There are hundreds of uses for 3D printing, but a quirkier one may be to do some knitting for you. In a recently published paper, Mark Beecroft, a senior lecturer at the Manchester Metropolitan University School of Art, explored 3D printed knit-based structures in a process he calls ‘digital interlooping’.

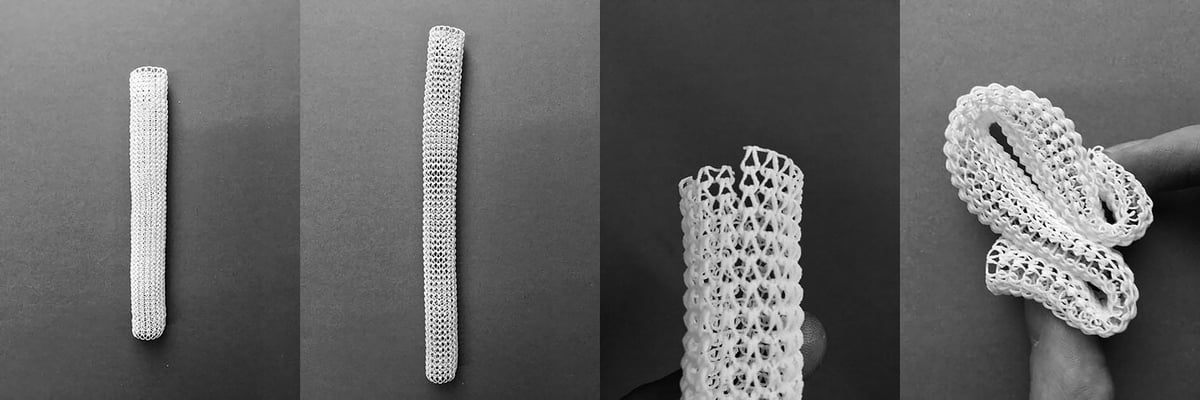

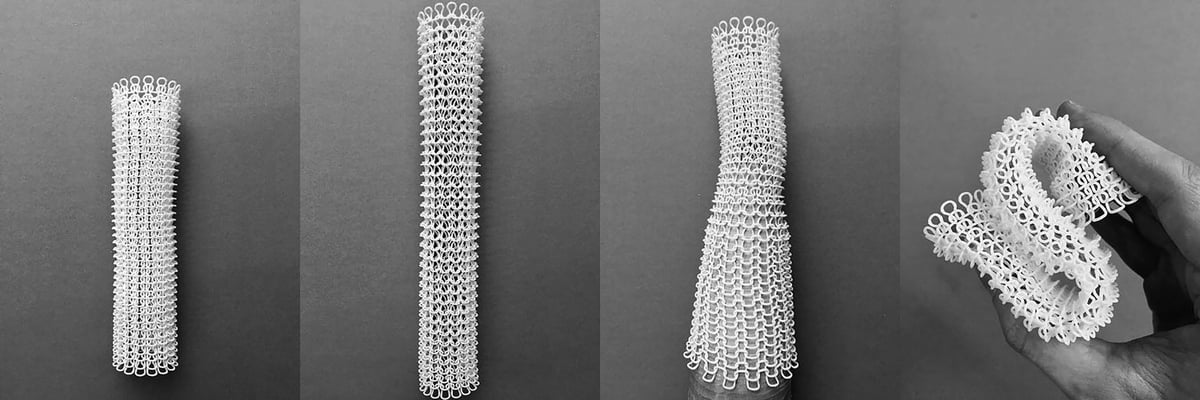

The paper shows that selective laser sintering (SLS) can create tubular knit-based structures using nylon (PA12) powder. The structures were continuously printed on an EOS Formiga P110.

No supports were needed and the resulting prints provide good flexibility, good mechanical properties and high levels of detail.

Beecroft says there is a potential future development and application of these pieces in apparel-related industries.

Testing the 3D Printed Structures

Previous 3D printed knitted structure research involved non-continuous printing methods and linked geometries. Beecroft’s work addresses this ‘gap’ in the literature. He believes his method offers “the opportunity for a new method of textile production.”

Currently, knit’s inherent properties are “underdeveloped in the testing of 3D printed structures.” To test these properties of stretch and flexibility, Beecroft compressed, extended, broke and folded the structures.

Although still in the speculative research stage, this work could be used in future technical textiles sectors such as sportswear and healthcare.

Beecroft will be continuing his research to test the durability of printed structures in controlled laboratory environments. This will involve testing the strength, elongation and load to the breaking point.

You can learn more about Beecroft’s work in his paper entitled: “Digital interlooping: 3D printing of weft-knitted textile-based tubular structures using selective laser sintering of nylon powder“.

License: The text of "Digital Interlooping: 3D Printing with SLS to Create Knitted Structures" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.