When entrepreneur Tim Pausch first saw the innovative 3D printed helmet padding system from 3D printer and materials manufacturer Carbon used in American sports helmets, he had the idea to adapt it to combat helmets.

“We started developing it and it took about a year to perfect because ballistic and bomb blast trauma is completely different from sports impact,” says Pausch, founder of Send Nods Nightvision, a German company specializing in research and development of defense industry products using 3D printing. “So our lattice structure padding needed to withstand and dissipate other types of forces.”

Carbon 3D printed lattice pads line the inside of the highest impact-rated football helmets in the NFL from brands Vicis and Riddell, as well as hockey helmets from CCM. These companies have taken the Carbon technology and designed their own lattice structures tuned to mitigate sport-specific impact and, in some cases, individual players’ head shapes.

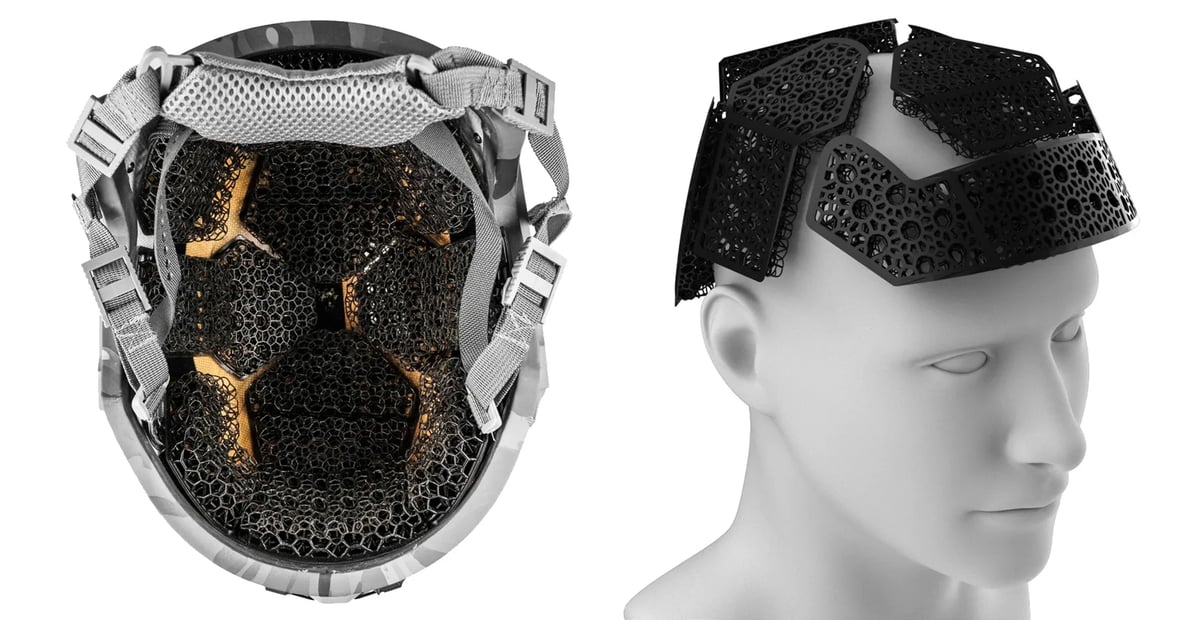

In fact, any company can develop lattice structures in Carbon software and 3D print them using proprietary materials on Carbon 3D printers. Pausch developed his own lattice structure design to combine comfort and safety, he says. The pads, called the AirPad System, are backed with Velcro and easily inserted into any helmet on the market to replace the standard foam pads. The pads are printed at third-party 3D printing service in Germany.

The AirPad System consists of nine individual latticed pads to replace standard foam pads. The initial design launched is optimal for heavier ballistic helmets, which are loaded with additional components like hearing protection, night vision, counterweights, and position lights to outfit soldiers in the field. Standard foams react by collapsing under the components’ weight and no longer provide dampening behavior, according to Carbon.

Comfortable, But Are They Functional?

Send Gear Group helmets’ AirPads, available through the distributor MSS Defence, feature two lattice layers. One is designed to absorb impact and reduce back face deformation, which is a term for the distortion or indentation that occurs on the inner surface of a helmet when subjected to a ballistic impact. The other layer is a larger-cell lattice to enable airflow and comfort.

“Most helmet padding is made of foam, so when it gets soaked with sweat, there is not only no breathability and extra heat, but the pad also loses its function,” says Pausch.

Pending the results of the company’s impact analysis and certifications, the helmet padding system is expected to be available in Europe beginning in April.

Already available in the US for more than a year, but not for export, is a helmet padding system by Hard Head Veterans that also features Carbon 3D printed lattice padding. The company’s Micro Lattice helmet pads for its tactical and ballistic helmets and others on the market, have been shown to decrease backface deformation by up to 66% over standard pads. The company also found a 21.7% decrease in blunt impact acceleration compared to standard pads, meaning that the pads slow the acceleration of forces transmitted through the helmet and padding to the head. The company’s independent testing took place at Testing, Inspection & Certification Services (NST). A new generation of the pads are now in development with the aim of cutting down on weight and increasing comfort, Director of Innovation and Growth Kit Dumph told All3DP.

Pausch is awaiting the results of his product testing, which are due in April.

Hard Head Veterans prints its padding systems at third-party printing services in the US, China, and Germany.

What’s the Military’s Take on Lattice-Pad Helmets?

In 2021, the US Army Development Command Soldier Center tasked start-up software company General Lattice with developing a predictive modeling toolset, essentially a piece of software, to design and generate lattice materials for helmets based on real-world data. The toolset, built on more than 10 million physical data points, is a searchable database that allows users to query lattice materials based on mechanical properties.

“Providing tools that enable users to understand the impact potential of lattice structure up front reduces the risk of adoption and builds confidence that 3D printing can deliver as advertised,” says General Lattice’s co-founder Nick Florek.

The Army is holding on to its toolset and hasn’t announced any plans to manufacture lattice padding for combat use.

License: The text of "Armed for Innovation: Fortifying Tactical Helmets with 3D Printing" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.