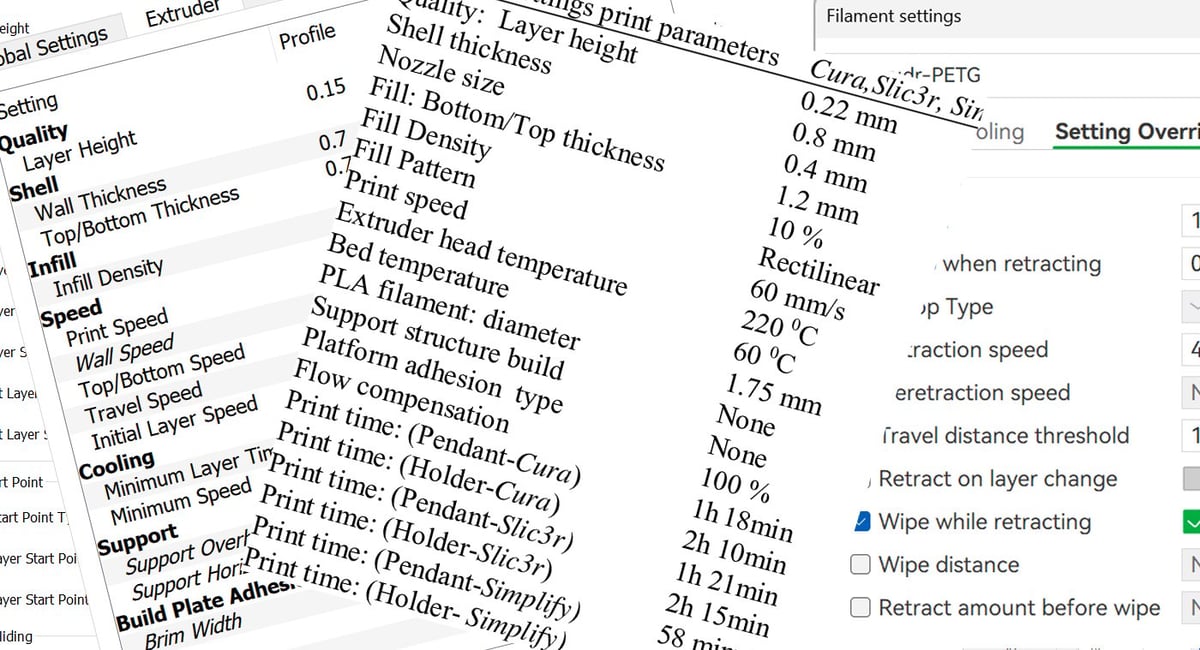

Part of the initial appeal of 3D printing as a hobby was all the tinkering you could do with the dozens of settings, both in the software and on the hardware, that affected your final printed part. Later, people, especially professionals, wanted to push a button and get a part without worrying about the fine details of layer height, infill, speed, temperature, flow rate, and the long menu of adjustable print parameters.

Today, we may be on the cusp of the next step: artificial intelligence that 3D prints, then learns, then 3D prints better.

Myriad research projects are underway, but one, recently published in the journal Advanced Materials Technologies, shows how an algorithm learned to identify the best version of a 3D printed anatomical model by printing out 60 continually improved versions.

This Washington State University study could lead to more seamless use of 3D printing for complex designs. But, what sets this study apart from other AI 3D printing applications is that it can balance certain parameters for an optimal print, instead of focusing on fixing one aspect, such as geometry, defects, or speed.

“Despite the rapid emergence of novel applications in 3D printing, the process of selecting appropriate parameters for 3D printing remains a labor-intensive and inefficient process,” the report notes.

The trial-and-error method of print parameters development is wasteful, while, on the computer-aided design side, assessing various 3D printing design configurations typically involves complex, often expensive, simulation software and calculations. Then, to prove the final 3D printed parts’ mechanical properties, including porosity and yield strength, there can be a long lab-testing verification process. Plus, ideal settings vary depending on the desired output, whether it is a high-detail prototype or a final engine part.

The new algorithm, the Washington State University researchers say, has the potential to take into account multiple aspects of part development and production.

“Existing methods for optimizing 3D printing parameters … often concentrate on optimizing the printing’s overall performance or focus on one specific aspect of printing quality,” the report notes. “These methods primarily rely on experimental data from previous 3D printing configurations tend to overlook variations in the print quality due to differences in printing approaches, material types, and object geometries by focusing on just one of these aspects.”

For example, the researchers note that data from the 3D printing configurations for a cubic cannot be readily applied to 3D printing a spherical because of the significant differences in printing parameter settings. Consequently, there is a need for a general-purpose algorithm capable of identifying optimal 3D printing settings to achieve the best possible printed object quality, regardless of the printing type, material, or shape in use.

Current applications of machine learning to 3D printing employ a single-objective optimization algorithm for individual attributes, such as geometry or porosity. For instance, a set of printing inputs to optimize speed will compromise geometry since each property indirectly affects the other.

The Washington State University study, on the other hand, uses AI to consider multiple input and output criteria for optimizing the 3D printing process. By focusing on a type of machine learning called Bayesian Optimization (BO), the researchers developed a method that enabled the visualization of trade-offs between each set of printing inputs in terms of the output objectives. The result was improved values across all the designated output areas as iterations increased.

Although the study’s objective was to determine the optimal configuration specifically for presurgical organ models, the researchers say the algorithm is broadly generalizable, “capable of adapting to various materials and achieving results across other disciplines without extensive modifications to the core algorithm.”

The development of a general-purpose machine learning algorithm capable of quickly identifying optimal 3D printing settings will no doubt save manufacturing time and cost, reduce labor intensity, and improve the quality of 3D printed objects.

Of course, we’re not quite there yet, but once realized, the effect on the additive manufacturing industry likely will be transformative.

_____________________________

Never Miss Any News:

License: The text of "AI Algorithms Set to Replace All Those 3D Printer Settings" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.