Desktop Metal, a US-based metal 3D printing manufacturer, is closing the gap between its Studio System, designed mainly for office use, and the Production System, which is meant for high-volume production of metal parts.

Claiming to offer the “most cost-effective solution in the industry,” the Shop System utilizes a single-pass print engine and introduces a revised high-quality binder jetting technology. The manufacturer claims the Shop System “can eliminate many of the constraints previously seen with traditional manufacturing methods like CNC machining and tap into new opportunities to reduce their costs and increase revenue.”

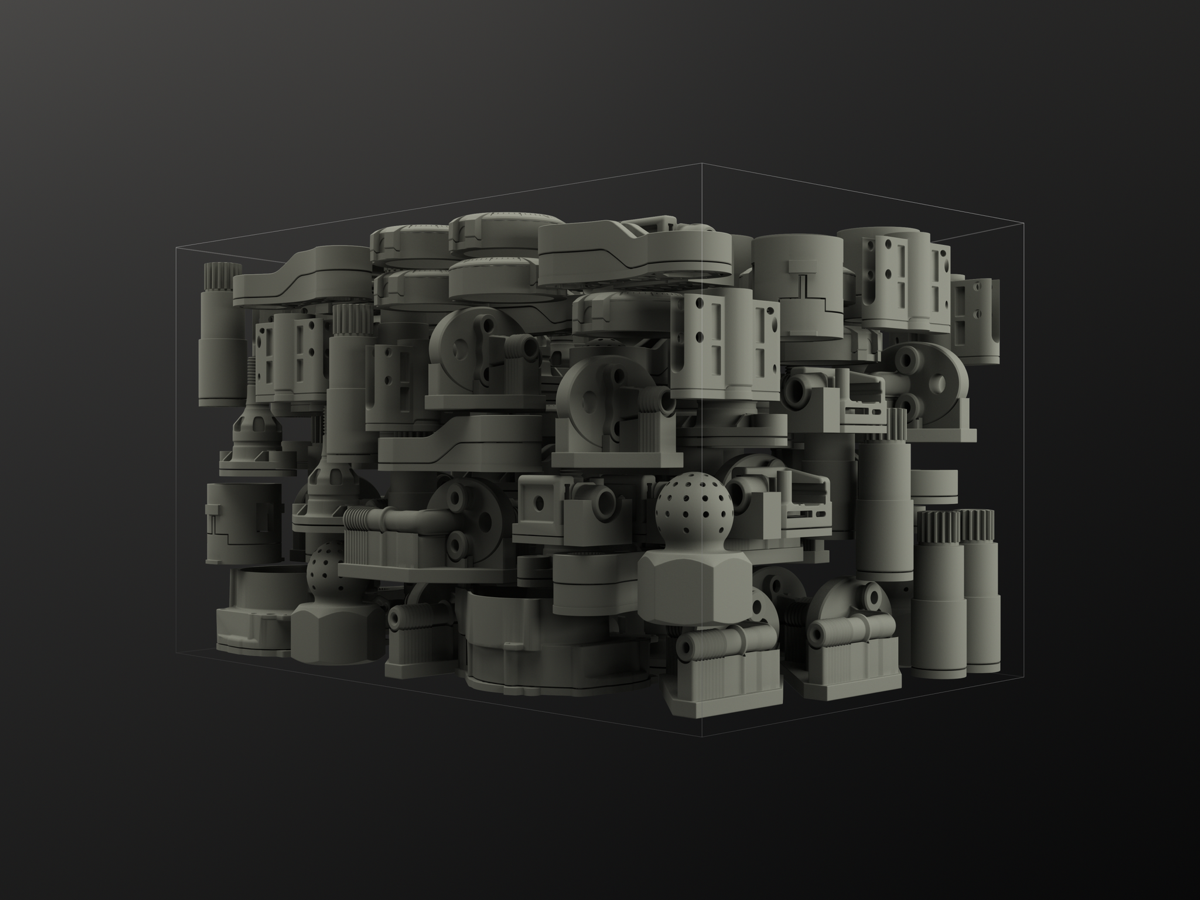

The system consists of the printer, a powder station, and also a furnace. It comes in four build volume configurations (4L, 8L, 12L, and 16L). Starting at a build volume of 350 x 220 x 50 mm with the 4L, the largest build volume offered is 350 x 220 x 200 mm for the 16L.

Prices start at $150,000.

According to the manufacturer, the machine can print batches of parts every six to 12 hours, which adds up to 70 kg of steel per day. Thanks to its binder jetting technology, prints are fully supported in their powder bed and feature hand-removable sintering setters.

Desktop Metal claims that with a spot size of 16 microns per drop, 1600 native single pass DPI and distributing up to 670 million drops per second, the Shop System is the highest resolution single-pass binder jetting printing system on the market.

Ric Fulop, CEO and co-founder, says: “Our current technology has significantly disrupted low- and high-volume production in metal manufacturing, yet there was still a real need for a robust solution that also captures mid-volume production and enables affordable, reliable and flexible batch production of complex parts for machine shops. For the first time with the Shop System, machine shops will be able to make that a reality.”

You find more information on the manufacturer’s website.

(Source: Desktop Metal)

License: The text of "Desktop Metal Launches Batch Production “Shop System” for Metal Workshops" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.