit. With large volume 3D printers, they could do more customizations faster and reach new markets.

Printer maker 3D Systems was a pioneer in jewelry model 3D printing and, today, launched a new, high-volume 3D printer and an advanced wax material aimed at the largest players in the $8B 3D printed jewelry market.

The new MJP 300W uses 3D Systems MultiJet Printing (MJP) technology, which is a type of material jetting, to 3D print highly detailed jewelry patterns at a max speed of 240 cm3 per hour.

The goal is to deliver more patterns faster without sacrificing quality to help jewelry producers keep up with their metal casting workflow.

3D Systems already has four other large wax 3D printing platforms. But with the introduction of the MJP 300W, the company is unveiling two new print modes that give users more flexibility in their production processes.

The QHD (which might stand for quality high-definition, but 3D Systems doesn’t say) mode enables more than 50% improved resolution compared to the older ProJet MJP 2500W Plus, which was just launched in February, and an impressive 9.5-micron layer thickness. “This delivers a premium quality surface finish, allowing designs to be produced with less finishing required,” the company says.

The other mode, UHD, offers twice the print speed of the ProJet MJP 2500W Plus. UHD offers significantly increased throughput and reduces the labor required for finishing and polishing, 3D Systems says. “The availability of four print modes offers improved flexibility in build planning for both day and night shifts to match the level of speed, geometric complexity, and surface quality required by all design styles.”

One quality of life feature that clearly came from users is a light. This new light can be positioned for better visibility into the printer to monitor print job progress.

New 100% Wax Material Has Better Mechanical Properties

Along with the new printer, 3D Systems is launching a new wax model material that’s stronger and less prone to warping and melting. VisiJet Wax Jewel Ruby is the company’s “most advanced material”, it says. Jewel Ruby creates models with better durability that enables manufacturers to test set stones. The more robust models can also resist breaking through normal handling and maintain their dimensional stability through shipping. Ruby has higher thermal stability compared to the recently introduced VisiJet Wax Jewel Red.

Tech Specs & Price

- Technology: Material jetting

- Print volume: 294 x 211 x 144 mm

- Min layer height: 9.5 microns

- Materials: VisiJet Wax Jewel Red, VisiJet M2 Cast

- Price: ~$75,000 – $90,000

License: The text of "3D Systems’ New Wax 3D Printer Brings Faster Mass-Customization to the Jewelry Market" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.