In our rapidly changing world, you are likely to be integrating more unique features into your products than ever before. As such, you face the challenge of designing new products while being pushed to do more with less space. Amidst this process, one key design aspect that you have to account for is thermal management.

Thermal Management and Design Software

Thermal management techniques help you dissipate heat to control product temperature, leading to better product performance, reliability, safety and durability. At the core of every thermal management system is a heat exchanger. These devices transfer thermal energy, making them vital in aerospace, automotive, and electronic systems.

With the right tools, you can develop advanced and innovative heat exchanger designs to meet increasing thermal management requirements. These designs can incorporate new geometries, such as complex lattice structures, which can be produced using additive manufacturing.

Additive manufacturing offers significantly greater design freedom than traditional manufacturing methods.

Although additive manufacturing is radically changing our approach to traditional thermal management design problems, and revealing new solutions for solving them, we remain limited by our design software. Traditional software was created to support traditional manufacturing. However, to take full advantage of the design freedom associated with additive manufacturing, you must leverage advanced design software built for AM.

What Should You Look For in Your Design Software?

Choosing the right engineering design software helps you properly incorporate performance and functional requirements for thermal management early in the design process. Modern design software and advanced computational power ensures that heat exchanger designs can take advantage of additive manufacturing.

Implicit Modeling

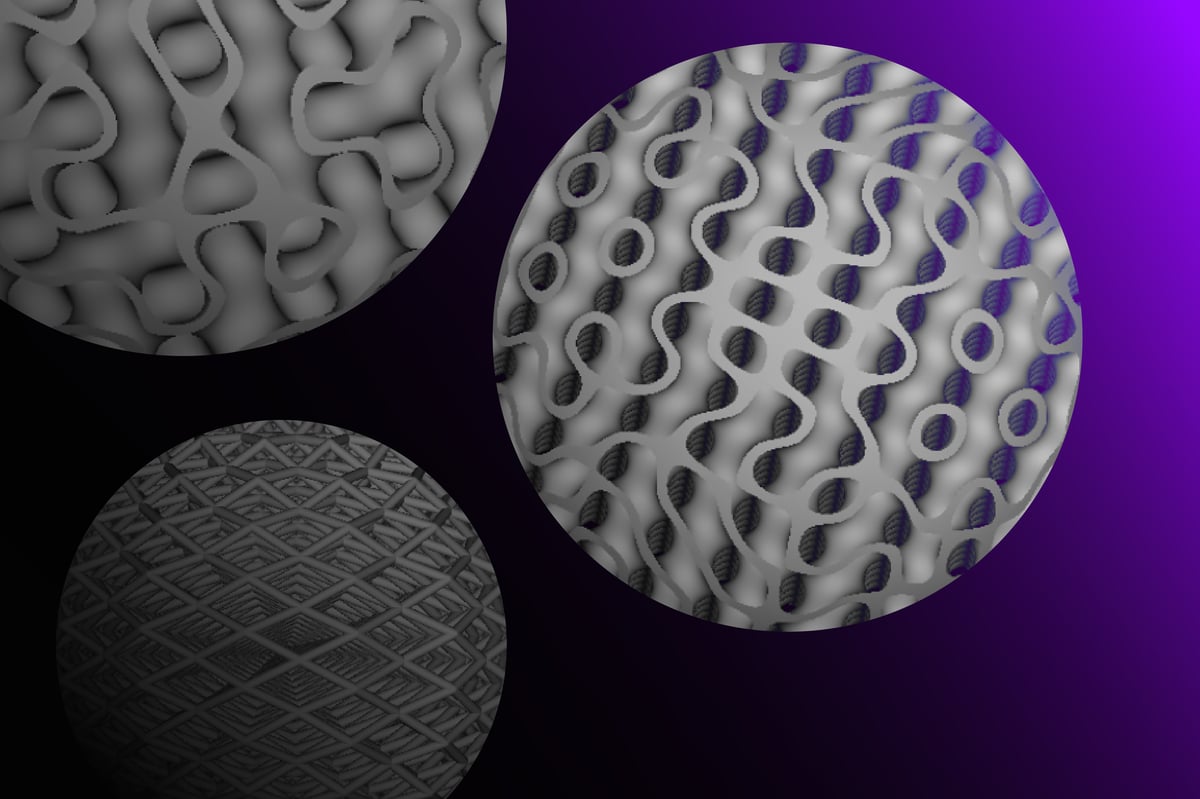

Traditional design software cannot handle the complexity of advanced geometries for additive manufacturing. Developing innovative product designs is a significant challenge for engineers that rely on manual processes. Through implicit modeling, you now have access to innovative and optimized design opportunities for thermal management.

Implicit modeling, at its core, is new modeling technology that uses a single mathematical equation to represent the geometry of a 3D object, instead of multiple equations that represent just its surface. This means you can easily create heat exchanger designs that incorporate complex geometries, such as lattice structures, shells of variable thicknesses, and smooth blends or filets. These unique geometries and complex design operations frequently break models or are impossible to create in traditional software solutions.

You need software that can handle these complex designs. Fortunately, implicit modeling ensures that modeling operations never fail and models never break.

Field-Driven Design

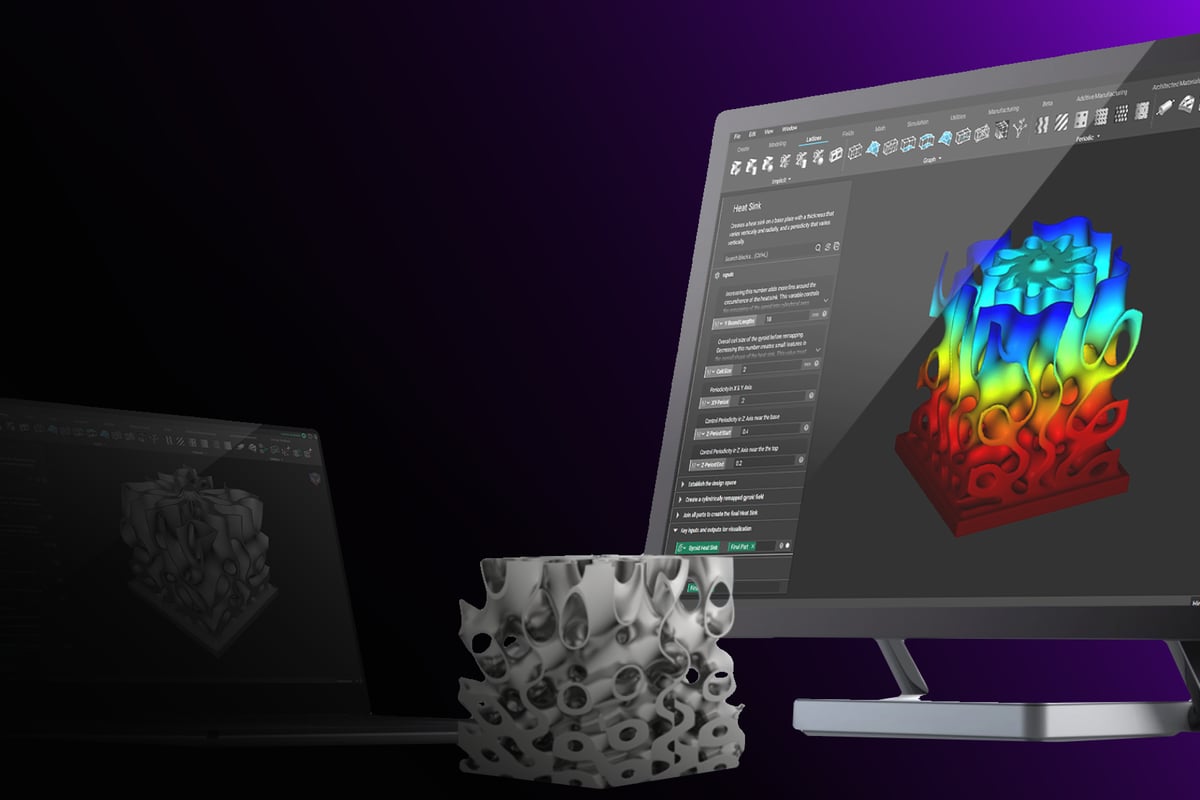

Field-driven design gives you a top-down generative design process to develop high-performing thermal management designs. In simple terms, if implicit modeling gives you an avenue to create complex designs, then field-driven design gives you a way to control them in every point in space. You can use data, simulation results, mathematical formulas, or existing geometry to develop data-driven designs.

You can control key design parameters using Computational Fluid Dynamics (CFD) fields or thermal data. These implementations help you create generative design workflows through an iterative process of geometry generation and simulation.

Reusable Workflows

nTopology’s advanced design software allows you to take advantage of reusable workflows, which can be packaged as custom blocks. A modular approach to design automation can improve design and manufacturing processes.

Reusable workflows allow you to accelerate design iterations, test new ideas quickly, and to automate processes like Design of Experiments.

Choosing the Right Software

You do not have to rely on outdated engineering design software to design advanced heat exchangers. nTopology empowers you to embrace additive manufacturing and develop next-generation heat exchanger designs.

nTopology was built from the ground up with additive manufacturing in mind. The software’s core technologies enable you to adequately address thermal management design considerations and take advantage of the design freedom of additive manufacturing.

Are you looking for more information on leveraging thermal management in your products and processes? Download nTopology’s comprehensive Thermal Management guide here.