There’s something to be said for being first. Of course, in the Anycubic Kobra 3 Combo’s case, we don’t actually mean first; we mean second – but first to release a true answer to Bambu Lab’s low-cost multicolor AMS 3D printing systems. But it seems that by racing for an answer to the popular multi-material systems, Anycubic has gone the route of “launch fast, patch later”.

Just a few months from its launch some design changes have happened to the Kobra 3 already, with adjustments to the filament pathing against blockages being one noteworthy example. Complimentary replacement hot-ends is another, following reports of leaky units.

Anycubic is in the process of launching a new slicer, too. Based on Orca Slicer, the new slicer adds functionality missing from the company’s other slicer for the printer. It’s to give users more choice, a company rep told us. Reading between the lines – it looks like it was easier for them to clone and adapt another slicer than it was to develop its current slicer with the necessary features. Such is the whip-pan skittishness of the Kobra 3 Combo.

At its heart, there’s a 3D printer here that can achieve decent multicolor prints, and for a combined price of $379 right now, maybe that’s enough. From our experience and what we’ve observed, it seems to be a roll of the dice as to whether that’s the experience you’ll get.

What’s the Kobra 3 Combo actually like?

The Kobra 3 Combo is a single-nozzle multicolor 3D printing system that goes beyond Bambu Lab’s similarly-priced A1 Combo, with active filament drying as one core perk over its steak-grade-named competitor. As print qualities generally plateau higher and higher, features like drying, print success, and setup mitigation features stand out more. The Kobra 3 Combo has enough to feel like a modern printer.

If you’re lucky enough to get one that just works, then you have a competent, capable, multicolor printing system that churns out clean multicolor prints in a cheerfully quick fashion. In a handful of tests alongside the Bambu Lab A1 Combo, we found the Kobra 3’s default values marginally faster, although the print quality was not quite as good, particularly at the interface between colors. As ever, the print quality is tied is some part to your slicer, and between Anycubic’s two slicers, you can get different print results on prints using the same default settings.

It’s your typical modern 3D printer experience. The printer self-calibrates on the first boot and offers remote printing via slicing software and an app.

Several months on from the printer’s launch, crucial components of its ecosystem remain absent: namely, the 8-filament print head adaptor that will let you pair a couple of ACE Pros with the printer, plus a wider rollout of RFID circuits in the company’s filament. Anycubic tells us that, currently, only its PLA can be read by the ACE Pro, but that more are coming. Likewise, the 8-filament adapter is due to launch later this year.

As is typical of single-nozzle multicolor/multi-material systems, TPU is not officially supported as a printable material. That means you’re limited to printing with the likes of PLA, PETG, and materials of similar printing characteristics when combining materials in a print.

At a Glance

- Build volume: 250 x 250 x 260 mm

- Dimensions: Kobra 3, 453 x 505 x 483 mm; ACE Pro, 366 x 283 x 235 mm

- Weight: Kobra 3, 9.2 kg; ACE Pro, 4.6 kg

- Max. temp hot end: 300 °C

- Max. temp bed: 110 °C

- Other: Fully automatic bed leveling, Wi-Fi connectivity with cloud functionality, companion app, continuous printing (ACE Pro autoload)

Who Is The Kobra 3 Combo For?

The staunchly anti-Bambu Lab crowd? Or perhaps Anycubic superfans?

Dislodging Bambu Lab as the go-to for low-cost multicolor 3D printing is no small task – the bar has been set rather high. For Anycubic to stand out here, there needs to be a USP. Fortunately, in the filament dryer, there is. Anycubic’s ACE Pro gets a leg up on the AMS Lite, Bambu Lab’s near-equivalently priced autoloader, with the ability to cycle heat for up to 24 hours at the four spools loaded within. We can see a couple of situations where this really shines: for users in humid regions of the world and when you use the station simply as an autoloader.

Saddling up with your favorite filaments but having no imminent plan to use them means you really can forget about it until the day you need it – no loading or unloading required. The likelihood of the material being in good printable quality is higher than if it had sat out, exposed to the air on a shelf or something.

Color printing is, of course, king with the Kobra 3 Combo. Anycubic has gone to great lengths to show this off with its partnership with the Pantone Institute and the four special colors of PLA that the Kobra 3 Combo launched alongside. Curiously, you don’t really see many examples of these four mixed in a print; individually beautiful as they are, they’re nauseatingly uncomplimentary colors. A HueForge collaboration or something similar wouldn’t have gone amiss here to truly show off the system’s color-printing chops. There is a 3D photo generation tool tucked away in the slicer that nods in this direction, going as far as to offer color filter themes based on the Pantone colors, which is absent entirely in the Next slicer. Oh well.

Another unique factor that could work in the Kobra 3 Combo’s favor is the pairing of two ACE Pro units to offer 8-filament printing. To date, Anycubic has yet to release the 8-filament hub necessary for this to happen. We’ve been told this will launch in late 2024, alongside a firmware update to accommodate the use of two ACE Pro units. How this will look in practice remains to be seen – the design of the ACE Pro doesn’t appear to lend itself to a two-device setup, with Anycubic strongly recommending you place the ACE Pro to the Kobra 3’s left side, while a lot of the space behind the filament unit is taken up by filament guide tubes and the buffer.

Purge-atory

Being a single-nozzle multicolor printer comes with the drawback of filament purging and nozzle priming between color changes. This is a universal downside of these systems, afflicting Bambu Lab’s AMS devices, and Prusa Research’s MMU, too.

There are usually things you can do to adjust the system’s behavior when purging, such as purging to infill or changing the amount of material purged between specific filaments. At launch, Anycubic’s Anycubic Slicer did not offer any such tools. Only with the launch of Anycubic Slicer Next, currently in beta, has Anycubic really begun to catch up in this regard.

A representative from the company tells us that both slicers will continue to be offered. The original Anycubic Slicer is much tidier in presentation and the most “polished” experience, particularly when remotely connecting to your printer. Next slicer has deeper functionality and offers more to the power user (it’s based on Orca Slicer, rather than a heavily modified old version of PrusaSlicer, as with the original) in addition to more generally useful features like multi-plate setup and inbuilt calibration models. It also produces cleaner multicolor prints, seemingly benefitting from more recent under-the-hood improvements from its newer source slicer.

The ACE Pro unit, on the whole, lives up to its promise. It’s a sealable box that can heat up and cycle said heat around the filament to dry it. You can crank it up to 55°C and run the heating cycle for 24 hours should you so wish, though there are material presets, taking the guesswork out of things for you. As you should reasonably expect, it’s a bit noisy. The ACE Pro’s fans continue to run even when not running a drying cycle.

Loading filament is as simple as feeding the end of your filament into one of the four numbered holes. The system positions the relevant idler barrel to advance the filament, and whisks it away to park ready for use near the print head.

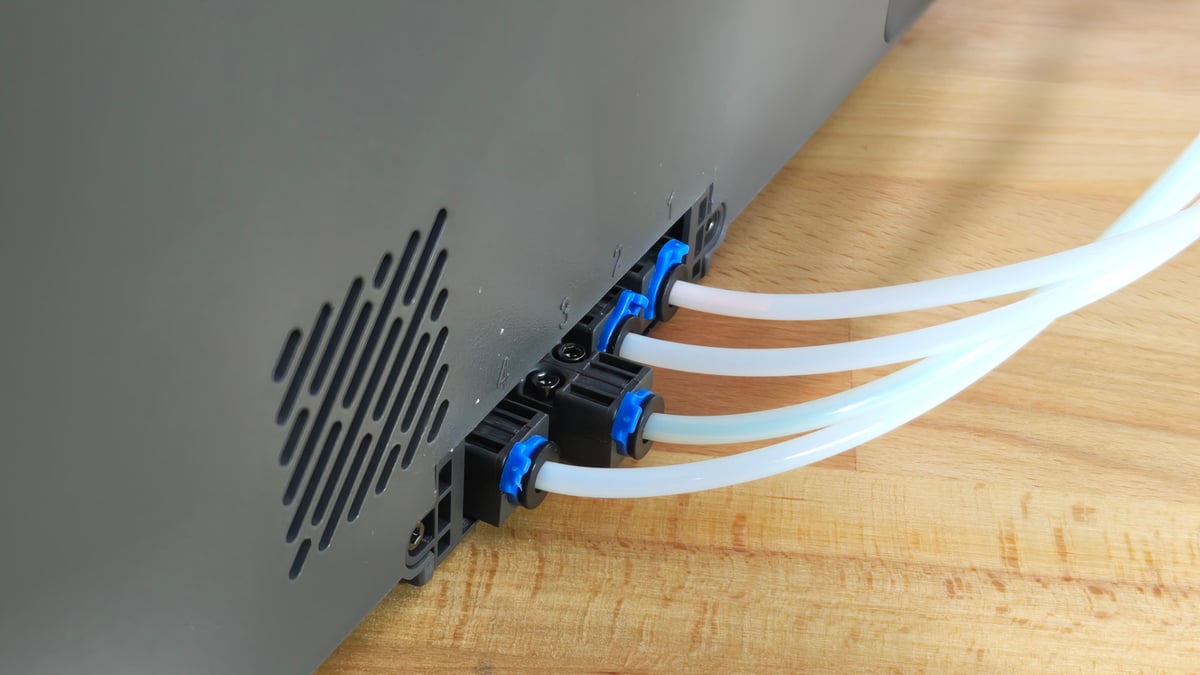

Inside, the ACE Pro uses two barrel-style selectors to grab and feed one filament from each pair. A filament buffer on the rear of the ACE Pro provides slack in the filament for the printer to extrude smoothly, and while it generally works, we did have to dismantle it once to clear a blockage it had created for itself.

When it works, the quality can be fine, offering terrific layer consistency, and in many cases an impressive level of optical quality to the prints. Unfortunately, we could never go more than a couple of prints without the printer failing to load the material, tripping a clog error, failing to implement its bed mesh, or some other unspecific issue impacting print quality.

Throughout the course of our testing, Anycubic did patch a bug that caused frequent clog errors, so kudos to them for the continued attention to patching the printer. Filament loading and leveling issues continue to trouble our unit. Forum posts appear to suggest we’re not alone.

Should You Buy One?

When it’s printing as intended, the Kobra 3 Combo is actually pretty fantastic. For even less money than Bambu Lab’s already scandalously cheap A1 Combo, this system creates clean multicolor prints in a sharpish fashion. On top of that, the ACE Pro unit offers environmental protection for your filament, keeping your materials in printable condition better, for longer.

Its roughness is the biggest factor against it right now, though, with a seemingly large margin between units that function reliably as intended and those that will trip up if you so much as sneeze in their direction.

If you’re comfortable with what seems to be a higher chance of having to file a warranty claim, plus its evolving nature as bug fixes and slicer changes roll out, then the Kobra 3 Combo seems a decent value printer to roll with. From our perspective, though – it is a roll of the dice.

Other new releases:

License: The text of "Anycubic Kobra 3 Combo Hands-On: It’s Great! (When It Works)" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.

Stay Informed, Save Big, Make More

Stay Informed, Save Big, Make More