Swiss Scheurer GmbH, a Swiss engineering company, announced in a press release they succeeded in making large carbon-reinforced 3D printed parts to be installed in a high-tech catamaran.

A “unique bonding mechanism” made it possible to 3D print these parts, which are being used in a titanium rudder bearing system on the vessel, said the company.

Dominik Scheurer, the CEO of Swiss Scheurer, utilized his engineering experience with Formula 1 to produce these carbon-reinforced 3D printed parts for the ‘Moonwave’ catamaran. Along with production support engineer Robert Tween, Scheurer worked for many years selecting composite materials and designs for racing car parts with high mechanical performance.

Scheurer and his team successfully 3D printed components commissioned by the crew of the luxury catamaran. Given the nature of the build material, the size of the final part is rather noteworthy.

Advanced Composite Printing at Scale

Swiss Scheurer already has experience making composite parts for “aerospace, racing and motorsports, defense and security as well as industry,” it said in its press release.

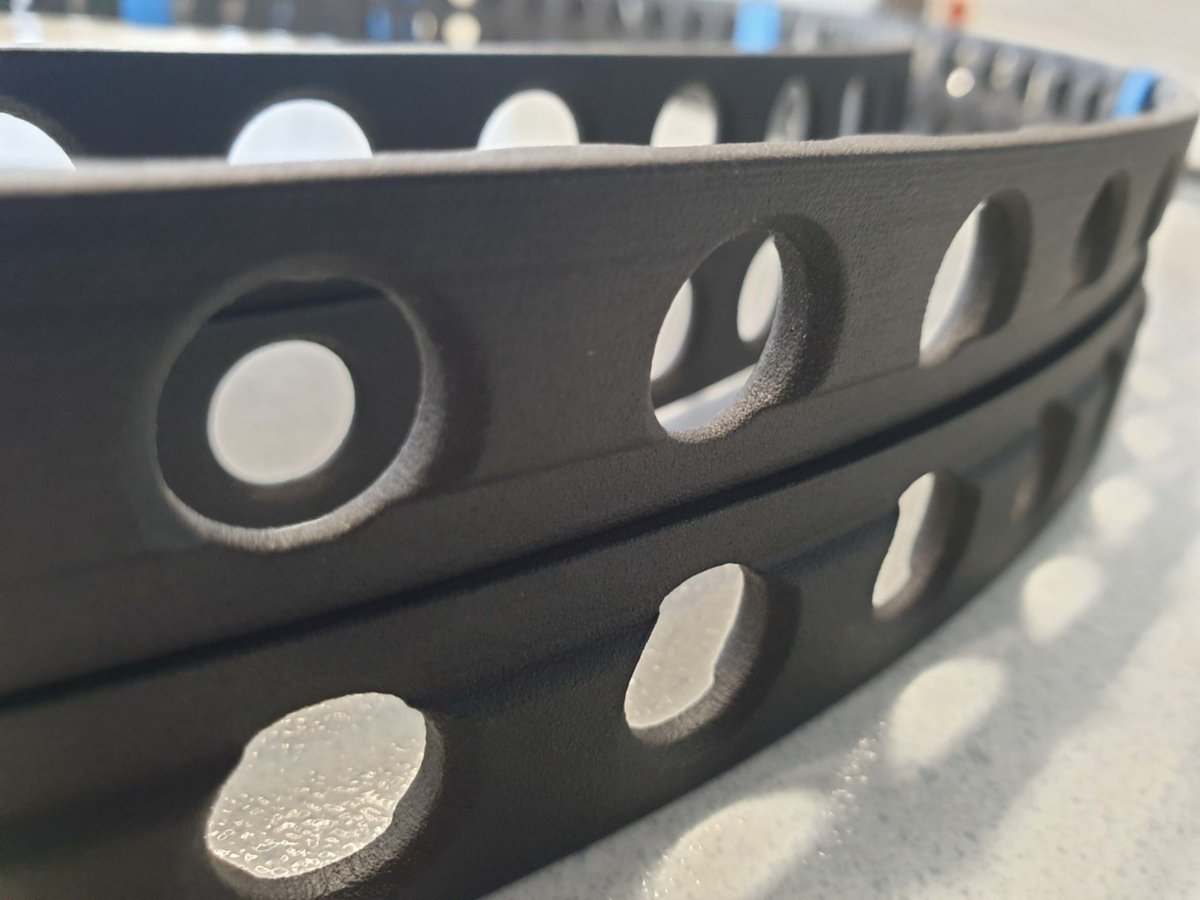

It designed a bearing cage made with carbon-reinforced composite with a diameter of 630 mm to aid the steering of the catamaran. A special bonding mechanism made it possible to fabricate a part of this size and strength.

The 3D printed part had to meet higher standards of strength and performance compared to other 3D printing applications in sea vessels. This was because they function as part of a state-of-the-art steering system for the catamaran, rather than just a design element.

Source: Press release

License: The text of "Carbon-reinforced Parts 3D Printed for Luxury Catamaran" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.