The increased adoption of closed-loop architecture is causing the 3D printing industry to undergo a transformative shift. With it, users are already achieving greater levels of printing success with higher-performing final prints, as they leverage advanced integrated systems such as HeyGears’ UltraCraft Reflex.

Addressing 3D Printing Pain Points

By implementing a closed-loop architecture, HeyGears is able to directly address key challenges and pain points faced by 3D printing users around the world, paving the way for enhanced performance, accuracy, and stability.

In traditional open-loop systems, controlling and maintaining consistent print quality is often difficult. Variations in external factors such as environmental conditions, material properties, and mechanical constraints often result in suboptimal print results. However, recognizing these limitations and turning to closed-loop architecture offers a more reliable printing process through precisely crafted and integrated hardware, systems, and materials.

As the demand for desktop resin 3D printing solutions escalates, HeyGears’ UltraCraft Reflex has emerged as a pioneering force, with an all-encompassing solution that provides stable and reliable performance, placing the actual usage requirements for each final printed part at the center of its intelligent printing strategies.

Success in Resin 3D Printing with Closed-Loop Architecture

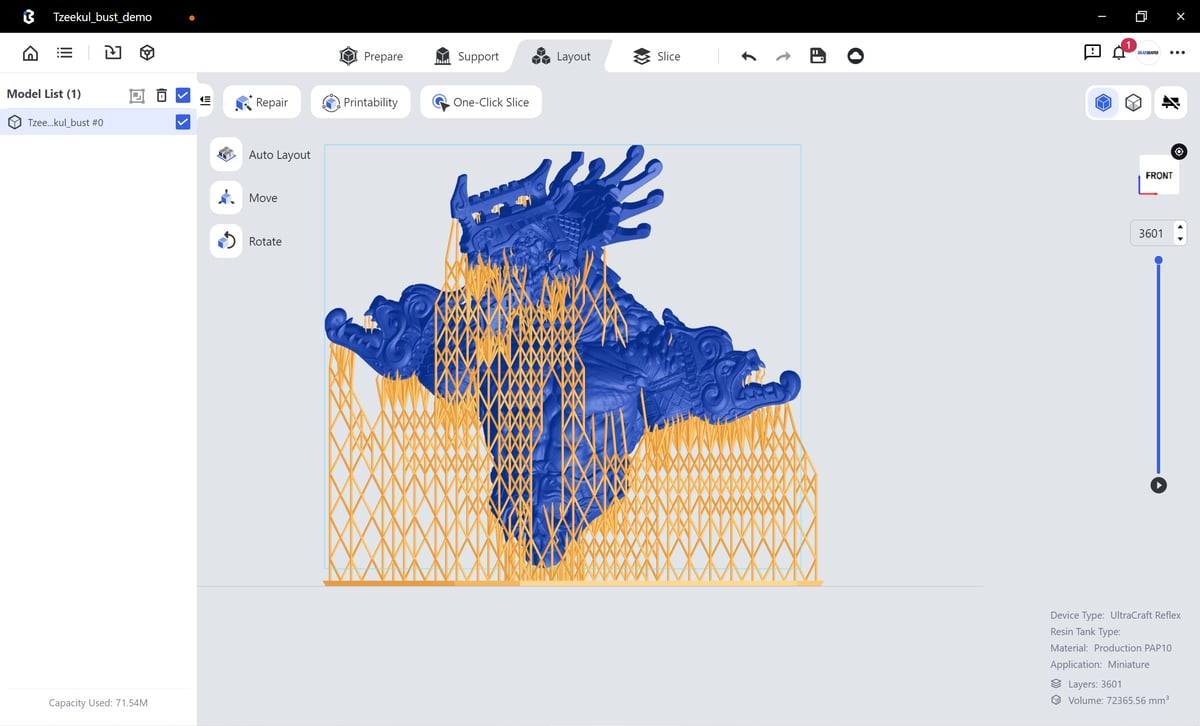

From pre-processing to printing to post-processing, the HeyGears UltraCraft Reflex combo provides a complete solution. It includes the UltraCraft Reflex 3D printer, along with a wash unit and a cure unit. With the help of HeyGears’ Blueprint Studio software and their self-developed resins, this all-in-one package leverages its closed-loop architecture to prepare dedicated printing strategies to ensure consistent and predictable high-quality results.

These strategies play a key role throughout the entire printing process, and are achieved by HeyGears placing a particular focus on high-quality hardware, software development, and automated parameter configuration.

A closed-loop architecture operates within pre-established optimal parameters and hinges on three pivotal elements to achieve high rates of print success: the optimization of printing strategies, a unique high-energy UV light source, and the use of high-performance, tailor-made resins. Let’s take a look at each of these elements.

Three Elements to Optimize Resin 3D Printing

For printing strategies, the UltraCraft Reflex leverages precise settings derived from robust algorithms, which have been refined through numerous iterations and 3D printing tests. This results in parameters to maximize the overall print success and achieve optimal performance, leading to reliable, commercial-grade final printed results.

The UltraCraft Reflex makes use of a precisely tuned light source using “TrueUV” wavelengths. These wavelengths are higher-energy than the more commonly used 405 nm wavelengths, and allow for superior cross-linking and enhanced final properties of finished prints. This means the Reflex is able to offer improved energy absorption by resin photoinitiators. By using HeyGears’ UltraPrint resins, which are tailored to these higher energy wavelengths, users can achieve injection mold-like results with 3D printing.

This brings us to the third element: HeyGears self-developed resins, which are a crucial part of the complete closed-loop system. When aiming for optimal performance and printing results, the choice of resin is extremely important.

By using a resin that is aligned with characteristics of a particular 3D printing light source, users will experience significantly enhanced overall performance for their prints. HeyGears resins, which are designed specifically to be used with the TrueUV wavelengths, ensure greater printing success and maximize the printing potential of the closed-loop architecture, resulting in superior results across a wide range of 3D printing scenarios.

The Benefits of a Closed-Loop System for Resin 3D Printing

Users of the UltraCraft Reflex are poised to reap numerous benefits from its closed-loop system. Because all elements of a closed-loop systems are controlled – and thus are inherently predictable and can be carefully optimized – they offer a notable advantage over open-loop systems. This makes closed-loop systems a reliable choice for achieving optimal results with resin 3D printing.

The Future Possibilities

The ongoing advancements in closed-loop architecture are not just limited to optimizing performance, accuracy, and stability in resin 3D printing. As we look into the future, the predictable systems and processes that a controlled ecosystem enables will provide the opportunity for the development of specially designed 3D printing materials that feature advanced properties – for example, materials with predictable heat resistance or greatly increased flexibility.

HeyGears has Black Friday deals from November 20-30, 2023. To see the latest promotions and learn more about the HeyGears UltraCraft Reflex 3D printer, visit: https://store.heygears.com/