At All3DP, we’ve see a lot of new technology debut at Formnext. Unfortunately a lot of it flounders or simply vanishes. This is why we love seeing a start-up actually debut then grow, gain adoption, and evolve.

We talking about Axtra3D, the US-Italian resin 3D printer maker that specializes in a process that uses both a laser, like traditional SLA, and a projection engine, like DLP. The result is fine detail where you need it and speed where you want it. The idea, and the company’s application of it in its Lumina X1 3D printer, has caught on. Now, through development partnerships with major material makers, customers can print in truly industrial materials, including a new silicone.

“These new resins reflect our commitment to designing materials that meet challenging customer needs,” says Rajeev Kulkarni, CSO at Axtra 3D. “By collaborating closely with customers, we ensure that every new material has a clear end-use application, accelerating innovation and aligning with the precision and performance demands of key industries.”

The Six New Materials for Specific Applications

Available now, the six new materials are designed with specific real-world applications in mind. These additions raise the Lumina X1 material menu to 19. Technical data sheets are available online at Axtra3D.

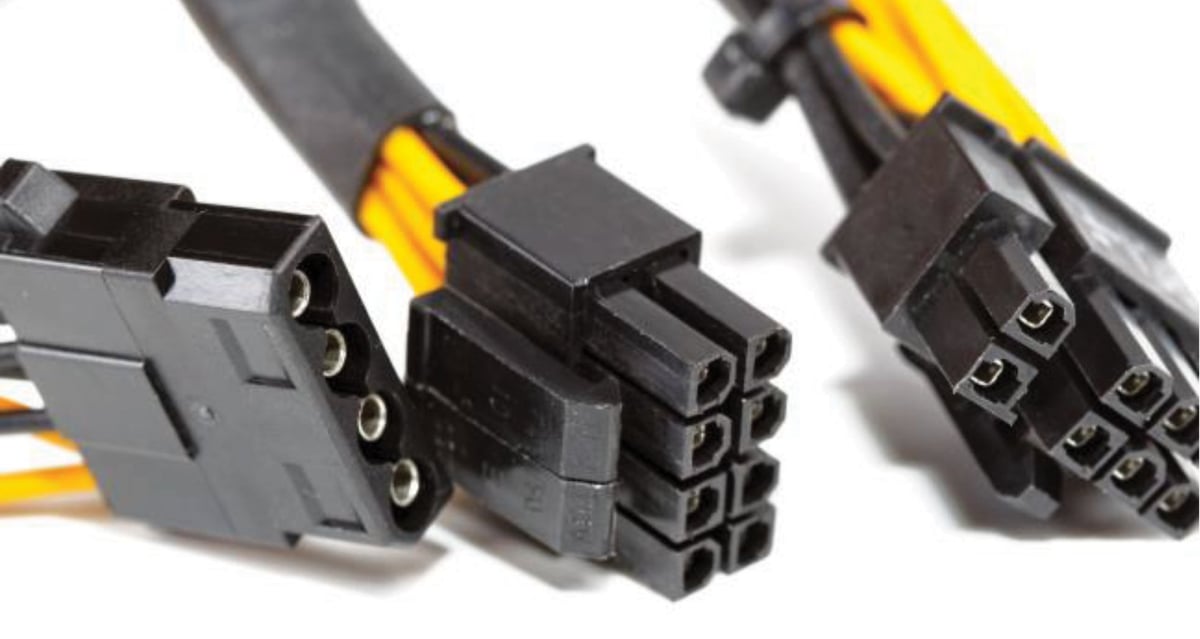

- Electrical connector applications with flame retardance: A fire-retardant, high-strength resin with a UL-94 rating of V-0 at 0.8mm is made by Arkema and officially called N3D-FR512.

- Seals, gaskets, prosthetics, and audiology components. These applications need the rubber-like features of silicone. This resin, TruSil-X50 from Spectroplast mimics the properties of traditional silicone.

- Manufacturing aids & connectors. These parts need high strength, stiffness and thermal durability. The new Loctite IND 249 from Henkel also has high green strength to enable easy processing.

- Silicone casting molds. Developed with mold applications in mind, Ultracur ST 45 B from Forward AM combines strength and thermal stability for high-detail molding and ease of demolding.

- Low-pressure molding applications. Another materials focused on low-pressure molding, particularly for large, durable parts like shoe soles and other oversized components. This polyurethane-based resin, Ultracur RG 1100 from Forward AM, provides mechanical properties comparable to injection-molding grades.

- Electronic manufacturing and tooling. This resin, Loctite IND 3380 from Henkel, with electrostatic dissipative properties is ideal for applications such as jigs, fixtures, and tooling where control over static discharge is crucial.

Axtra 3D operates with two business models: Axtra Solutions provides a turnkey 3D printing environment with print profiles or the Axtra OpenAccess where you can experiment with new materials and settings.

You May Also Like:

License: The text of "Axtra3D’s Laser & DLP Resin Combo Expands Materials, Including a New Silicone" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.