Creality, a global pioneer in 3D printing, has long been known for its wide array of consumer-centric desktop 3D printers. More recently, the manufacturer has also started to make headway in the professional 3D printing market, bringing its affordable and highly capable machines to the next level.

Creality has recently launched the Sermoon D3, a high-performance professional FDM 3D printer that has an industrial design and offers an intuitive solution for prototyping, jigs & fixtures making, design verification, and more.

In addition to the new 3D printer, Creality is also working with Forward AM, a brand under BASF 3D Printing Solutions, to expand the capabilities of the Sermoon D3. The partnership will combine each company’s capabilities to develop and promote its co-branded filament series, which includes specially formulated HP-ULTRA PLA and ABS.

Together, the two companies have tested and optimized the filament to ensure the optimal performance on Creality’s professional-grade 3D printers. Aiming to accelerate the adoption of 3D printing in various fields, the two parties will also work closely to explore innovative additive manufacturing applications in industrial sectors, such as general manufacturing, automotive, medical, and education.

Sermoon D3 3D Printer: Made for Industrial Design

For 3D printing to properly integrate into the professional setting, there must be reassurances around stability, durability, and repeatability. The Creality team has ensured that the Sermoon D3 is meticulously tested and checks off all of the boxes.

Sermoon D3 features industrial-grade stability tested and certified by Forward AM’s Additive Manufacturing Technical Centre (AMTC) and Creality Lab. With a sturdy steel bottom plate, an 8mm aerospace aluminum top plate and four vertical aerospace aluminum profiles, Sermoon D3 can achieve 720 hours (or 30 days) of non-stop printing and 8,000 hours of failure-free printing according to the testing data from Creality Lab.

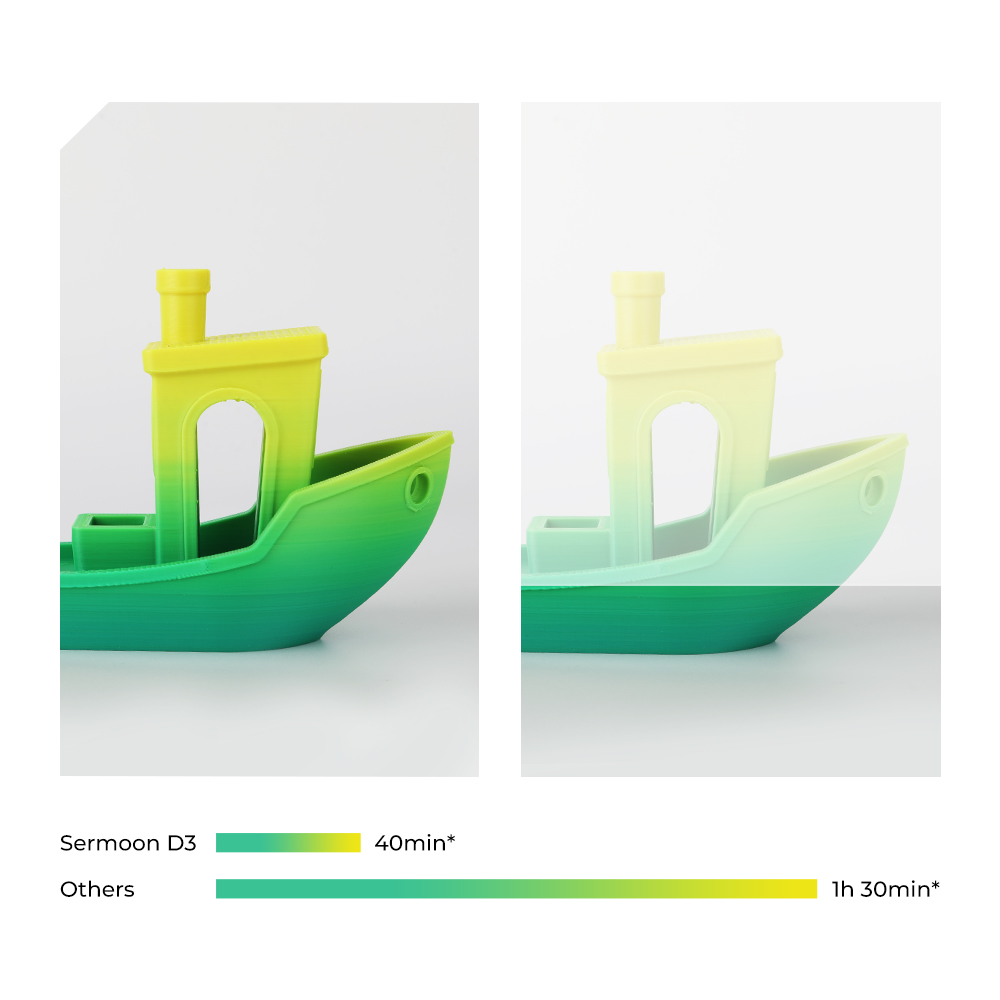

This professional 3D printer is also engineered for intuitive and high-speed production. Users can connect to multiple Sermoon D3 printers simultaneously via LAN or WiFi, allowing them to control and monitor the printing process through Creality Print or Creality Cloud App on PC or smartphone. With a sizeable 300 × 250 × 300mm build volume and up to five times of speed, Sermoon D3 significantly scales up the production in a cost-effective way, allowing users to print quickly and without limitations.

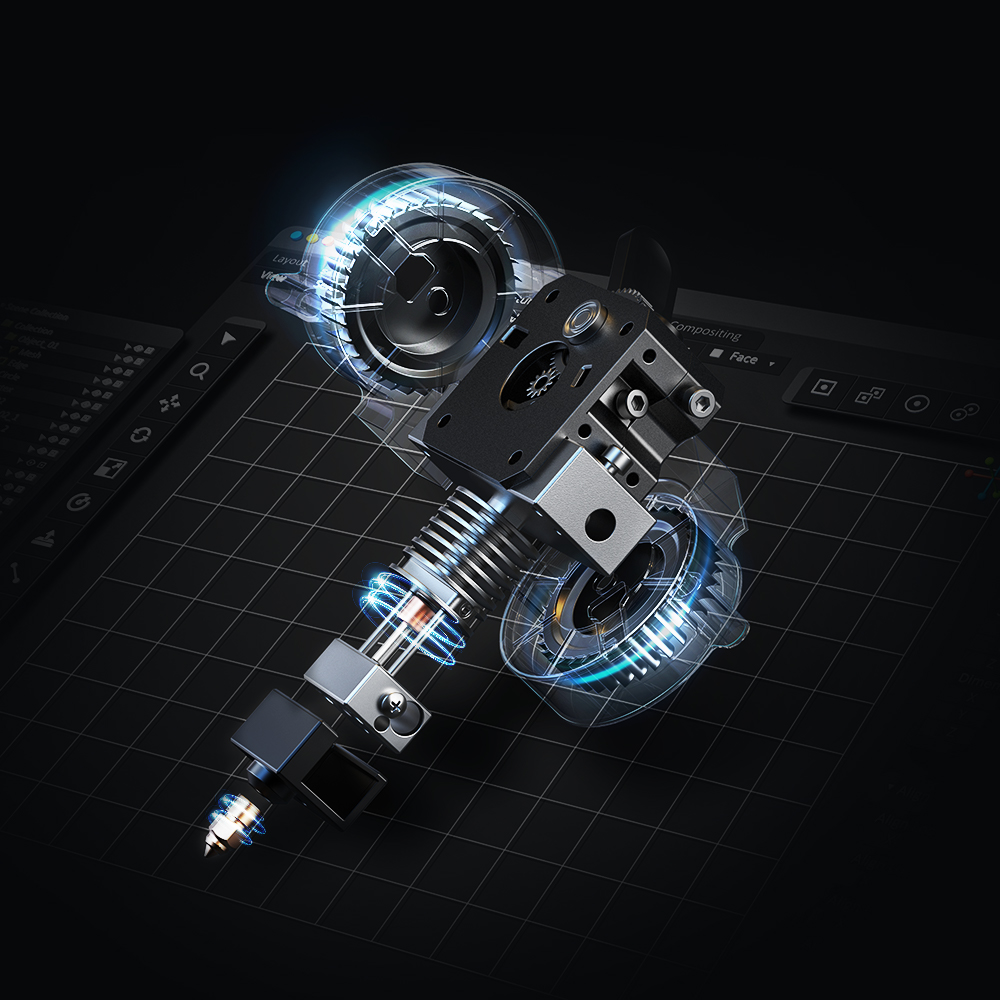

To ensure compatibility with a wide range of high-performance filaments, Sermoon D3 is equipped with an upgraded sprite dual-gear direct extruder with bimetal heat break made of copper alloy and titanium alloy. The two 5015 large cooling fans help avoid charring and allow the print to solidify faster. This enhanced design enables consistent extrusion at temperatures of up to 300℃.

Creaility has secured CE, FCC and UKCA certifications, among others, for its Sermoon D3, verifying the reliability and safety of the machine. The 3D printer comes with an interchangeable PC and a PEI spring steel sheet, as well as a professional tool kit with an extra hardened steel nozzle.

Creality and Forward AM Bring Tested Material Compatibility to the Table

When using traditional manufacturing methods in prototyping and design verifications, businesses face a lengthy and costly development cycle, limited choice of materials, and material waste due to molding failure. As Creality’s latest foray into the professional-grade market, Sermoon D3 offers industrial-grade stability that has been tested and certified by Forward AM’s Additive Manufacturing Technical Centre (AMTC). This professional 3D printer brings cost-effective 3D printing solutions to professional users and small enterprises that they can trust.

When looking at the advantages that 3D printing offers to small businesses and pro users, the advantages are clear. Take machinery design as an example. With traditional manufacturing, it can take at least 20 working days to design, review, proof, and modify the design. However, by utilizing 3D printing technology, users can achieve rapid prototyping in less than 10 working days, shortening the R&D cycle, improving overall efficiency, and saving time and cost.

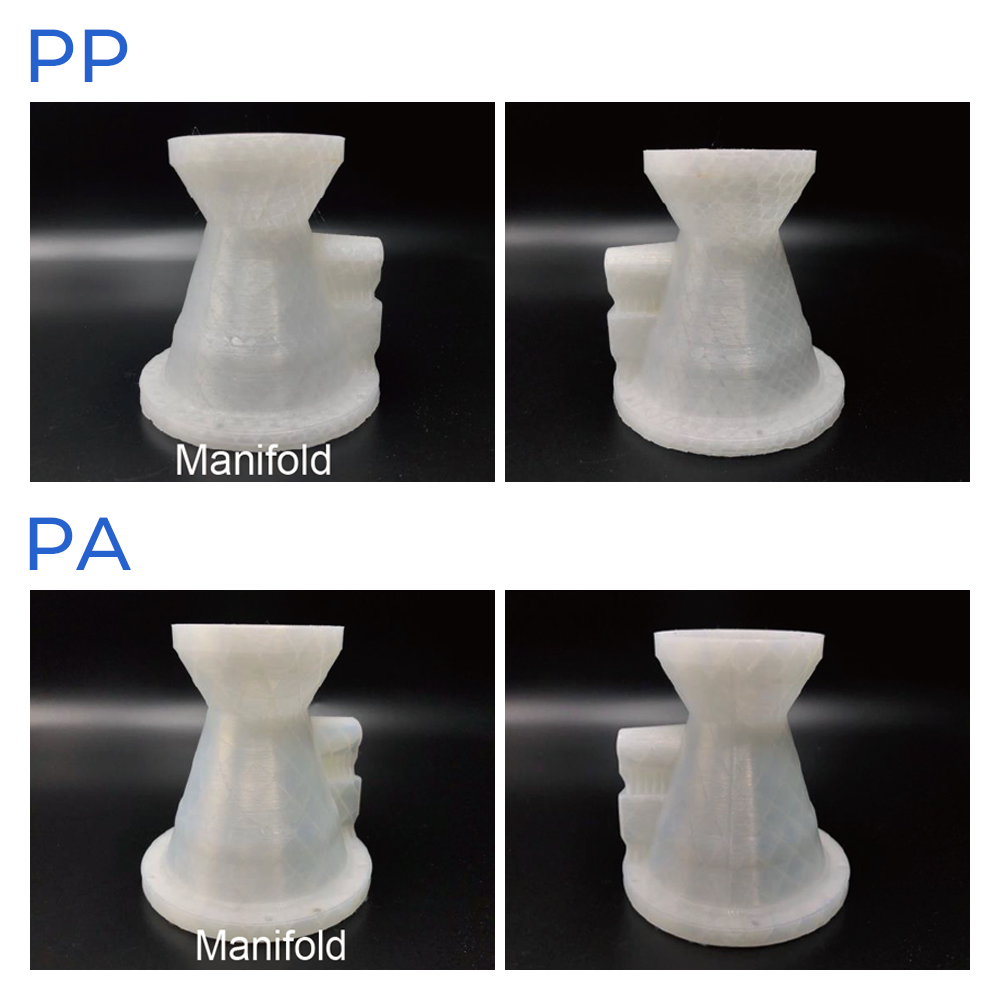

Another pain point businesses must grapple with when using traditional manufacturing is the limited selection of materials that can be used to verify product design prototypes, which greatly impacts the verification sufficiency and overall efficiency. To address this issue, Creality teamed up with AMTC to test more than 20 types of filaments and selected 14 that work best with the Sermoon D3 3D printer, including high-strength filaments ABS, ASA, PC, and wear-resistant filaments PA-CF, PET-CF. In fact, out of all Creality’s 3D printers, the Sermoon D3 is the model that supports the most filament types.

Specifically designed for optimal use with the Sermoon D3, the new co-developed HP-ULTRA filament series includes PLA and ABS. The new filament line is part of Creality’s “Better Filament Plan,” an initiative that aims to collaborate with market leaders to provide customers with high-quality filaments tailor-made for Creality 3D printers. HP-ULTRA has been fully tested by AMTC and Creality Lab on the Sermoon D3 3D printer, ensuring that users can achieve straightforward and accurate print quality without needing to manually configure the settings of the printer. Those who purchase the new Sermoon D3 package will receive a complimentary a 1kg spool of HP-ULTRA PLA.

At $2,499, Sermoon D3 is considerably affordable compared to professional 3D printers of a similar ilk. You can learn more or pre-order the Creality Sermoon D3 on the Creality Official Store. In addition, the Creality fully enclosed 3d printer family also includes the Sermoon V1 series, tailored for education, and the professional CR-5 Pro series. If you don’t want to wait for the Sermoon D3, the others are currently available.

About Creality

Founded in Shenzhen, Creality is a global pioneer in the 3D printing industry that focuses on the research, design and production of consumer and professional-grade 3D printers and 3D printing accessories. With user-centric philosophy, Creality has expanded its footprints across more than 192 countries and regions worldwide, introducing 3D printing concepts to homes, schools, workshops, factories and academic institutions, and driving digitalization in manufacturing, education, healthcare, architecture and beyond.

Committed to becoming a 3D printing evangelist, Creality continues gravitating to cutting-edge technology and bringing a premium experience for individual users and businesses. For more information: www.creality.com.