Since its founding in 1989 by Dr. Hans Langer, Munich-based company EOS developed into one of the leading manufacturers of industrial 3D printers for plastic and metal printing. In addition to hardware, the company also offers services, materials research, software, and training. Recently, EOS reached a milestone by installing its 5,000th industrial 3D printer: the ultra-fast 4-laser flagship EOS M 400-4 will produce metal parts at Keselowski Advanced Manufacturing (KAM) in Statesville, North Carolina.

All3DP caught up with CEO Marie Niehaus-Langer at the DLD conference in Munich to discuss market growth, trends, trade, and acquisitions. The following conversation is a translation from German. You can read the original here.

Unlike most of its competitors, EOS is an owner-managed company. Five years ago, you took over the business from your father, Dr. Hans Langer. What has changed at EOS since then?

Marie Niehaus-Langer: Ten to fifteen years ago, when 3D printing was booming, many large and renowned companies entered the market. Their investments came when the technology was still maturing, but the economy became unstable. As a result, for many, the market growth they had hoped for did not materialize at the desired intensity. Also, the coronavirus pandemic posed significant challenges for the entire industry worldwide.

At EOS, we made good use of the time. We worked on our products and our competitiveness, which got increasingly challenged. We are highly focused on working with our customers in established and certified markets and are also involved in consumer-related areas.

We continue to focus on innovation through research and development in plastics and metals. We have launched new products and materials onto the market and increased productivity with new machines. In addition to new hardware, it is, above all, the Smart Fusion software for controlling our metal machines that increases productivity and significantly reduces material consumption in the interests of sustainability.

What trends do you see for the near future?

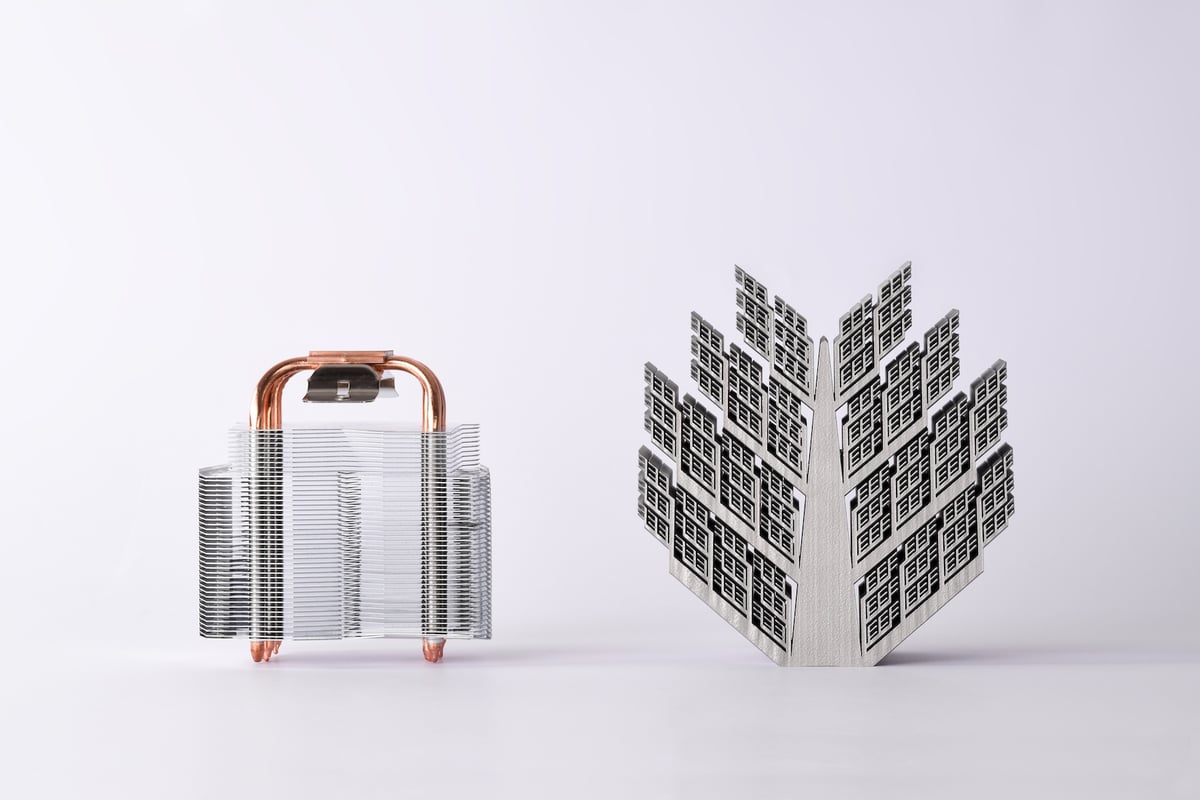

3D printed heat exchangers and everything to do with energy efficiency are currently trending. However, we can also help with the general industrialization of technology. The day’s order remains to offer large production capacities with many machines. Our sales manager jokingly says that we live in a “boring time.” Now, it’s all about industrialization, reproducibility, consistency, and technology reliability.

We also want to reduce the total cost of ownership even further, i.e., the total investment for our customers, as Chinese manufacturers, in particular, are tempting customers with low prices. On the materials side, we are driving forward necessary innovations to identify further applications.

We are seeing strong growth in the defense sector, with the US, in particular, investing a great deal in it. Of course, I have a personal opinion on this topic, but I also see a great need to protect our democratic values. Nevertheless, there is potential to position additive manufacturing more strongly in Europe and to develop it further. The Americans are clever at using defense funding to mature highly innovative technologies. I see a great opportunity here for Europe, too.

You have expanded your presence in the US and are represented by EOS North America in Texas and Michigan. In addition, the EOS M 290 is now built in Texas. Do you want to accelerate growth in the US further?

Due to the political premise of the US to produce heavily at home, we are preparing to secure our metal business, 70% of which already takes place in the US. We want to minimize risks and produce more in the US. This does not mean we are now moving our headquarters to the US. However, we will become more involved in regional markets. We see this less as a challenge and more as an opportunity to strengthen our US business.

Many industrial printer manufacturers have been in rough waters for years. In addition, EOS appears to be a stable “tanker” in a volatile environment. What do you do differently from your competitors?

A family business or a 100% owner-managed company can afford to think medium-term in times of crisis. Anyone who is listed on the stock exchange or financed by financial companies, on the other hand, has to focus on the shorter term. This does not mean that we have to put our house in order and adjust cost structures from time to time, especially after the “golden years” of 2015 to 2017, which were too good to be true. We are doing this with a strong awareness and commitment from our shareholder family. This helps us to make and adapt the key strategic decisions.

How do you assess the current environment for mergers and acquisitions in the AM sector? Do you not see anything worth taking over?

When we talk about the big players, there is no organization we have not examined to see whether it makes sense to consolidate. But in the end, it’s all about whether the portfolio and the markets fit together and how much acceleration you can achieve. If I am too busy reorganizing my portfolio after an acquisition, it doesn’t help anyone.

We prefer to focus on strategic partnerships, such as the supply chain. We believe in strong and trusting strategic partnerships. Through AM Ventures, we also work with early-stage start-ups to realize collaborations with EOS or companies within the Group.

License: The text of "After Selling 5,000 3D printers, EOS’ Marie Niehaus-Langer on What’s Next" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.