Materialise, the Belgian company headquartered in Leuven, is one of the longest-standing, most reputable, and innovative companies in the additive manufacturing sector. Founded in 1990 by Wilfried Vancraen and Hilde Ingelaere, Materialise offers a comprehensive range of 3D printing software and services, empowering industries such as healthcare, automotive, aerospace, and consumer goods to develop innovative applications.

Having previously transformed Materialise Medical since 2016 into the company’s most profitable segment, Brigitte de Vet-Veithen now leads the global 3D printing pioneer through an era of significant market shifts and technological advancements. With over 30 years of experience in healthcare and technology, she stepped into the role of CEO at Materialise on January 1, 2024. With over 2,000 employees in 19 countries, the company, listed on NASDAQ since 2014, continues to push boundaries in personalized healthcare and industrial manufacturing.

In this exclusive interview, held at AM Forum Berlin, de Vet-Veithen shares insights into her journey, the evolution of Materialise under her leadership, and the challenges and opportunities facing the additive manufacturing industry today.

All3DP: Do you remember the first 3D printed object you encountered?

Brigitte de Vet-Weithen: Yes, I do! Coming from Johnson and Johnson’s medical field, I had no deeper knowledge of the additive manufacturing industry. I wasn’t even particularly drawn to the field. However, during a visit to Materialise, my perspective changed completely.

The turning point was seeing a personalized hip implant for a patient who spent three years in a wheelchair. This individual had endured ten years of pain and numerous surgeries, which left the hip with virtually no bone stock. Materialise provided him with a 3D printed personalized hip implant, and just one week after surgery, he was walking again. That captivated me. I immediately recognized the transformative potential of the technology and how it could profoundly improve lives.

As an engineer, I was also amazed by the technical ingenuity behind the implant. Its design incorporated intricate structures to ensure it adhered to the bone and stimulated bone growth. Witnessing this combination of engineering excellence and life-changing impact convinced me that this was where I wanted to be. I was sold immediately.

After you joined Materialise, your medical division became the company’s most profitable segment, and since January 2024, you lead the company as CEO. What have you changed at Materialise since then?

A few things, I suppose. First, you always bring your authentic self to the table – your own style and way of doing things. Each approach to leadership is unique. That naturally sets us apart from others who lead companies. I hope to bring a fresh perspective to specific situations, offering different viewpoints and contributing to better decision-making. Creating an impact drives me, and I strive to make a difference every day.

Also, the market around us has changed significantly. At this point, we are in a particularly interesting period. Nothing is certain anymore.

From your perspective, what are the challenges of the AM industry?

Assumptions we rely on are no longer true, making certainty a thing of the past. For instance, developments in China and shifts in U.S. policies, such as the tariffs imposed by the Trump administration, dramatically alter global trade dynamics. These changes have reshaped the world’s economic landscape in unforeseen ways.

"Assumptions we rely on are no longer true, making certainty a thing of the past." — Brigitte de Vet-Veithen

Additionally, the 3D printing industry has faced its own challenges. After a difficult year, the sector continues to navigate these complexities, highlighting the need for adaptability in this evolving environment.

So the market around us is changing, and we, as Materialise, also need to change. This shift isn’t just about me changing my perspective but about adopting new ways of viewing the market as a company. As an industry, and at Materialise, we need to focus on more than just innovative technology. While the technology is essential, its true power lies in the value it creates. Our priority should be driving meaningful applications that maximize the impact of what our technology can achieve.

Can you give an example of these meaningful applications?

Take the hip patient I mentioned earlier. Clinical evidence shows that 27% of patients with standard implants require revision surgeries. This percentage increases with each subsequent intervention. In contrast, personalized implants backed by clinical evidence show only a 3% revision rate. Out of 100 patients, 24 who would have otherwise needed a second surgery will no longer require that reintervention, resulting in significant savings for the healthcare system and making a profound difference in the lives of patients and their families. This highlights the importance of focusing on the value we create and effectively communicating that impact – something we must prioritize in this evolving market.

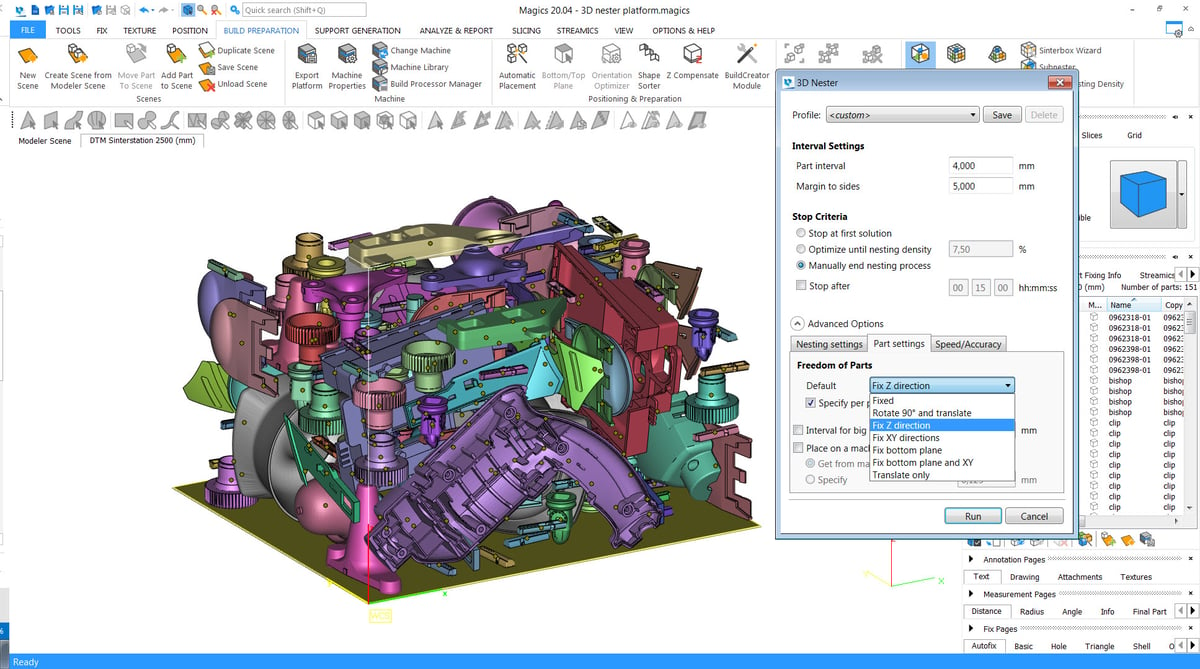

The second key shift is accelerating the transition from prototyping to end-use products. We have discussed this in the industry for years. We are at a critical point where it must become a reality. And Materialise can play a major role in driving this change. For example, our software can be instrumental in enabling cost-efficient, high-quality production of end-use parts. It can significantly lower costs and improve reliability by reducing manual steps, avoiding failures through smarter build preparation, and automating processes like support generation.

Back to your question: there’s a much stronger focus on the factors that will drive broader adoption of 3D printing for end-use parts. This shift is central to how Materialise adapts to meet this changing market’s challenges.

Do you see technologies or materials as game changers, or is AM hardware the main driver?

When it comes to materials, there’s still a lot of progress to be made. The range of materials available for additive manufacturing is limited, restricting certain possibilities. But I wouldn’t go as far as to say materials are a limitation for the industry. Why? Because even with the choice of materials we currently have, there’s tremendous untapped potential. Yes, we need new materials. However, we also need to maximize the possibilities of existing ones. We can achieve this through better software and by optimizing how technologies work together.

As I’ve mentioned before, I’m a strong advocate for collaboration in this industry. To drive the adoption of end-use products, it’s not just about software, printers, or materials individually – it’s about the synergy between all these elements. Software plays an important role, but real progress will come from ensuring that all components – materials, technologies, and processes – work seamlessly together. Collaboration is key to unlocking the full potential of additive manufacturing.

Speaking of collaborations: You co-initiated the Leading Minds Consortium. It aims to increase awareness of 3D printing’s capabilities, eliminate adoption barriers, and create a common language framework in industrial additive manufacturing. How is it coming along?

The Leading Minds Consortium has progressed well since its launch at Formnext 2024. We’ve set clear KPIs for this year and are steadily working toward them, engaging the founding members and aiming to bring others along on this journey. It’s a long-term initiative, which is crucial in today’s uncertain economic climate.

So we’re making steps. It’s going to be a journey, but we knew that. In challenging times, there’s often a temptation to focus on short-term goals, but we must resist that. The long-term potential of additive manufacturing is immense, and it’s vital to keep investing in the future. The Leading Minds consortium is designed to drive this forward, emphasizing collaboration and innovation.

By Formnext later this year, we’ll evaluate whether we’ve achieved our KPIs. Expanding awareness and growing the industry remain key priorities, and initiatives like Leading Minds play an important role in shaping the future of 3D printing.

So, you already said that you’re highly interested in partnerships. Is building alliances a female strategy approach in a predominantly male industry?

I don’t believe this is a gender-specific approach, and here’s why. Collaboration has always been part of Materialise’s DNA, thanks to our founder – a man – who instilled this ethos in the company. From the beginning, Materialise has worked with numerous partners across the industry, fostering openness and cooperation as a core principle.

While some might stereotype women as more inclined toward collaboration, I wouldn’t generalize. In our case, collaboration is simply fundamental to who we are as a company. For example, our software enables competitors to enhance their capabilities in the medical sector, reflecting our commitment to creating a healthier world. By encouraging broad access and working with everyone, we aim to touch more lives and leave a lasting legacy.

Ultimately, collaboration isn’t about gender. It’s about leveraging partnerships to drive impact and achieve shared goals. This approach aligns with our mission to create meaningful change and improve the world.

Materialise has three strong pillars: the software, the printing service, and consultancy. Which part is currently the most important to you in 2025 and beyond?

We’ve always believed that having all activities benefits our customers. Our software team learns from what the manufacturing team struggles with, and they build this into software that will benefit our customers. And the other way around, our manufacturing team leverages the software engineers to handle specific problems. It’s the synergy, and none is more important than others.

If we step back and consider global developments, two scenarios emerge. First, uncertainty surrounding the U.S. administration and China’s response could lead to hesitancy in capital expenditure decisions, benefiting our manufacturing unit as companies outsource their 3D printing activities. In the second scenario, tariffs and protectionist policies might drive localization or regionalization of production hubs, creating significant opportunities for additive manufacturing to address these challenges. In this case, investments in capital expenditure would occur, and our software would play a key role in enabling localized production. Both scenarios are equally important to us, though the outcome remains uncertain.

If you could wish for one thing in the industry, what would it be?

A bit more long-term thinking. I understand it’s not always easy. Our industry’s potential is immense, but it’s a slow revolution. We’ve always acknowledged that the adoption of additive manufacturing will take time. In the past, we’ve seen how short-term hype can lead to unrealistic expectations, and we must avoid repeating that mistake. Instead, we must stay committed to the long-term vision and continue investing in the future as an industry.

In the past, we've seen how short-term hype can lead to unrealistic expectations, and we must avoid repeating that mistake. — Brigitte de Vet-Veithen

I fully recognize that this approach can be challenging for some of our colleagues, especially in uncertain times. However, if we truly want to unlock the full potential of additive manufacturing, long-term thinking and sustained effort are essential. It’s about staying focused on the bigger picture and believing in the transformative impact this industry can achieve over time.

You May Also Like:

License: The text of "Additive Manufacturing in the Age of Uncertainty: Materialise CEO on Adapting to Change" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.