Creo computer aided design software by PTC is inching up against rivals Fusion 360 from Autodesk and Solidworks from Dassault Systèmes, especially with its latest trove of updates found in version 9 unveiled today.

In a word, Creo 9 is about speed. Core enhancements enable better designs in less time. The latest updates to the model tree to make it faster to structure, document, and understand design intent, and a new function for dividing surfaces improves analysis and product definition.

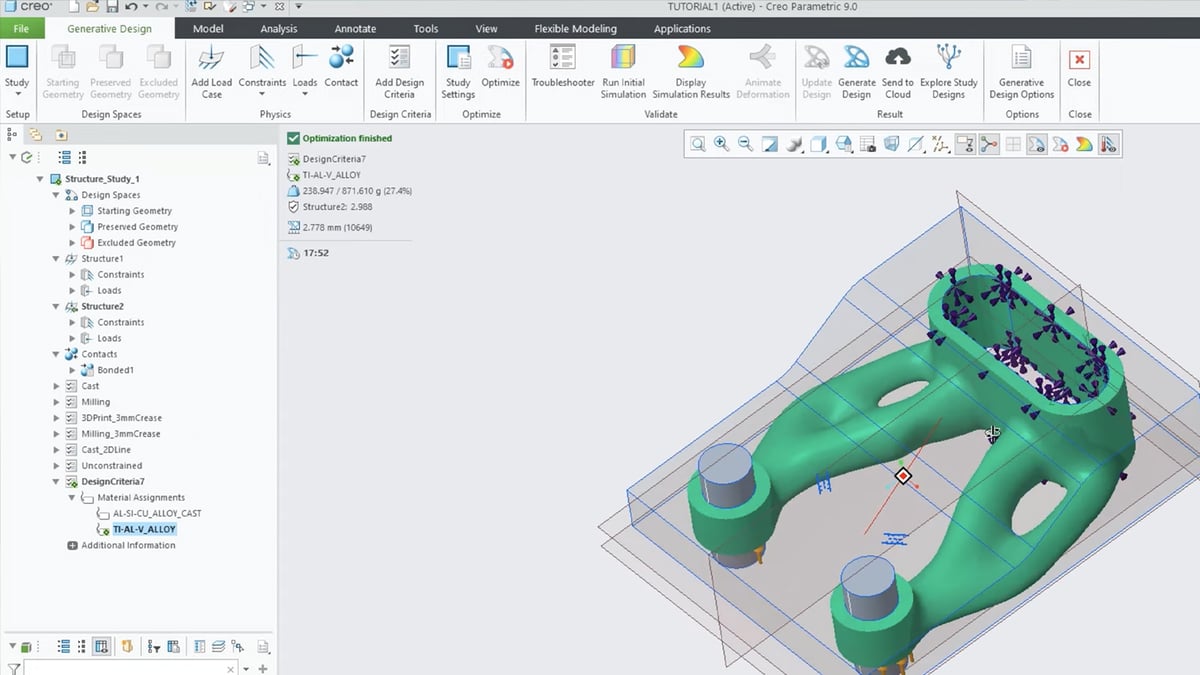

PTC also boosted the power of its simulation and generative design capabilities incorporating advanced multi-physics from Ansys into the Creo simulation portfolio. The applications already-solid generative design technology sports some new capabilities enabling you to define optimization studies with designed-in safety factors and natural frequency limits.

Creo 9 continues to grow its investment in model-based product design, especially in surface finishing and welds, which means you can include specialized downstream manufacturing information, such as iteration number or product specs, right on the model. This is a really handy tool for larger product shops boosting efficiency and communication.

Especially for use in 3D printing and additive manufacturing, Creo 9 delivers improved control over stochastic and formula-based lattices and better user-defined support structures.

PTC general manager in charge of Creo, Brian Thompson, give a nod to the user community for their role in identifying where Creo can improve.

“Creo 9 is an important release, and our customers’ feedback played a big part in making that happen,” says Thompson. “All these enhancements are about helping engineers get their best designs to market more quickly.”

One last expanded feature to note is the new Vision Field Analysis capability that enables engineers can analyze users’ line of sight and field of view when driving or using equipment. Other upgraded ergonomic tools help designers recognize the uniqueness of users – useful when coupled with additive manufacturing’s mass customization ability – while helping ensure products comply with safety, health, and workplace standards.

License: The text of "Creo Launches Version 9 of its CAD Software, the Best Yet" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.