AON3D is launching the AON-M2 2020, a high-temperature industrial 3D printer designed to print ultra high-performance thermoplastics like PEEK, PEKK, ULTEM™, polycarbonate, and hundreds of other materials.

This is the company’s latest industrial machine in its flagship product line. It’s ideal for fabricating parts for a wide range of applications, from tooling to jigs and fixtures, to end-use parts and rapid prototyping.

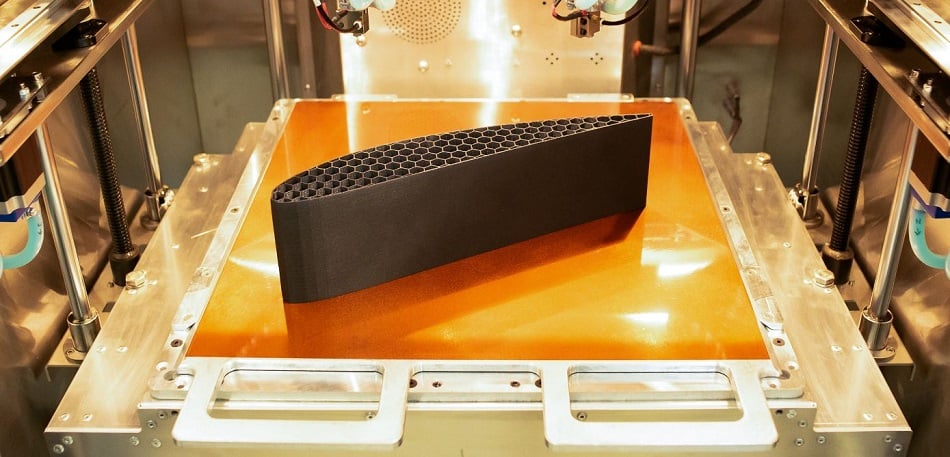

The AON-M2 2020’s extensive material compatibility empowers customers to realize the most demanding applications since the 3D printed parts can resist harsh chemicals, withstand extreme temperatures, and won’t buckle under intense mechanical stress.

“We are seeing a growing demand for an additive manufacturing platform that can print the strongest thermoplastics, as well as an increasing recognition that reaching the maximum mechanical property potential for any part-material combination is a challenge best met with expert support,” said R&D director Andrew Walker.

“The AON-M2 2020 is the bedrock of a complete solution we offer customers for getting from CAD file to end-use parts, without sacrificing affordability.”

Open Materials Printer Unlocks More Applications

Unlike many other 3D printing companies, AON3D has been committed to the open materials standard since it was founded and does not restrict customers to a limited selection of costly, proprietary materials.

Instead, the company has focused its materials engineering expertise to develop optimized process parameters for notable brands that provide the highest quality materials on the market. These vendors include Solvay, Sabic, Kimya, DSM, Infinite Material Solutions, and many others, so you can use the machine you trust with the materials you trust.

Superior Design for Superior Results

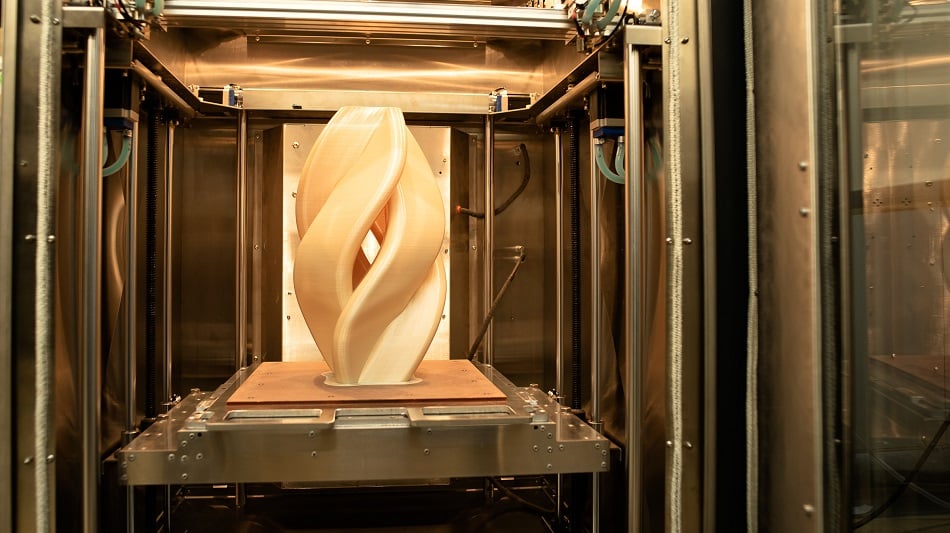

The machine is designed to reach the maximum potential of your materials, with a focus on part accuracy and repeatability, as well as reliability. It boasts an all-stainless-steel frame to minimize thermal expansion, a chamber heater redesign for precise control of the thermal environment, and it heats up in fewer than 15 minutes.

The huge printing chamber boasts a build volume of 454 x 454 x 640 mm and can reach temperatures above 135 °C (275 °F). The bed and hot end can reach temperatures of 200 °C (392 °F) and 470 °C (878 °F) respectively. It also has dual independent tool heads to easily print complex designs with support materials.

The impressive features of the AON-M2 2020 unlock an even wider range of high-performance materials that are in demand by industries such as aerospace, defense, R&D, and manufacturing.

“The AON-M2 2020 is an exciting step-up for AON3D,” said CEO Kevin Han. “We are thrilled to continue offering customers the widest range of material options for their applications and materials expertise that goes well beyond the machine design.”

The AON-M2 2020 is already shipping and you can get a quote today.

—

This content is sponsored and the views and opinions expressed within it do not necessarily reflect All3DP’s editorial stance.

For more information, please see our Terms of Use.

License: The text of "AON3D Launches the AON-M2 2020: A 3D Printer Built for High-Performance Thermoplastics" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.