Real metal parts from an affordable desktop 3D printer were just an ambition not long ago. Metal filaments have been on the market for years, but online user forums were filled with reports of poor results. The problem, it would appear, was not with the materials or the printers but with the part design and the user practices.

“When using metallic powder filaments for metal 3D printing, micro-cracks or brittle spots on the models are the common issues users struggle with,” says Michal Siemaszko, head of research and development at 3D printer maker Zortrax. The reason for part failures, he says, is usually poor part design, including improper internal structures.

Addressing this, Zortrax, which just launched the ability to print metal parts on its Endural FDM printer, offers a metal 3D printing manual as part of its new Full Metal Package. Users can check their part design for printability against design guidelines.

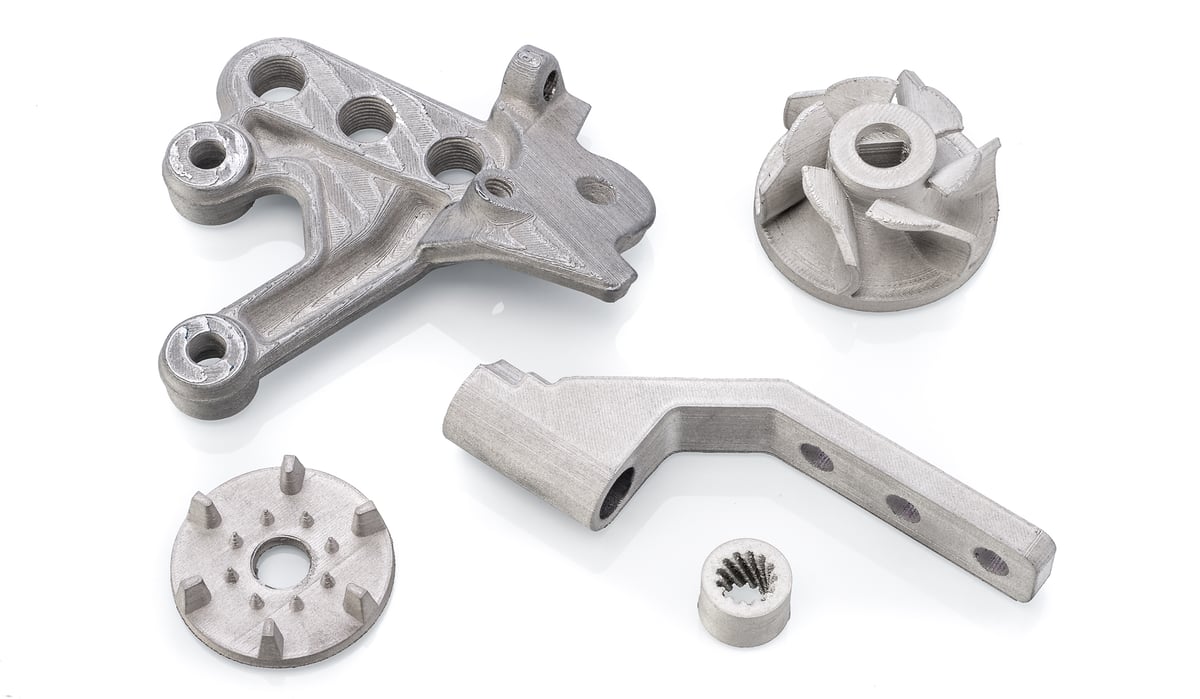

Successful metal 3D printing – for everything from jigs and fixtures to factory tools – relies on adherence to specific part measurements, according to the guide, including a design that accounts for a 20% shrinkage in post-processing, and specific height-to-width ratios. Other points to consider are the part orientation, wall thickness, and support structures. In the end, according to Zortrax, throw out what you know about 3D printing with plastics, metal 3D printing is a whole new ball game.

There’s More to Printing With Metal

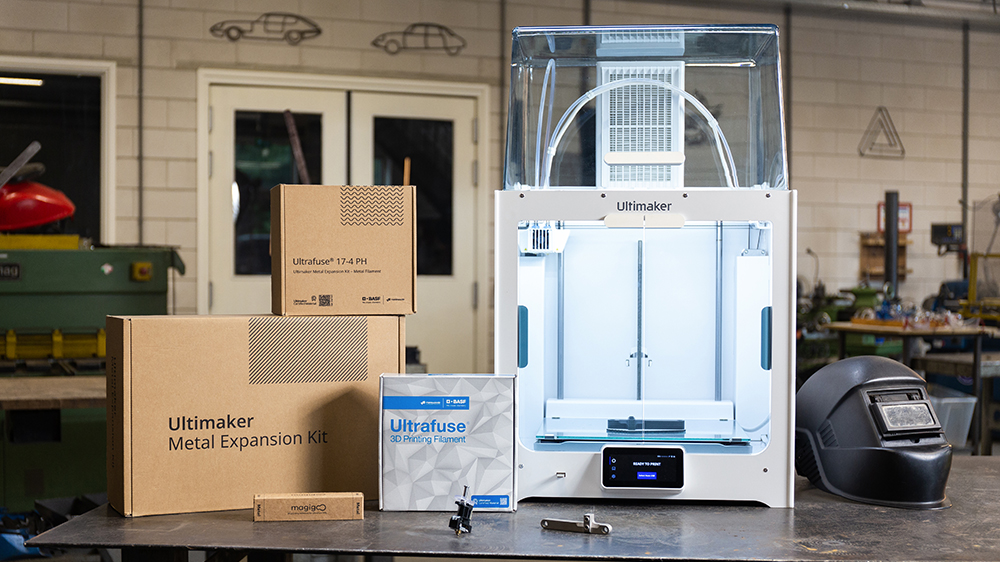

The essentials to metal 3D printing with filament, which are included in the Zortrax metal package, are metal filament, print guidelines, hardware accessories, and software. But this bundled approach to boosting success with metal 3D printing isn’t unique. Earlier this year, desktop 3D printer maker UltiMaker introduced its Metal Expansion Kit for metal 3D printing on its S5 professional 3D printer. The kit was explicitly developed to remove “existing process bottlenecks and limitations,” the company says, by providing users with all the ingredients for successful metal prints in one box. This is also the first foray into printing metal parts on the popular UltiMaker machine, which can also print with a wide range of plastics.

“The Ultimaker Metal Expansion Kit is especially suitable for printing non-of-the-shelf parts such as tools, jigs and fixtures, replacement parts, functional prototypes, and auxiliary components,” says Andrea Gasperini, product manager at Ultimaker. “The kit provides access to a complete and validated 3D printing workflow.”

The launch of UltiMaker’s Metal Expansion Kit coincided with the release of Cura 5.1 slicing software that includes a specific set of features used to prepare metal parts on the Ultimaker platform.

Months before the UltiMaker kit debuted, printer maker BCN3D launched its bundled solution for desktop metal 3D printing using metal filament in late 2021. The company’s Metal Pack, containing metal filament, accessories, and software, enables metal 3D printing to compete directly with current technologies, the company says, such as metal injection molding and CNC machining offering similar mechanical properties and far more design freedom. The BCN3D also contains specific design guidelines and process requirements.

What is Extrusion Metal Material?

What all of these kits have in common is the metal filament. BASF Forward AM, one of the largest chemical companies in the world, has a near monopoly on metal filament for desktop fused deposition modeling (FDM) 3D printers. The company has partnered with printer manufacturers to develop these kits and processes to ensure better success with its Ultrafuse metal filament material in two varieties: 17-4 PH stainless steel and 316l stainless steel.

“Ultrafuse metal filaments portfolio has been developed based on BASF’s decades of know-how coming from the metal injection molding (MIM) industry,” says Firat Hizal, head of the metal systems business group at BASF 3D Printing Solutions. The filaments can be used on a wide range of FDM printers, yet kits, along with software, are boosting success, the company says.

When correctly 3D printed, metal parts produced with an UltiMaker S5 and Ultrafuse 316l stainless steel filament have a tensile strength of 561 MPa in the XY (flat) and 521 MPa in the ZX (upright), Forward AM’s research shows. For comparison, an identical part manufactured with metal injection molding displayed a tensile strength of 540 MPa in both directions.

When it came to elongation at break, or the forces on the part as if it were lifting a heavy object, the 3D printed part was half as resistant along the layer lines (ZX) as the molded part but comparable in the XY direction. Print orientation, or determining where the layer lines will be, plays a major role in part performance.

Yield strength, or the stress corresponding to the point at which the material begins to deform, was significantly higher for the 3D printed part (251 MPa at XY, 234 MPa at ZX) than the molded part (180 MPa).

Ultrafuse offers two stainless steel materials. The first type is a stainless, surgical-grade 316l steel which is particularly resistant to corrosion due to the relatively high percentage of chromium in the alloy, according to Zortrax. Chromium, when it comes in contact with oxygen, forms a thin protective layer on the surface of parts, which prevents them from corroding.

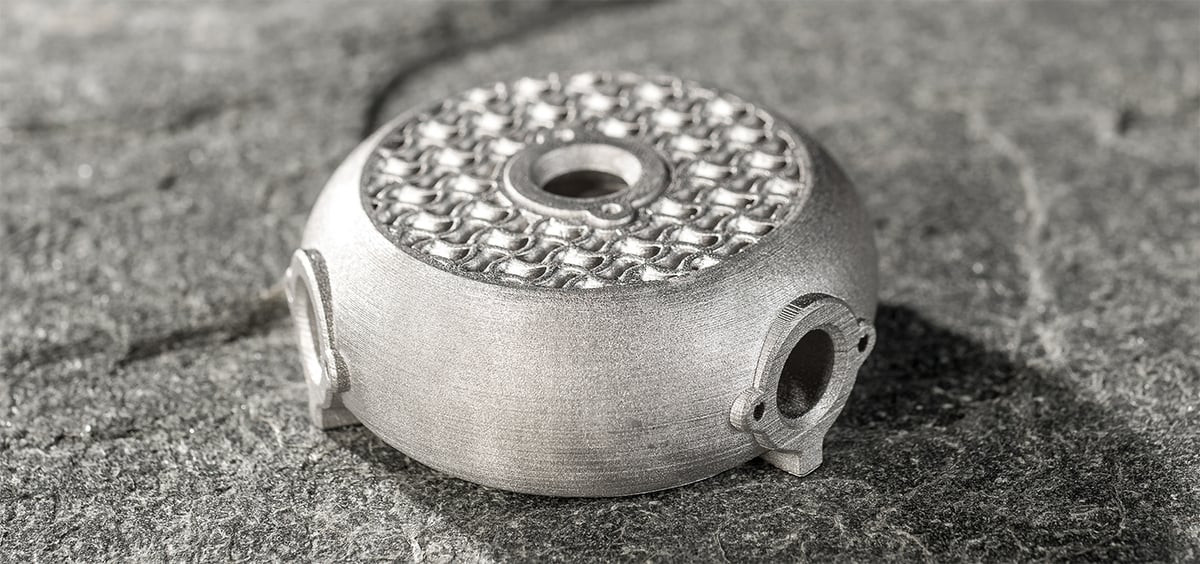

This makes 316l perform well in environments where parts are exposed to liquids, chemicals, or salt. The 316l steel is also aesthetically pleasing, especially after polishing to a mirror finish, which makes it a popular choice for decorative applications. This steel, however, is relatively soft and has high elongation at break, reaching 53%. It will bend rather than break under critical load.

The 17-4 PH steel 3D printing filament from BASF, on the other hand, is an alloy that has higher hardness due to the addition of carbon and undergoing a process called precipitation hardening. It has a lot lower elongation at break, measured at just 4%, but can withstand much higher loads with a tensile strength of 1004 MPa.

Metal 3D printed parts can be welded, machined, and sterilized if needed. Holes included in the designs can be threaded to make place for screws or bolts. “Basically, 3D printed steel behaves like any other steel,” according to Zortrax.

Special Support Layer Material

All three of the metal bundles mentioned above come with the Ultrafuse Support Layer filament developed to be used in combination with Ultrafuse metal filaments. When printed between the support and the metal object, it creates a barrier during sintering, facilitating the separation of supports from the metal part. Essentially, it makes breakaway supports, dramatically speeding up processing time and reducing labor. This support layer is printed with dual extruder 3D printers as a layer attached to the support structures. However currently, it’s only available in the EU and the UK, but plans are underway to introduce it to North America.

Mailing Off Your Metal Part

Although desktop metal 3D printing with filament has seen steady growth in the past two years, there have been other hurdles to wider adoption. Extrusion-based metal 3D printing does not produce a usable metal part right from the printer. The process requires users to mail their parts to a third-party company to be processed.

The process for finishing the metal part, which includes debinding the polymer from the metal and then sintering the metal part in a high-temperature oven, is another critical step for strong parts. Instead of offering debinding in the kit and selling a furnace, Zortrax, UltiMaker, BCN3D, and others facilitate shipping your parts to a vetted third-party post-processing house. Apparently, this was a step better left to metal-processing professionals.

Zortrax’s new Full Metal Package includes a voucher to cover the cost of sintering and bubble wrap. The similar kits from UltiMaker and BCN3D also include partnerships with post-processing companies in Europe in the US.

Not Every Desktop FDM Can Go Metal

Another practice leading to failed metal prints on desktop extrusion 3D printers, printer manufacturers say, is failure to follow the recommended hardware requirements.

Metal 3D printing requires a hardened steel hot end, not the brass hot end most FDM 3D printers come with. The hot end must also be able to reach a temperature of about 220 ºC, and the printer must have a heated bed to about 80 ºC. These are not standard features on most consumer desktop 3D printers.

Printer software specifically for metal 3D parts has added another layer of safeguards to successful prints. Called slicing software, these programs send instructions to the machine on printing the part. They have dozens, if not hundreds, of possible settings. Zortrax, UltiMaker, and other printer makers now provide the ideal setting for printing Untrafuse in a print profile, which vastly reduces the margin for error in prints. These software settings not only automatically scale the part to accommodate for shrinkage in post-processing but can detail metal-specific infill types.

A validated process for metal 3D printing on machines that were originally designed for plastics enables users to switch between printing plastics and metal parts back-to-back, says Hizal at BASF Forward AM. Knowing that the metal 3D printing process is more complex than using standard polymer filaments, successful applications may continue to rise.

Application Areas for Desktop Metal 3D Printing

Like many component manufacturers, Liebherr-Components Colmar in France, which makes mechanical, hydraulic, and electrical drive system components for mining trucks, excavators, and power generation, had a infrequent need for a critical engine bracket. When traditionally manufactured using CNC machining, the low volume requirements result in a part cost of up to $102 each. The time required to machine these parts also results in months of lead time.

After using their research and development expertise to validate the potential of metal 3D printing, Liebherr Components and BASF developed a new design that exceeded current load cases for the bracket while reducing the mass of the original bracket by nearly 60%. The redesign and 3D printing provided three times the load-bearing capacity for added safety. The cost of the new part was almost halved and lead time was reduced to weeks, providing a much better ROI.

In another example, the team of Motorcross Racing Technologists at Kawasaki Motors Corp., USA, who design many of the specific components for Kawasaki Motocross Racing motorcycles, needed a solution to a motorbike shift lever. The original design required multiple jigs and two specialized CNC machines to produce. Rider-specific customizations of this component were costly and time-consuming to implement.

With metal filament 3D printing on their UltiMaker, the team now makes custom shift levers for each rider without needing to make new fixtures or CNC programming. The new 17-4PH stainless steel material also lasts far longer than the previous aluminum component that would wear out in six hours of riding. The result is a much more cost-effective part (about $13) with increased options for customization and improvement.

Alstom is a mobility solutions company developing high-speed trains and subway infrastructure. Their need was for lower cost yet appealing and strong low-volume doorstoppers for a partition door dividing the passenger compartments of a diesel train.

By working with Replique, a 3D printing on-demand manufacturer, for sample testing, they concluded that Ultrafuse filament and the BCN3D 3D printer provided the durability and aesthetics required. The part needed to last the service life of the train. On top of that, since it would be seen inside the train compartment, it needed to have the desired aesthetics.

“We were able to produce the doorstopper in a cost-neutral manner compared to conventional methods,” says Ben Boese, 3D printing hub manager of Alstom Transport Deutschland. “Within the near future, we plan to further exploit the technology’s potential by creating topology-optimized designs of new parts or even make them lighter by using reduced infill.”

License: The text of "Can Reliable Metal Parts Come From Desktop 3D Printers?" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.