The folks at the Nissan production plant in Spain might be the inspiration behind the new Omega I60 from BCN3D. Nissan adopted BCN3D’s other 3D printers, the Epsilon series, some years ago to produce jigs, fixtures, and all types of shop-floor tools. By all accounts, the partnership was – and is – mutually beneficial, but if you look closely at the new Omega, you can almost see an Epsilon W50 in shop overalls.

The Omega is bigger, sturdier, and has a heated chamber and bed to make quick work (300 mm/s) of dimensionally accurate tooling in heavy-duty materials, such as carbon fiber nylon. It has an integrated filament dryer for when you forget to put your materials away and an easy-swap nozzle change feature.

BCN3D took what users loved about the Epsilon — like the independent dual extruders (IDEX), XYZ autocalibration, and, let’s not forget, the affordable price tag — and fortified it into a shop-floor workhorse.

The I60, which is an open-material platform (no fees), will sell for just over $20K, making it one of the most affordable, higher-temp FDMs on the market. Let’s take a closer look.

Heated Ambitions

The Omega I60 is BCN3D’s first printer with an actively heated chamber that the company says can not only hold a consistent temperature close to the material’s glass transition temperature but it also “promotes relaxation and eliminates internal tensions during manufacturing, effectively preventing issues like warping and cracking,” which is the reason you’d want a heated chamber. After printing, the part undergoes a gradual cooling process. Proper cooldown is often a neglected step in part production but can make a huge difference in the dimensional accuracy and mechanical durability of your part.

The Epsilon has a passively heated chamber, meaning it’s heated by the heated bed. By contrast, the Omega I60’s chamber can reach 70ºC. This isn’t in the range of industrial FDMs, like Roboze or miniFactory, but the I60 isn’t aiming to print industrial materials like PEEK, PEKK, and ULTEM. Instead, its chamber is more than enough heat for ASA, ABS, and carbon-fiber-reinforced nylon.

Thought-Through Extruders

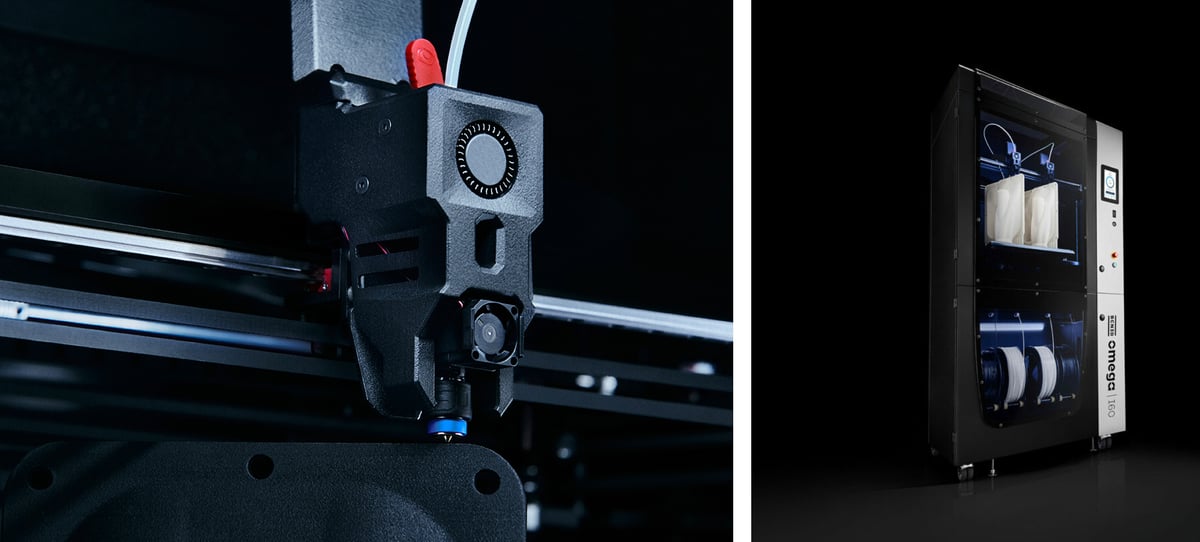

BCN3D has built a reputation for its multi-function independent dual extruders (IDEX), which enable you to not only print with a base material and a support material but can also be used independently. In other words, one extruder can print one part while the other extruder prints a completely different part (with some limitations), which is like having two printers running at the same time. The Omega I60 features what BCN3D is calling a “modernized version” of its IDEX technology.

The change involved keeping the X motors stationary during the printing process, which minimizes inertia, resulting in accelerated print speeds, the company says.

Under the hood, the I60 has some mechanical features you won’t find on a lot of other printers in this price range, such as a Haq-XY kinematics. This motion architecture is considered by many to be more stable for dual extruder 3D. BCN3D says the Omega I60 “utilizes an improved version of this kinematic system by placing the pulleys in a more optimal position. As a result, the system experiences a significant reduction in torsional moments along the X axis during the printing process.”

For its extrusion system, BCN3D Omega I60 turned to well-known component brands, including 1.75 mm direct drive Bondtech LGX Pro extruders and custom E3D Revo hotends.

Materials and Material Handling

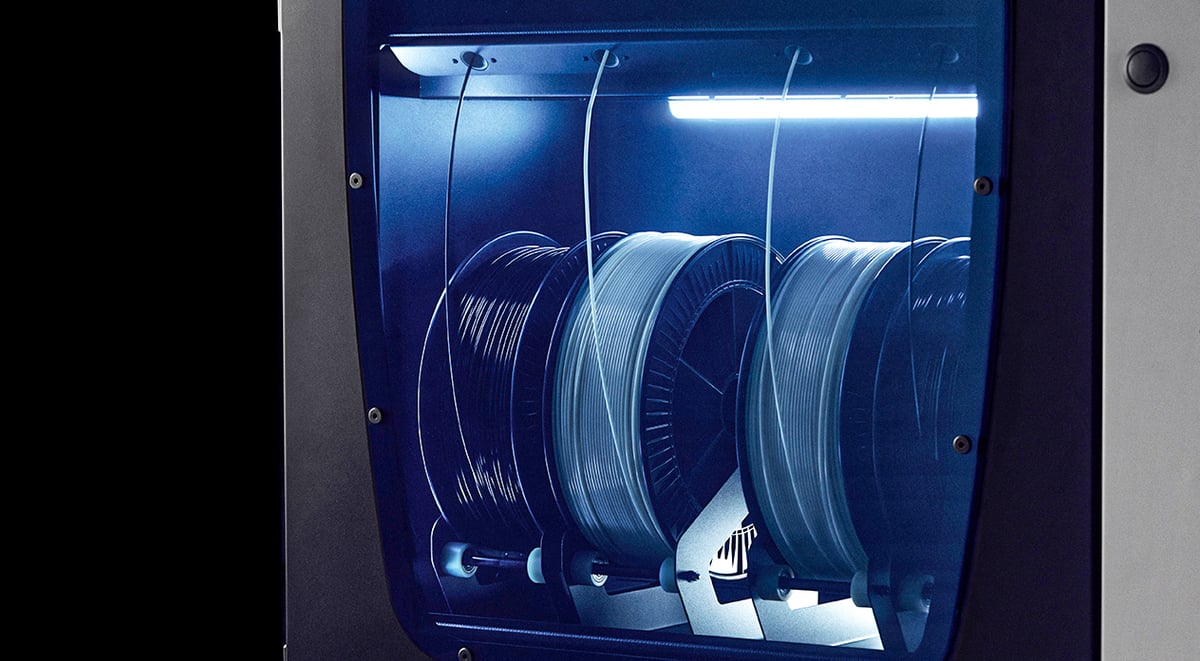

Incorporating the material handling unit into the printer architecture is a step we’re seeing across the professional FDM market. It reflects the importance of keeping materials in top shape to print.

The Omega I60 features a version of BCN3D Smart Cabinet build it, which can actively heat (up to 75ºC) and dry filament, recovering it from moisture exposure and keeping it at a humidity below 10%.

It also preheats your filament before starting a print. This is especially important for engineering materials with higher heat deflection temperatures. Perhaps taking a cue from the Ultimaker S7, the Omega I60 can keep four spools of filament at the ready and enables automatic filament barcode detection, loading, and unloading. So, if your print job runs out of filament halfway through, the machine will automatically change the filament for you.

Your Choice of Materials

A definite plus for the I60 is that you can print with pretty much any material you want. There’s no “unlocking” fee for the open material option. However, this machine is really aimed at users who don’t want to experiment with filaments or even have to know which type of polymer is best for which type of 3D printing.

For this user, BCN3D is introducing five new materials formulated for purpose. One for prototypes (Omega Proto), one for parts that can take impact (Omega Impact ASA), and others for wear and chemical resistance (Omega Resistant Nylon) and high-strength tooling (Omega Tooling CF). There’s also a new breakaway support material that works with all the Omega materials. Technical data sheets for these will be out soon, BCN3D says.

If you don’t want to go with the BCN3D filaments and their accompanying print profiles, you can choose from others in the company’s Open Filament Network, where BCN3D has collaborated with material manufacturers to create specialized printing profiles.

The BCN3D Omega I60 has other features that you’d expect to find on much more expensive machines, such as a built-in camera, a flexible build plate, an uninterruptible power supply (UPS), a 7-inch touchscreen, a HEPA and carbon air filter, a safety pause function, an emergency stop button and WiFi or Ethernet connectivity functions.

How To Get Your Hands on One

The Omega I60 is expected to be commercially available in September 2023, which isn’t that long to wait, but if you’re eager, you can join the company’s Omega Launchpad Program. This beta program lets you be among the first to explore the capabilities of the new printer and collaborate closely with a dedicated additive manufacturing applications engineer who will provide personalized assistance in analyzing and developing custom solutions specifically designed for the integration of the Omega I60 within your organization.

The program isn’t open to everyone. Although BCN3D has not revealed the criteria, chances are the more interesting your use case is, the more likely you’ll be selected.

Tech Specs & Price

- Technology: FDM

- Mechanics: Independent dual extruders (IDEX)

- Print volume: 450 x 300 x 450 mm

- Max extruder temp: 350ºC

- Heated chamber: to 70ºC

- Heated bed: to 120ºC

- Min layer height:0.05 mm

- Max print speed: 300 mm/s

- Price: $22,000

License: The text of "BCN3D’s New Fortified FDM Promises to Deliver Affordable Fixtures & Tools" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.