Additec, which made its name in laser directed energy deposition (DED), added a metal laser powder bed fusion (M-LPBF) 3D printer to its lineup last week at Rapid + TCT 2025.

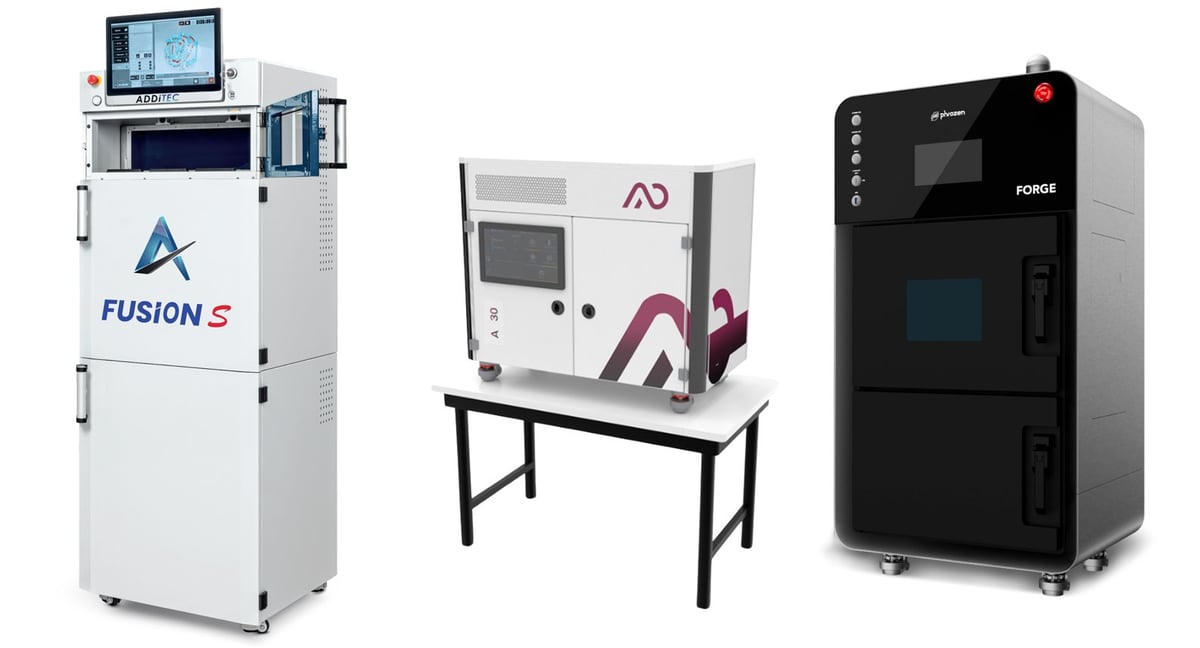

The company launched the Fusion S, a new machine intended for small applications in aerospace, defence, dental, jewelry, energy, and tooling industries.

The Fusion S is compatible with a wide range of metals out of the box, the company says, and works with metal powder cartridges instead of loose powder to limit operator exposure to potentially harmful airborne particles.

“The closed powder circuit ensures more safety at work because the operator doesn’t come into contact with the powder during the entire printing process,” according to Additec. To ensure there’s no contact, Additec is selling the printer and the Fusion cabin material packing and depowdering station as a pair for $159,000, additional Fusion S printers are $129,000.

The Fusion S has a 200-watt, 1070 nm laser with a 50-micron spot size for layer thicknesses from 10 to 50 microns. Its max scan speed is 5 m/s.

The company’s new Fusion Builder software manages your project creation. Materials include, nickel-based alloys, cobalt-chrome alloys, precious metals, and reactive metals.

Also launching recently is the Forge, a metal laser powder bed fusion machine from Phrozen aimed at dental appliances, and Additive Plus’ compact AO Metal line consisting of three metal laser powder bed fusion options.

The Additive Plus A30 AO is a desktop size metal LPBF machine, while the A50 (Ø50 х 100 mm) and A100 (Ø100 х 100 mm) are benchtop versions with optional dual laser configurations. The small A30 can process nickel-based alloys, stainless steels, ferromagnetic materials, titaniums, Inconels, cobalt chromes, alumiums, tungsten, and magnesium alloys.

As market giants, EOS, Nikon SLM, HBD, Farsoon, and BLT, dominate the larger-scale metal 3D printing space with ever larger and more powerful options, the entry space, where manufacturers are evaluating the feasibility of metal 3D printing for their operations is ripe for start-ups and innovators who are lowering the price and complexity of metal powder bed fusion 3D printing.

Information on Phrozen’s Forge is scarce since the company has yet to officially launch the machine. The official launch is expected around Q3 or Q4 2025 Pricing from Chinese companies are, likewise, unavailable as they navigate the current global tariff situation.

You May Also Like:

License: The text of "Additec’s New Fusion S Joins a Surge in Small, Affordable Metal 3D Printer Launches" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.