As the industrial 3D printing market becomes increasingly populated with hardware advancements from both newcomers and established 3D printer manufacturers, there’s been an increasing need for highly capable machines at an affordable price. CreatBot, a leader in low-cost industrial 3D printing, has continued to establish itself on the market by developing machines that provide clients with the most highly sought after features without the usual exorbitant price tag.

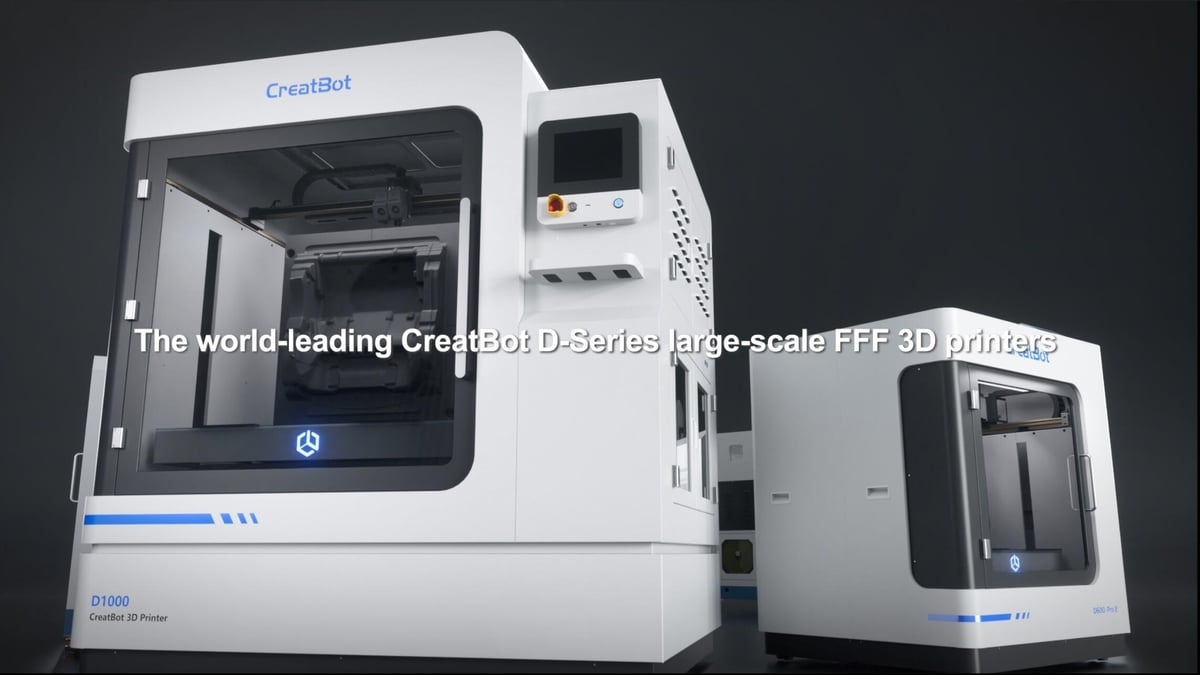

CreatBot saw success with its F1000 model, which has been on the industrial market for the last three years with more than 500 units installed worldwide. Based on customer feedback and technological updates, the manufacturer has returned with a new and improved model: the D1000. Together with the D600 series and other industrial-grade 3D printers that will soon hit the market, CreatBot is aiming to position itself as one of the world’s leading industrial FFF 3D printer manufacturers with the new D1000 and the rest of its D series portfolio.

Let’s learn more about the CreatBot D1000 3D printer.

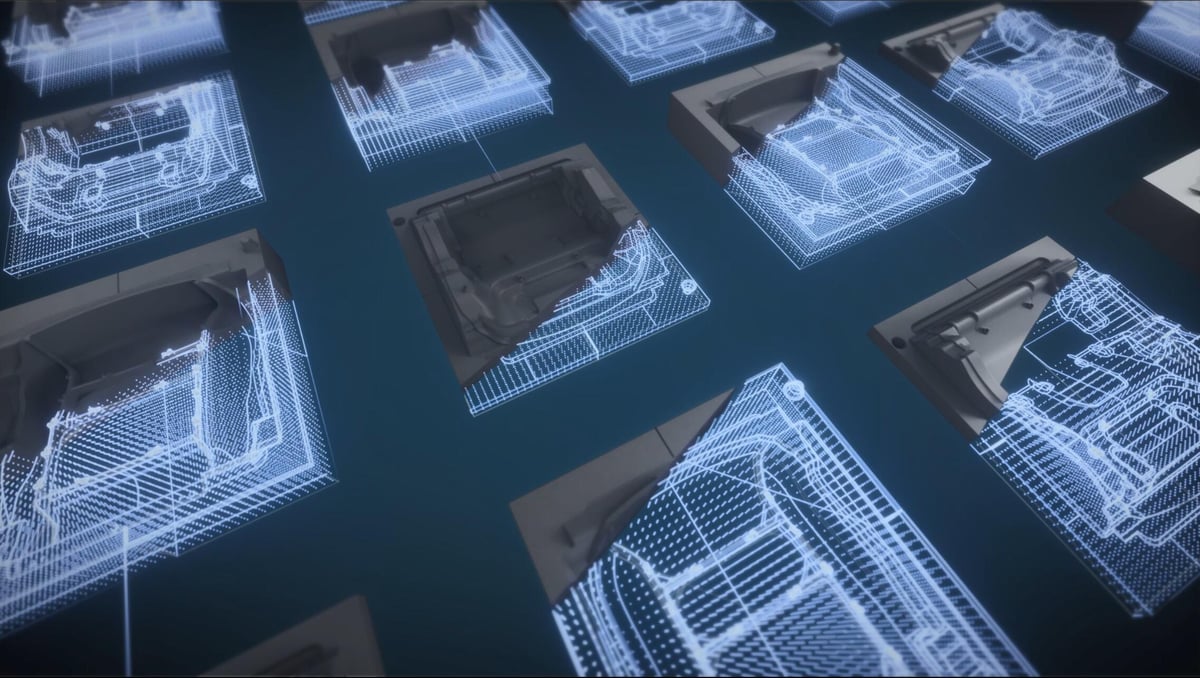

The D1000 model features a massive build volume of over 1000 x 1000 x 1000mm, making it is the perfect machine for creating large and full-size parts, prototype, tools, molds, jigs and even fixtures in-house. Within days you can have a fully functional high-quality prototype designed and 3D printed.

CreatBot doesn’t just print large objects, it also supports large rolls of filaments, including PLA, ABS, ASA, PC, Nylon, PA-CF. The company’s large-sized spools ensure that customers can print big models without worrying about having to replace the filament in the middle of a project. CreatBot D1000 prides itself on producing parts that meet the industrial standards, while also ensuring a high rate of repeatability for hassle-free printing. There’s a reason why the 3D printer manufacturer is trusted by global leaders in aerospace, automotive, defense, molding and casting, transportation, manufacturing, industrial components, arts design and props, education and research, equipment and machinery, function prototyping, pipes and tubes, and more.

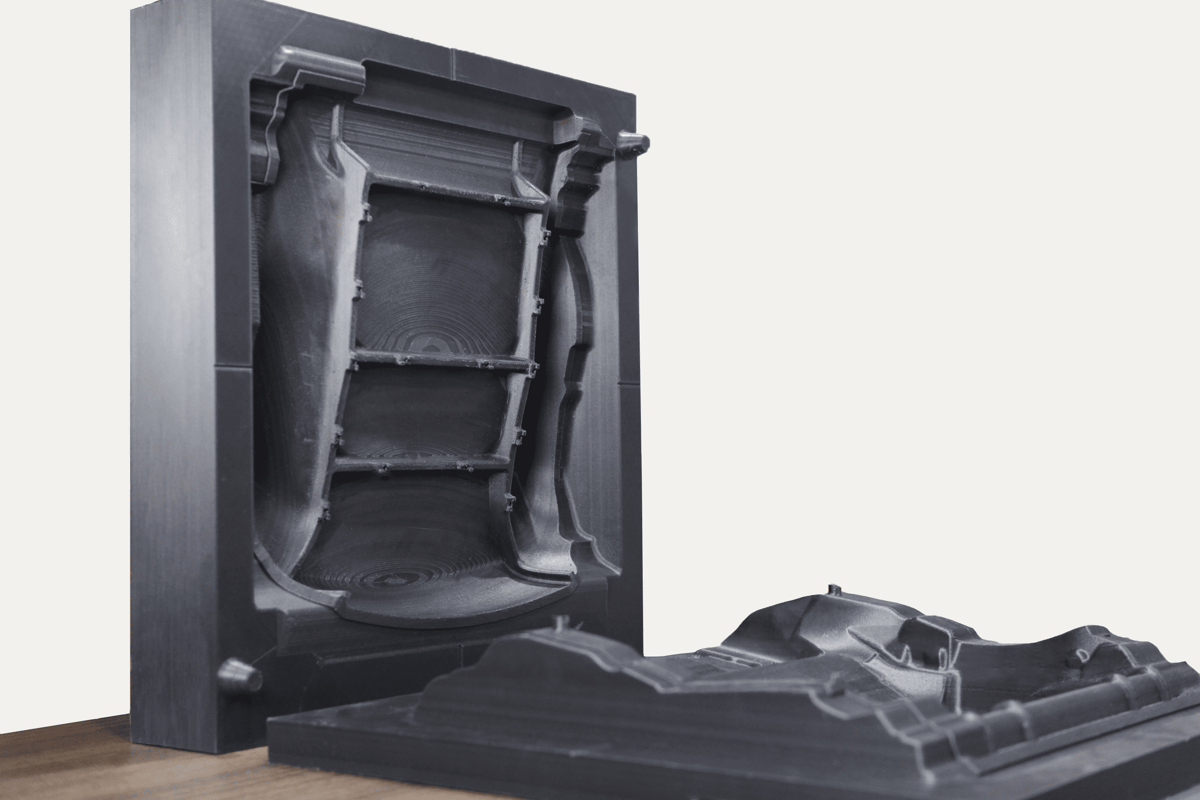

There are plenty of examples that showcase how companies have been leveraging the CreatBot D1000 3D printer for their own applications and needs. Faurecia, a global advanced automotive system engineering and equipment supplier, uses the CreatBot D1000 model to design and develop automotive seat molds that are widely used by leading car manufacturers like Audi, VW, NISSAN, and GM motors. The Bowl and lid are required withstand 100MPa, Using Nylon-carbon fiber materials for the production with 50% infill, the company was able to 3D print the bowl and lid of the seat while ensuring it could withstand 100MPa of stress. The prints were fully functional and managed to pass the strict testing regiment without a hitch.

CreatBot D1000 was created to make industrial 3d printing of large-scale objects, for both functional and prototyping purposes, as easy as possible. This new and improved industrial 3d printer is embedded with a new smart auto-rising dual extruder, enclosed heated chamber, automatic leveling system, and camera control that enables monitoring of large-scale print jobs.

Utilizing customer testing and feedback, CreatBot was able to develop an industrial 3D printer that can compete with the performance of more established, expensive brands on the market, but at a third of the price. This makes the CreatBot D1000 an ideal option for businesses that want to integrate 3D printing into its manufacturing or prototyping process without breaking the bank.

High-Strength Prototyping at a Large-Scale

Another benefit of the CreatBot D1000 is its compatibility with a wide-range of filaments beyond PLA and ABS. CreatBot offers advanced materials such as UltraPA-CF and PET-CF, providing functional performance to large-scale prints. With a large-sized nozzle and CreatBot’s advanced filament, customers can create a gigantic model with a high tensile strength of 80MPa and temperature resistance 150 ° C. This makes the D1000 is a terrific option for functional protype verification at a low cost.

Advanced Extruder System

There are several other features that help the D1000 standout among other low-cost industrial 3D printers. It is embedded with new smart auto-rising dual extruder hot-end kit that allows the nozzle temperature to reach up to 420 ℃. The specially developed alloy hot end can ensure that large models can be printed 24/7 without any problems. Moreover, the hot end can be replaced with a different sized one quickly and with ease. Thanks to this advanced extruder setup, the 3D printer can print large size engineering grade materials like ASA, ABS, PC, Nylon, Carbon Fiber, and more.

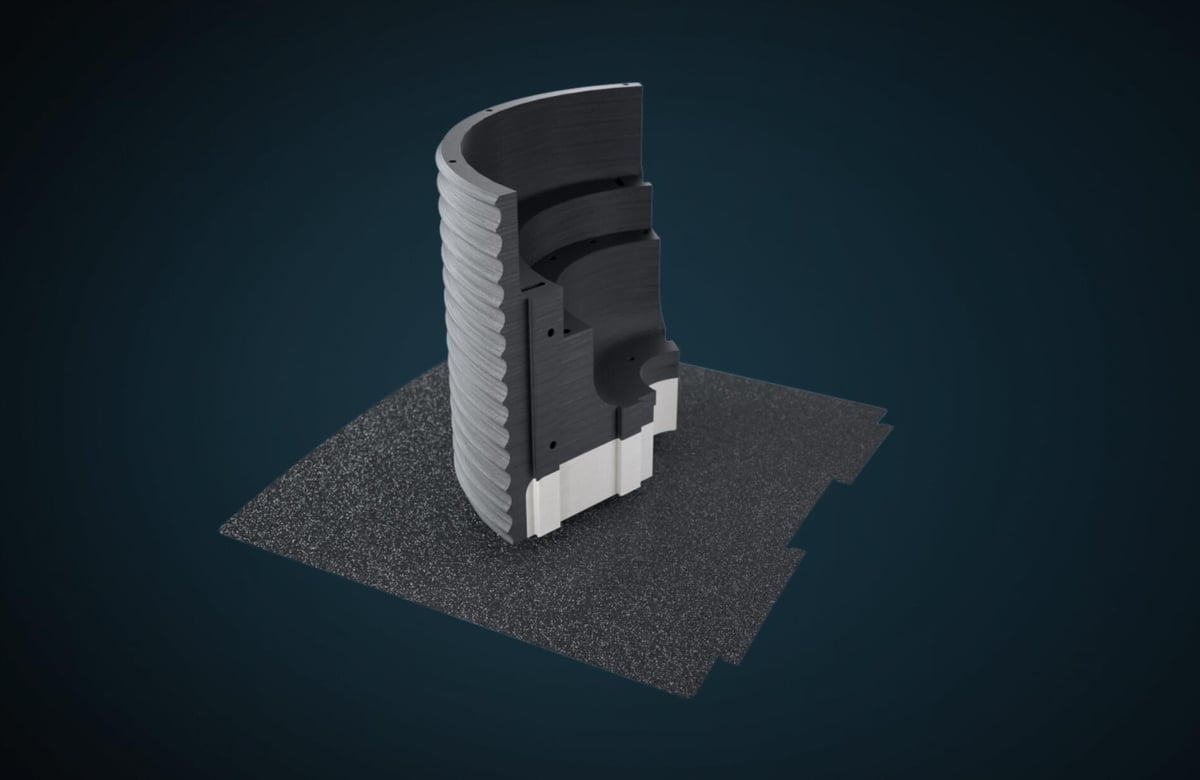

Magnetic Print Platform

CreatBot’s research and development team also helped devise the upgraded magnetic platform with a large size, easily removable platform and high temperature resistance exceeding 100 °C, enabling long-term use without demagnetization. For oversized models, it is easy to remove the print bed and detach the 3D printed objects quickly, while also ensuring that the bottom of the model is flat. Users can remove a 900 x 900mm model from the magnetic print bed in just one second.

Linear Rail and Servo Motors Design Ensures High-Performance Printing

With servo motors, the printer operates and responds to directions quickly and efficiently, while also significantly reducing heat and noise coming from the printer. The high-grade industrial design boasts ultra-high performance with high speed.

Hot Chamber + Filament Dry Room

The D1000 is equipped with a 60°C hot chamber that ensures print quality for high performance materials. The fully enclosed chamber can block all external conditions from impacting the quality of the printed part. This enclosed frame also aids in reducing noises, while at the same time providing a constant temperature and preventing deformation or print failure.

Auto Leveling Platform

This industrial 3D printer also leverages an auto-level platforming technology that maps out 100 points through the high precision servo probe. This platform leveling data is saved through the Z-axis intelligent compensation table height to ensure fully automatic leveling throughout the entire printing process.

HEPA Air Filter

Finally, the D1000 also promotes user safety with a high-grade HEPA air filter. The air filter system can adsorb impurities and gases that generated by printing special filament like ABS, Nylon, PC, creating a safer and cleaner printing environment for all.

If you’re interested in learning more about the CreatBot D1000 3D printer, you can visit the manufacturer’s website here.