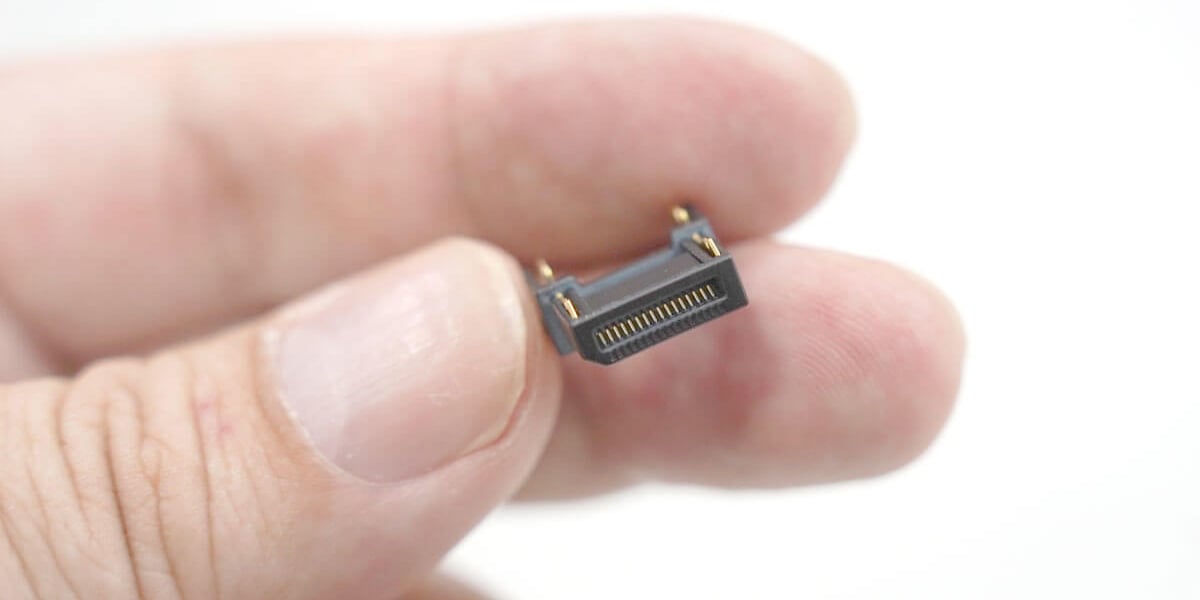

From healthcare to manufacturing to aerospace, so many industries need highly precise tiny parts. Boston Micro Fabrication (BMF), booth 1139, uses micro-stereolithography (PµSL) technology in its line of printers, boasting fast production times and resolutions between an astonishing 2 µm and 50 µm.

At this year’s Rapid + TCT, BMF is showing off its latest machine, MicroArch D1025, which is also powered by PµSL and based on BMF’s new hybrid resolution technology.

The MicroArch D1025 prints in either 10 µm or 25 µm resolution, or in hybrid mode with both resolutions in the same print layer or in different layers.

For engineers and researchers requiring extremely high resolution, the MicroArch D1025 delivers “improved built-in automation, which enables greater efficiency – saving time, resources and cost,” the company says.

Delivering the same ultra-high resolution, accuracy and precision BMF is known for, the new D1025 will “revolutionize the prototyping and production of parts requiring micron-level precision and repeatability,” the company says.

Using the company’s own specially formulated liquid polymers (or the material of your choice), MicroArch D1025 features a highly automated process boosting accuracy.

MicroArch D1025 Tech Specs & Price

- Technology: micro-stereolithography (PµSL) with digital light processing

- Build Volume: 100 x 100 x 50 mm

- Layer Height: 10- 50 μm

For more on everything happening at Rapid + TCT, including new product launches and events, visit the All3DP Rapid + TCT Special Coverage.

License: The text of "BMF at Rapid + TCT: Meet the MicroArch D1025 High-Precision Micro 3D Printer" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.