When it comes to professional 3D printers, few manufacturers have managed to mend affordability and performance quite like CreatBot. The company’s portfolio ranges from massive FDM machines to 3D printers specially tailored for education or medical applications.

Out of this extensive product line, the CreatBot D600 Pro is one of the manufacturer’s most successful products. Now, the CreatBot team has decided to improve upon its substantial flagship 3D printer by creating the D600 Pro. This improved iteration was developed based on the original D600 model, released in 2019.

Like its predecessor, CreatBot D600 Pro is able to print incredibly large objects with high performance materials, making it ideal for an endless array of industrial applications, from prototyping to end-use production. Despite some similarities, there are several new features that put it above and beyond the original D600.

The biggest upgrades found in the CreatBot D600 includes state-of-the-art servo motors and newly developed extruders. Despite these notable improvements, CreatBot has managed to keep its latest machine in an affordable price range, especially in comparison to other large-scale 3D printers.

Let’s explore some of the features that make the CreatBot D600 a big bang for your buck.

Besides handling standard materials like PLA, ABS, and PETG with ease, the CreatBot D600 Pro is also compatible with engineering-grade materials, such as Carbon Fiber Nylon, Glass Fiber Nylon, PC, ASA, PVDF, and other high-performance filaments. Those looking for a professional industrial 3D printer with large-scale printing capabilities will be intrigued by what the CreatBot D600 Pro has to offer.

The D600 Pro is designed for industrial applications of all kinds, including prototyping, tooling, casting, as well as manufacturing end-use parts and other small-batch production needs.

CreatBot D600 Pro Boasts Big Print Volume and High-Performance Capabilities

Size is an important feature for a 3D printer that can take on industrial applications, and the D600 Pro satisfies this need with a massive 600 mm x 600 mm x 600 mm print volume. It’s also equipped with a fast-heating print bed that goes up to 100°C, dual extrusion capability, heated chamber that can maintain a consistent 70°C, and also a temperature-controlled filament chamber.

While the print volume of the D600 Pro is sufficient, the printer itself remains dimensionally compact, allowing for a snug fit in small workspaces, offices, or busy production floors. It’s delivered to customers fully assembled, so there’s no need to worry about where to assemble or position the 3D printer once it arrives.

CreatBot D600 Pro is one of the few industrial FDM machines on the market to offer such a commanding build space within a slender frame, creating an office-friendly footprint for those with limited space.

It’s commercial-grade features enables users to produce high detail models from traditionally tough-to-use materials, making it a system perfectly capable of producing high-quality prototypes, tooling, and end-use parts.

High-Temperature Dual Extruders Provide Filament Flexibility

CreatBot D600 Pro is equipped with 4th generation 1.75mm dual extruders and hotends. The left extruder features a 260°C hotend and the right extruder has a hot end capable of reaching 420°C. This wide range in temperature enables users to print with PLA, ABS, PC, Nylon, Carbon fiber, Flexible, ASA, PETG, and more engineering-grade materials. The right extruder hotend is made of martensitic steel, which is able to withstand extraordinary temperatures and print with high-performance filaments. The dual hotend is replaceable, providing flexibility and endless possibilities when it comes to selecting the right material for your application.

If you need proof of the D600 Pro’s professional capabilities, look no further than this automotive use case. CreatBot helped automotive enthusiast Bruce Warren beat his own racing speed record in his Cadillac CTS-V. His blistering 192 mph (309.3km/h) marked the new world record for a CTS-V or CTS-V Sedanstock with a stock blower. The CTS-V he used to beat the record was equipped with a 3D printed intake, designed by engineer Justin Tylor, that was produced using a CreatBot D600 Pro 3D printer.

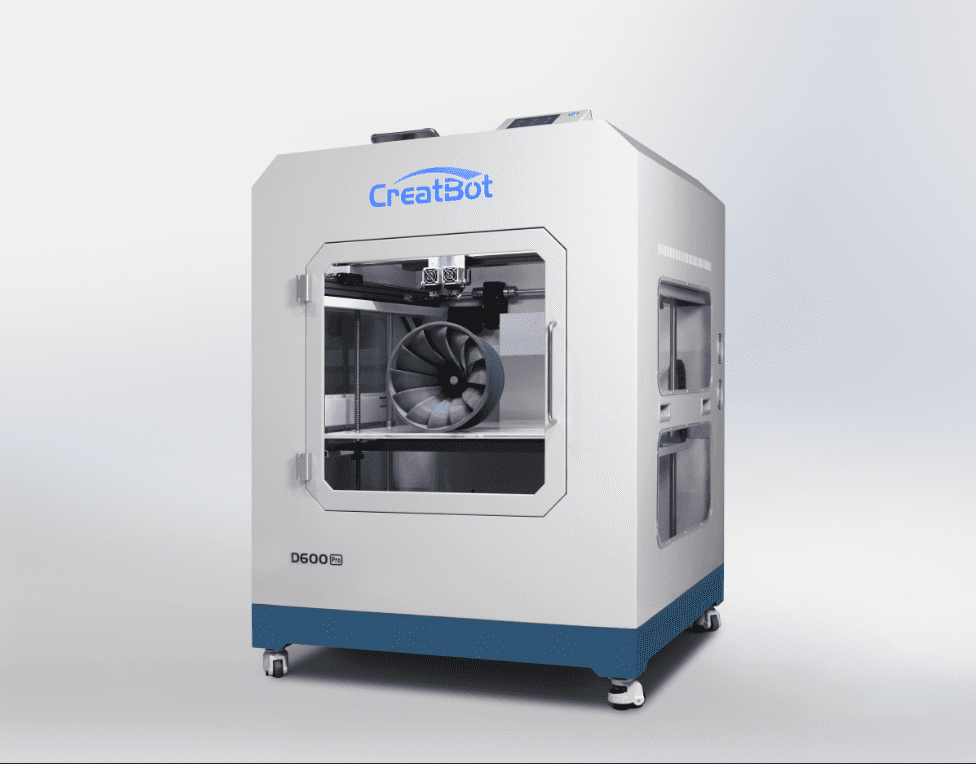

Here is a example of a model air intake part produced by the CreatBot D600 3D printer with Ultra Nylon-Alloy filament: