Throughout the week, the entire 3D printing industry is gathered in Frankfurt for Formnext 2018, perhaps the largest additive manufacturing conference and trade show on the planet. While the innovation on the floor is spread across different technologies and market segments, we weren’t surprised to find that metal 3D printing is again one of the major focal points of this year’s event.

On the very first day of Formnext, the Massachusetts startup Desktop Metal kicked things off by announcing that it was prepared to install the Production System for its first customer – an undisclosed Fortune 500 company – at the beginning of 2019. After releasing the desktop-sized Studio System to the world, the company has been diligently working to enhance the capabilities of its highly anticipated mass production metal 3D printer.

Desktop Metal states that its Production System is poised to be “the world’s fastest metal printer,” and will also deliver the lowest cost per part with the highest capacity compared to any other metal 3D printer on the market. To prove this claim, the startup headed to Germany to share a number of new features that have been integrated into the Production System.

“We are excited to provide the international engineering and design community with deeper insights into the power of the Production System with updated innovations and an extensive display of metal parts to be publicly shown for the first time this week,” said Ric Fulop, CEO and co-founder of Desktop Metal. “As we continue to expand our list of global customers and partners, companies that are turning to the game-changing technology available with the Production System, and installations set to begin rolling out in the coming months, Desktop Metal is looking to further shift the industry beyond prototyping to now include full scale metal manufacturing.”

Desktop Metal Furthers Development of Production System Metal 3D Printer

While it was initially introduced around the same time as the Studio System, Desktop Metal has improved nearly every aspect of the Production System, making it faster and more capable of mass producing high-quality metal parts. This 3D printer utilizes Single Pass Jetting technology, making it up to 100 times faster than any quad-laser metal printers and over 4 times faster than alternative binder jetting systems.

During the trade show, Desktop Metal shared a list of advancements that aim to expand the technology and the capacity of the Production System. For starters, the accelerated print speed has been increased to 12,000 cm3 per hour, making it the fastest metal 3D printer on the market. The startup has also increased the build volume to 750 x 330 x 250 mm, a whopping 225 percent improvement over the initial system.

Aside from the print speed and build volume, Desktop Metal has also renovated the inner workings of its metal 3D printing system. The new and improved Production System is equipped with two full-width print bars, advanced powder spreaders and an anti-ballistic system that will help spread the powder across the build chamber and print in a single quick pass. With this enhancement, the manufacturer believes that the Production System will have the “most sophisticated single pass inkjet printhead ever installed in a binder jet system.”

The most recent version of the Production System will utilize 32,768 piezo inkjet nozzles, enabling the broadest range of binder chemistries to print an array of metals at a rate of three billion drops per second. In other words, this metal 3D printing system will be capable of printing more than 60 kilograms of metal parts per hour. Compatible metal materials include tool steels, titanium, low alloy steels, and aluminum.

Desktop Metal states that the Production System will be the first binder jet system with an industrial inert environment, which means it will provide gas recycling and solvent recovery. This will make it possible to safely print reactive metal materials in the mass production setting.

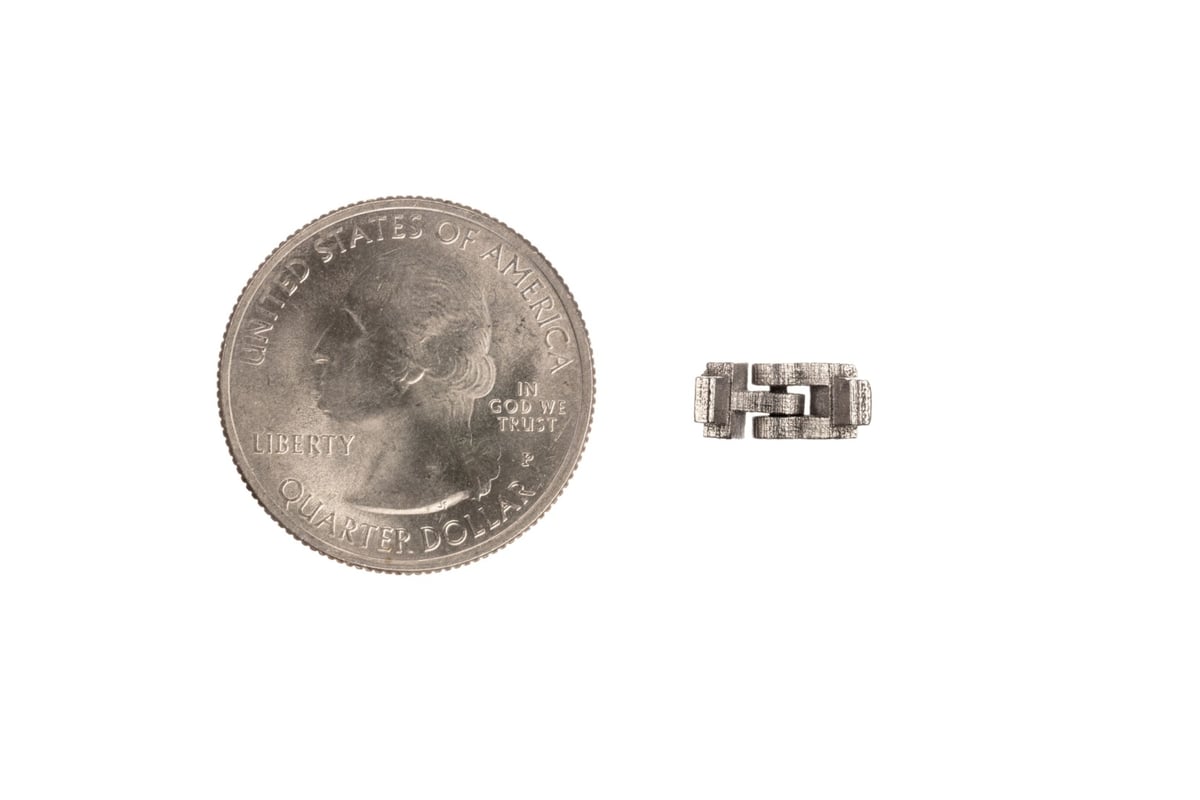

Throughout the remainder of Formnext 2018, Desktop Metal will be showing off a number of intricate parts produced with the Production System. So, if you’re in Frankfurt this week, you can check them out in Hall 3.0 – booth C10.

Source: Press Release

License: The text of "Desktop Metal Unveils Upgraded Production System at Formnext 2018" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.