Perhaps more so than any other field, the automotive industry has greatly benefited from 3D printing. The technology has been adopted by car companies across the world, including high-end brands. From functional prototyping to customized real-use parts, additive manufacturing has bolstered car manufacturers’ ability to innovate and bring game-changing ideas to life.

To leverage the value of 3D printing technology, you don’t need to have a professional 3D printer on the production floor. There are several 3D printing services, such as 3DEXPERIENCE Make from Dassault Systèmes, that handle the manufacturing of 3D printed parts – while also offering design assistance and additive manufacturing know-how.

3DEXPERIENCE Make was recently commissioned to produce an automotive marvel that serves as the definitive use case for how 3D printing can be used to improve the way cars look, function, and ultimately impact the world. Working with its French partner TH Industrie, experts in the production of technical and functional plastic parts, the on-demand manufacturing service worked with its client Conspectiv to create an extraordinary 3D printed 3-wheeled electric car.

Let’s take a closer look at this project and how it could have only been conceptualized with 3D printing technology at the helm.

3DEXPERIENCE Make Helps Conspectiv Create Sleek 3D Printed Electric Car

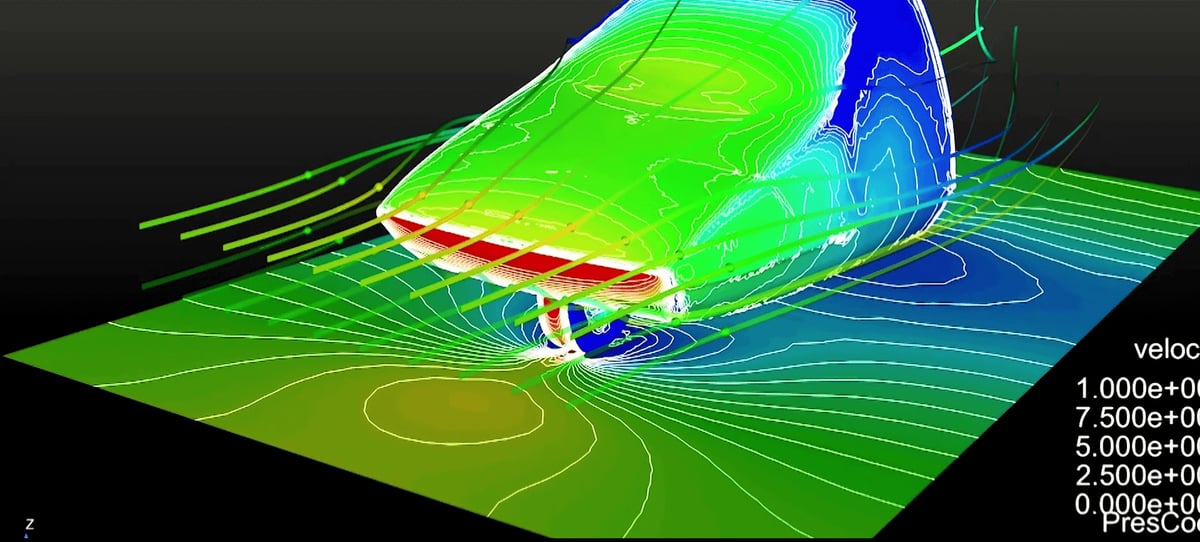

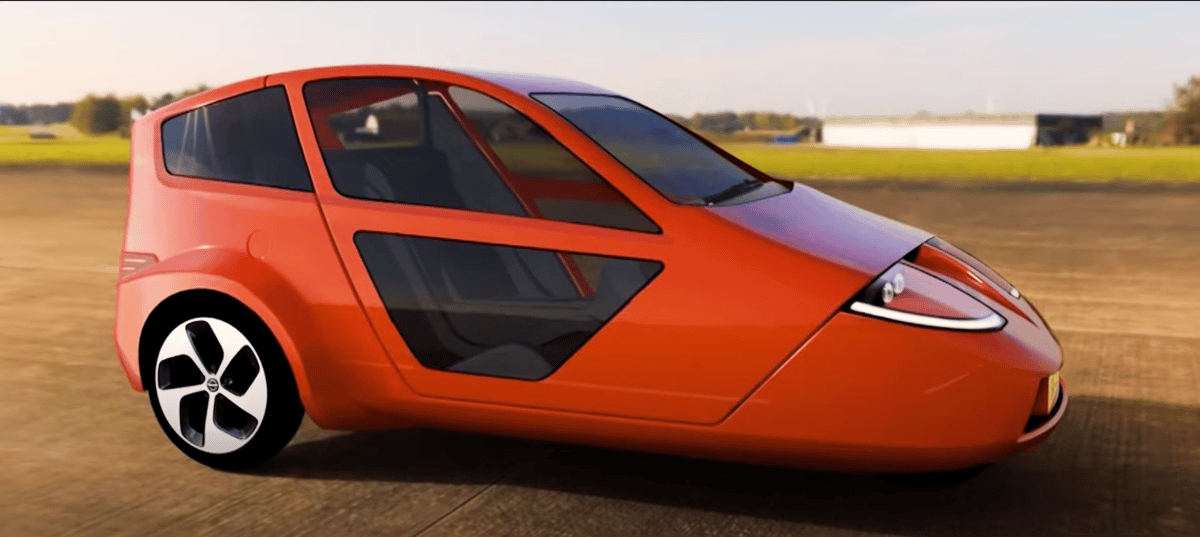

The concept behind this car was born from the client’s wish to design a classic car, but with a modern twist of being fully electric. Conspectiv, a London based design firm, ventured to an urban supercar, dubbed as the Bug 2E, that kept the aerodynamic drag low, a necessity in ensuring a high-performance electric vehicle.

While doing research on the internet, they came across Dassault Systèmes’ 3DEXPERIENCE Marketplace and connected with its Make on-demand manufacturing service. After uploading some car parts to the service, 3DEXPERIENCE Make got in touch with the designer to ensure that the production process would suit the unusual needs of the client.

Impressed with the way the 3D printed car door came out, Conspectiv decided to go with the service provider and 3D print a number of other parts, including lights and various hinges, which are made of both plastic and metal. Using FDM 3D printing, the car body was produced with tough and durable ABS Kevlar plastic.

The final product is truly astonishing, a vehicle that surely will draw the attention of any passerby. Its eye-catching red color and sleekly curved design makes it fully unique, incomparable to any other mass produced car – let alone an electric car. What really makes this concept distinct is the three-wheeled design. This makes the 3D printed car compact, yet powerful enough to speed around urban areas

TH Industrie, a partner on the 3DEXPERIENCE Make service, was key in the production process. With more than 50 manufacturing machines and over 30 materials available to customers, Conspectiv and 3DEXPERIENCE Make were able to nail down the exact process and material needed for the project.

Working with 3DEXPERIENCE Make and its partner TH Industrie presents several benefits that clients are unable to replicate when bringing production in-house. For example, using an on-demand manufacturing service means that clients don’t have to manage inventory, they can simply get the parts they need in a timely and efficient manner.

Secondly, instead of mass producing bulk parts, clients like Conspectiv can commission these production experts to produce a small amount of parts, making the entire process more cost-effective for the end-customer. For TH Industrie, 3D printing technology enables them to compete with overseas manufacturers in both pricing and timeliness, giving them a much-needed edge both in France and across the globe.

Needless to say, this project provides another notch in the reputation of 3D printing as a whole, as well as Dassault Systèmes commitment to support innovators who wish to leverage the technology. Additive manufacturing enables Conspectiv to design a quirky, high-performance vehicle that could only have been brought to life with the help of an on-demand manufacturing service like 3DEXPERIENCE Make.

For more information about 3DEXPERIENCE Make and its services, or to get a quote for your own project, visit the on-demand 3D printing service’s website here.