3D printing by way of vat polymerization has been around for quite some time. Stereolithography (SLA) was the first patented additive manufacturing process back in the 80s. Since then, many sister technologies have seen the light of day, including masked stereolithography (MSLA). It wouldn’t be a stretch to say MSLA is the key tech that allows us to enjoy a large number of budget desktop machines today.

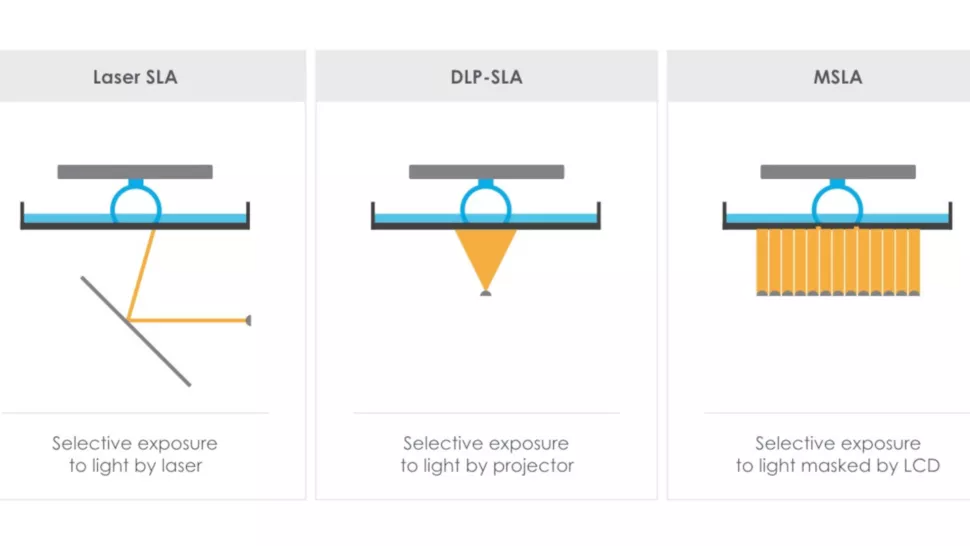

Another process of vat polymerization is digital light processing (DLP.) Their common ground: All use photosensitive resin and ultraviolet light to produce parts; the main difference is the light source used to cure the resin and how it’s selectively applying the light to the resin.

While MSLA 3D printers have surged in popularity and numbers while lowering the price in the last couple of years, DLP-based machines have remained expensive and the realm of dental labs of other professional spaces.

Not for long, though, perhaps. Anycubic teaming up with Texas Instruments to use the diminutive TI DLP Pico chipset for the Photon Ultra could mean the introduction of the DLP printing process to budget-conscious desktops in a meaningful way. Exciting days in the world of resin 3D printing! Anycubic’s Kickstarter campaign for the printer certainly isn’t short of backers – the target laughably exceeded with the ticker sitting pretty at $1.8-million.

So what exactly is DLP? And how does it differ from the MSLA tech used in all of Anycubic’s other resin 3D printers? Here’s how.

What Is DLP?

Digital light processing (DLP) as a 3D printing technology has its roots in image projection technology created in the late 1980s at Texas Instruments. Like their vat polymerization counterparts, DLP 3D printers are built around a resin tank with a transparent bottom and a manufacturing platform that descends into a resin tank. The printed object is produced “upside-down”, drawn up through the pool of resin layer by layer until complete.

The light source in a DLP 3D printer is typically a high-power LED or lamp unit, shining light onto a digital micromirror device (DMD.) This DMD is, essentially, an array of microscopic mirrors on a semiconductor chip. The mirrors precisely control where the light is projected, and generates the slice of a model (the layer) to be cured into the resin onto the build surface. The mirrors in the DMD can be thought of like pixels in a digital screen, the resulting projection a two-dimensional composed of square pixels, flashed onto the resin. This results in a layer formed from small rectangular blocks that, combined with a layer’s curing into the Z-axis, are called voxels (volumetric pixels.)

DLP vs. MSLA – The Differences

MSLA, on the other hand, uses an LCD to mask layer images onto the resin. Each layer is cured with the screen either blocking or allowing light from a UV light source beneath it to pass through the pixels that are “on”, creating a mask (hence masked stereolithography).

In a nutshell, DLP is directing the light specifically to where it needs to be for a layer, from one small focal point beneath the resin and build plate. MSLA, however, fires a wall of light at an LCD that actively masks the layer, allowing the necessary light through and blocking the rest.

So, why go through the hassle to direct light with precise mirror movements when the simplicity of masking a UV panel is on the cards, you might ask yourself. Well, DLP has some big upsides and seemingly few downsides.

The Pros

For one thing, there’s no light convergence. With an LCD printer, a single big UV light shines through a screen that has either open or closed pixels. However, the light always illuminates the whole screen, which can result in light leaks past the pixels that are supposed to be blocking the light. On a DLP printer, the projector shines concentrated beams of light only to where a given layer is supposed to form, resulting in incredibly crisp results without light leaks or blurry edges.

What’s more, whereas both technologies essentially light up pixels, DLP does not have a fixed resolution as you have with MSLA 3D printers. In short, the accuracy of an MSLA printer is determined by screen size and resolution. Projectors, however, aren’t locked into screen size. You also have a fixed number of pixels, but, like with a home projector, this can scale up or down, resulting in larger or smaller projections (and therefore pixels.)

This means that small models with intricate details (such as those required by dental professionals and artists) can be a lot sharper when printed with some DLP systems. However, this quality will depend on how spread out objects on a given layer are. Two objects on opposite sides of the build volume will suffer compared to two placed close together.

Another significant advantage is the longevity of the tech. If you’ve worked an MSLA printer hard, you’ll know that the LCD panels they use to mask will gradually burn out and need to be replaced. This can take ~2000 hours on a monochrome LCD panel.

The light source in the DLP tech lasts much longer (claims of up to 20000 hours of use) and will fail all at once instead of gradually.

The Cons

If you break it down, there don’t seem to be too many drawbacks to the DLP technology. It is as fast as the current top MSLA tech with layer cure times of about 1-2 seconds, and the projection device is claimed to last considerably longer. Add in that you can print at ultra-fine detail, provided you keep your print small sounds pretty enticing. Obviously, on the flip side of things, if you are gunning for build-plate-filling print jobs, DLP has its limits when it comes to granularity. A fixed micron resolution, as on MSLA printers, might yield better results.

Historically you could say that cost was a drawback of DLP for hobbyists, but it seems that Anycubic and TI may be on track to deal with that.

So, what do you make of a cheaper DLP printer? Is this a new chapter in budget desktop printing or just a niche thing? Let us know in the comments below.

(Lead image source: Anycubic)

License: The text of "Anycubic Photon Ultra – What Even Is DLP?" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.