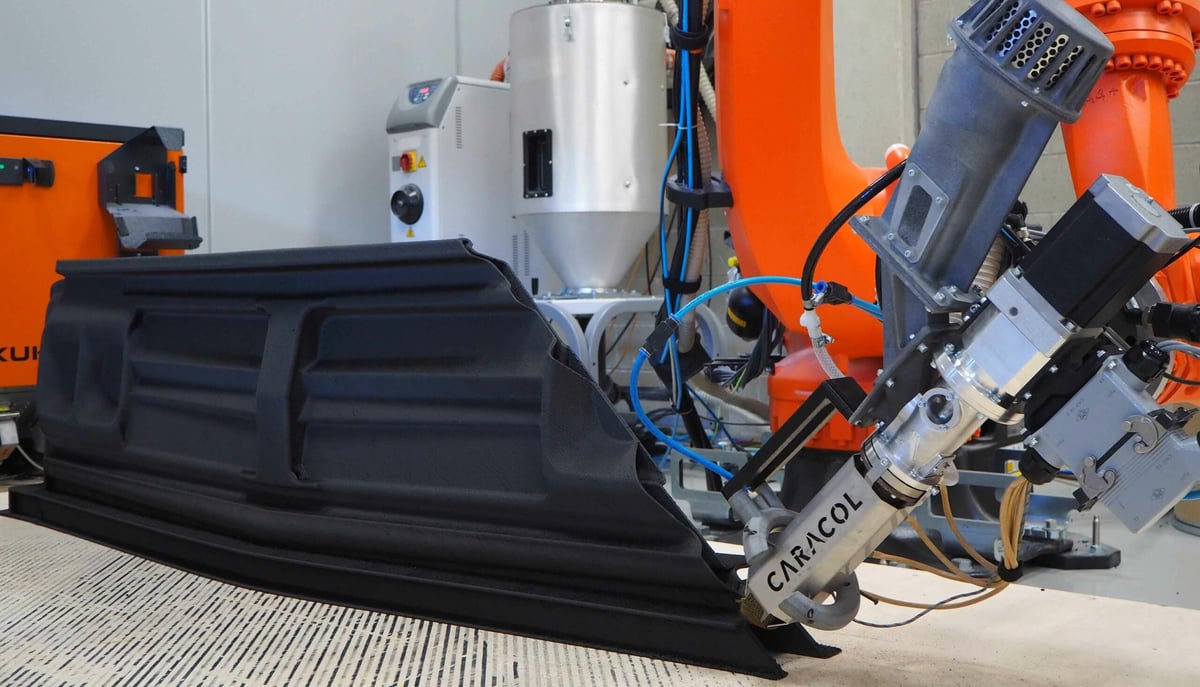

After making a name for itself as a 3D printing service featuring large-format robotic arm extrusion 3D printers with custom-designed print heads, Italy-based Caracol AM launched its first large format polymer extrusion 3D printer, Heron AM, in 2022. This week it takes a bold new step into metal 3D printing with the launch of Vipra AM.

“With Vipra AM, we’ve leveraged the extensive know-how developed over years working on advanced process control and software for large format AM with thermoplastics and composites materials, to develop a proprietary cutting-edge metal platform that combines state-of-the-art hardware and software, with advanced robotic monitoring and automation,” says Francesco De Stefano, CEO of Caracol AM.

Vipra AM, available in two configurations (XQ and XP), is a directed energy deposition (DED) 3D printer, or more specifically, a wire arc additive manufacturing (WAAM) 3D printer. This type of 3D printing uses metal wire as the material and a plasma arc as an energy source, similar to welding. The arc melts the wire as it’s deposited layer on top of layer by a robotic arm onto a surface, such as a multi-axis turntable.

This method of 3D printing has actually been employed in heavy industry and aerospace for years, but it’s come a long way. Today, it’s being eyed as a way manufacturing, heavy industry, defense, and aerospace can produce large metal parts at a fraction of the time and cost of traditional forging, castings, or machining. It also may be a solution for clogged industry supply chains, market pressures to innovate, sustainability targets, and faster repair and spare part delivery.

There is not a crowded field when it comes to WAAM 3D printers with just about seven companies on the market with platform solutions, including AML3D, WAAM3D, Gefertec, Norsk Titanium, MX3D, RamLab, and MetalWorm.

What Sets the Vipra Apart?

This is what we’d also like to know, but Caracol AM is short on details and photos before the official Nov. 19 launch at Formnext.

Both Vipra configurations are focused on applications such as load bearing finished parts; lightweight structures; high-temperature, high durability autoclave and curing molds; plus cladding, repair, and on-demand spare parts.

The Vipra XQ configuration focuses on production components with “exceptional finishing and precision,” the company says. It can process a broad range of metals, including stainless steels and titanium alloys. Caracol AM says this system is geared for large-scale parts for sectors such as aerospace (e.g. load-bearing brackets and structural components) and energy (e.g. valves, gauges and structural piping connectors).

The Vipra XP configuration is focused on speed and throughput (and less so on precision) to maximizing productivity, the company says. This edition can also print with aluminum and nickel-based materials critical in industries, such as transportation (e.g. automotive components, aerospace pressure vessels, marine propellers) and lower-end architectural applications (e.g. sculptures, lightweight organic structures).

Vipra AM is a turnkey solution including proprietary hardware and software.

“At Caracol, we believe that the future of manufacturing lies in combining a strong application focus with advanced innovative technologies that reshape the capabilities of industrial production lines,” states Francesco De Stefano, CEO of Caracol AM.

Caracol’s new robotic platform will be unveiled at Formnext (booth C101 Hall 12.1) on Nov. 19.

Visit our Formnext 2024 micro site for all the printer launches and news before, during, and after the event.

You May Also Like:

License: The text of "Caracol AM Launches Large-Format Metal 3D Printer at Formnext 2024" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.