Last year, Creality released its Sprite direct extruders alongside the new S1 lineup. The new print head is a crucial aspect of the S1 series’ improvements on the original Ender 3 3D printers and has continued to impress us with every S1 we’ve reviewed.

But, as things go with Creality, all the details about the Sprite extruder aren’t crystal clear, with a lot of information either spread out or just not so obvious. Part of that is how the Sprite extruder actually has four variations, which can make purchasing the extruder as an aftermarket upgrade rather confusing.

If you’re buying the Ender 3 S1 Pro or buying the Sprite extruder directly from Creality, you’ll end up with what’s known as the Sprite Extruder Pro. We’re focusing on this version of the extruder for this article, but be aware that each of the other Creality S1-series’ included Sprite extruders differs slightly from the Sprite Extruder Pro. So, we’ll kick things off by going over those differences in the section below.

If you’re unsure what implications a feature has in performance or usability, be sure to read the corresponding sections about the Sprite Extruder Pro, where we go into more detail.

What is the Sprite Direct Extruder?

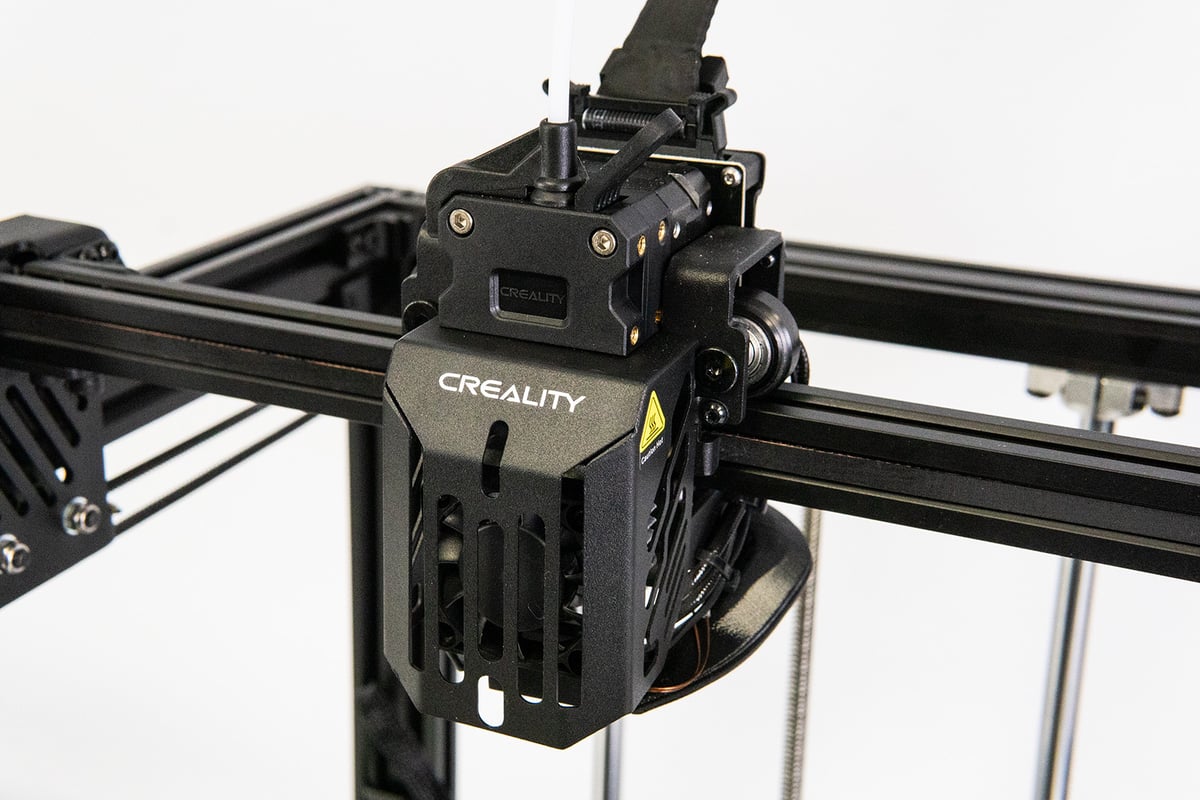

As the name suggests, the Spirte extruder is a direct extruder, meaning that the print head includes its stepper motor and drive gear. Direct extruders like the Sprite exert force closer to the hot end than Bowden extruders, allowing greater precision while printing. The tradeoff is that your X-axis is carrying added weight, and that can result in poorer print quality — especially when trying to print faster. But, direct extruders have become significantly lighter in recent years, largely solving problems with extra load in typical printing conditions. The Sprite is Creality’s take on a modern direct extruder such as this.

Sprite Extruder Variations

In typical Creality fashion, details surrounding the Sprite can get a little confusing. There is actually a different version of the Sprite extruder for each of the S1-series 3D printers. The differences are minor, so you don’t have to worry about differing internal components or quality. Among the Ender 3 S1s, there are two major differences between each version: the body material and the heat break.

As you can see in the table above, the body material affects the Sprite’s weight rather significantly. Though the higher 334 g is above what we would typically consider a lightweight extruder, it’s a fine weight for Cartesian 3D printers and isn’t likely to be your first bottleneck when printing at higher speeds.

Be especially mindful of what we’re calling the “Sprite Extruder Plus”. Though it has the Pro’s metal body, it has a Teflon throat tube that limits safe printing temperatures to 260 °C. Creality doesn’t help that confusing matter with its somewhat deceptive marketing of the extruder as a “full-metal” extruder (as opposed to “all-metal”) in the Ender 3 S1 Plus’ ad copy. It’s not. It’s just a metal body.

If you buy the Sprite extruder directly from Creality, only the Pro version is available; but some third-party retailers do sell the more basic Sprite extruders. Be sure to refer to the table above so you know what you’re getting.

Encore: Ender 5 S1 Sprite extruder

The final variation of the Sprite extruder is, at the time of writing, only available on the Ender 5 S1, and it’s sufficiently different that we thought to separate it entirely.

The Ender 5 S1’s Sprite extruder keeps the 25 mm pancake stepper with a 3.5:1 gearing ratio and dual gearing, and the breakout board with its flat cable connector, but changes most everything else about the print head.

Probably the most important difference is this Sprite’s larger heater block and nozzle, creating a larger melt zone to accommodate Creality’s goal of faster 250 mm/s printing with the Ender 5 S1. It’s also swapped out the small aluminum block heatsink for a good-sized corrugated heatsink introduced with Creality’s Ender 3 Neo series. Creality says it printed for 1,000 hours “clog-free” with this setup. Separating these two components is a titanium alloy heat break, making the Ender 5 S1’s Sprite the only version besides the Sprite Pro capable of printing at 300 °C.

Of course, with the larger parts, Creality has also altered the fans on this version of the Sprite. A beefy 5015 blower fan on the extruder’s back acts as the part fan, fixing a minor fan orientation issue with the other Sprite extruders and directing air through Creality’s “Urus” dual-channel air duct while the front fan pulls air into the heat sink.

Sprite Extruder Pro

The Sprite Extruder Pro is a competitively-priced print head at ~$81 – putting it in line with other aftermarket direct extruders. But, unless you already have the extruder’s required flat cable, you’ll want to pick up the Sprite Extruder Kit for ~$110. A little expensive compared to some other direct extruders, but still rather competitive.

If you’re getting the Sprite extruder to upgrade an older Ender 3 model, you probably don’t have this flat cable sitting around and will want to pick up the more expensive Sprite Extruder Pro Kit. The only reason to purchase a non-kit aftermarket Sprite Extruder Pro is if you’re upgrading one of the Ender 3 S1 printers with a PTFE Sprite (the low-heat variant).

Creality’s product listings don’t really make the difference between these versions obvious – the only change on each product’s page being the 3D printers listed under “Compatible Models” – but the kit version of the Sprite includes both the flat cable and the extruder’s mounting bracket for 20 mm extrusions. So, the latter price is really the upgrade cost. Nice to have the option to go cheaper if you do have what you need, at least.

300 °C Printing

With the Sprite Extruder Pro, you’re getting the heavier 334-gram version with a titanium heat break. Unlike the Sprite’s more basic versions, that means you’ll be able to print at 300 °C – unlocking exotic materials like nylon and PC.

Part cooling is handled by a typical 4010 part fan tilted at the front of the print head with a short duct directing air toward the nozzle. This fan setup, specifically its orientation, is our only real qualm with the Sprite extruder. Since it’s facing down, it sucks up the heated air above its print bed to cool extruded material. But, it’s still a small complaint. The part fan orientation is fairly common and we encountered no significant problems with part cooling – but it could be a problem if you’re pushing your print speed to its limits.

Aluminum Heat Sink

At first glance, you might think the Sprite’s aluminum heat sink isn’t the ideal heat dissipation setup. We’re happy to report that, despite a setup that doesn’t seem ideal, we’ve had no problems with heat creep over a lot of print time with the Sprite extruder.

Typically, you want to see lots of thin fins directly exposed to a fan that is pulling air through them to provide rapid cooling. The Sprite includes a fairly discrete aluminum block acting as the heat sink with fewer fins than we’d expect to provide effective cooling. The fins form a long, constrained channel that a single 4010 fan with a small vent pushes air through. It might not look like an ideal system, but it seems to work and keeps the Sprite as a tight single unit without too much metal or too many bulky fans weighing it down.

If you’re worried this heat sink isn’t up to the task, you could always grab Creality’s Sprite-compatible watercooling kit — which we can confidently say exists. Though we can’t speak to why.

Dual Gear

You won’t be able to see it from the outside but the Sprite extruder is dual-geared, meaning both the drive gear and idler – the parts that grip the filament – are toothed. Dual gearing is a common feature, especially in direct extruders like the Sprite, for the positive effect it has on filament control. With two gears, you’ll have a more reliable experience with tricky filaments like flexibles and have generally more precise control over filament.

High Torque

The challenge in creating a quality direct extruder is balancing print head weight and torque. To get the torque you need for reliable extrusion in a direct drive setup, you need a big stepper motor, but to eliminate artifacts on 3D prints, you need the print head to carry less weight, ideally by using a smaller stepper motor. That’s where gearing ratios come in.

With torque, the smaller the motor, the less there is. However, the use of a short gear train can address this. The Sprite uses a 25 mm long pancake stepper motor that’s on the lower side of torque. But, in combination with the extruder’s 3.5:1 gearing ratio, Creality says the Sprite can create an extrusion force of up to 80N. For 1.75 mm filament, that’s a generous amount more force than you’re likely to need.

Breakout Board

Rather than spread into an array of loose wires, the Sprite’s flat cable plugs into a breakout board on the back of the extruder. This has the unfortunate effect of making the Sprite Pro kit essential when installing the extruder as an upgrade, as you can’t easily swap in an alternative cable. But, the breakout board is an appreciated feature that helps make the extruder neatly organized.

Print head break-out boards are growing in popularity lately, and feature in upcoming printers from other well-known manufacturers like Prusa Research on the Original Prusa XL’s Nextruder. The appeal is, in part, due to how breakout boards simplify repairs. If you’ve ever replaced a thermistor on an Ender 3, you might be familiar with the annoying task of separating long wires from the bundle and detaching them from the mainboard. With a breakout board, the print head’s connections are all just a few millimeters and easily replaced without needing to disassemble any other part of the 3D printer or separate a longer wire coming from the mainboard. Handy.

License: The text of "Creality Sprite Extruder: Ender 3 S1 Deep Dive" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.