Auto-bed leveling (or tramming) has been an extremely popular feature in modern 3D printing for quite some time. It provides peace of mind when it comes to making sure that the extrusion system is correctly aligned to the build surface, allowing constant flow and print quality. On top of that, it saves the user time and frustration that can stem from manual bed leveling.

Nowadays, many types of Z probe-based bed leveling sensors are available on the desktop 3D printer market, including capacitive sensors, inductive sensors, and physical-hall sensors (BLTouch/3Dtouch).

However, these various Z probe technologies come with a few limitations themselves. For instance, inductive sensors only work on metallic surfaces, physical-hall sensors don’t provide great repeatability and are not very reactive, and capacitive sensors need to be recalibrated each time you change your build surface or hotend.

Created for all practical 3D printer purposes, the Horizon, developed by Dyze Design, transforms your nozzle into a very sensible force sensor. With this next-generation attachment, the Z motors are halted the instant your nozzle touches the bed. This enables very accurate Z homing of your bed without any risk of damaging your 3D printer. As a multi-faceted upgrade, Horizon can be used as a basic Z-axis end stop switch or extend its capabilities to auto-bed leveling features via 3D printer firmware logic.

“The Horizon, compared to other types of bed sensors on the market, is based on strain gauge technology, which measures the effect of external forces on an object. Doing so, it’s not limited by the type of surface you are using and doesn’t need recalibration of the Z-Offset each time you modify a part of your printer. And to top it off, because it’s sensing the force applied to it, the Horizon can be used for bed tramming but also for security and collision detection. In fact, your nozzle becomes you Z limit switch and your ABL sensor,” said Simon Duchaine, Chief Commercial Officer at Dyze Design.

Horizon also enables the Z-Offset to be automatically adjusted. There’s no need to update the firmware again if you somehow change the form factor of your hotend or nozzle. Finally, it’s also possible to level the 3D printer bed even when the nozzle is hot. It is convenient for thermal expansion, because there are no solid plastics in the Horizon that could disrupt the calibration.

The Horizon is mounted right in-between the carriage and the extruder or the hotend in a Bowden setup, so you’re not losing any space on your X-axis, as you would with most other sensors mounted beside your print head.

“It’s worth noting that the Horizon is providing detection in a more precise and repeatable way than any non-contact sensors, allow more clearance around your extruder because it is mounted directly on the carriage and doesn’t need any calibration after a component change (extruder, hotend, nozzles, bed surface) “ Duchaine added.

Horizon is also compatible with most popular extruders on the market, such as the Bondtech BMG and E3D Titan, as well as all common 3D printer firmwares like Marlin, RepRap Firmware and Klipper.

The Horizon is now available for purchase at the price of USD $96.75 or CA$130. You can buy it online on the Dyze Design website.

About Dyze Design

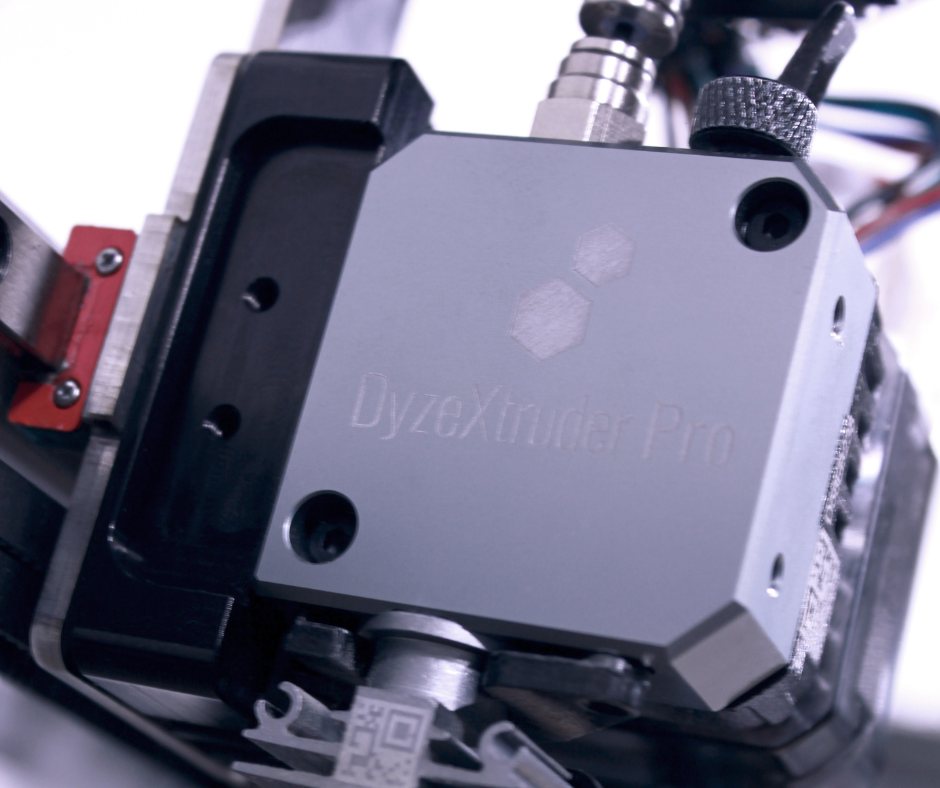

Dyze Design has been in the 3D printing industry since 2015 developing and manufacturing cutting-edge high performance, reliable, and innovative extrusion systems and 3D printer components for professional, industrial and large-scale 3d printers. They are renowned for their Typhoon™ high-flow extruder, Pulsar™ pellet extruder, DyzeXtruder GT and DyzeXtruder Pro extruder line, their SENTINEL™ filament detector or Tungsten Carbide Nozzles. Today, many 3D printer brands such as Roboze, Sharebot, Blackbelt, Dynamical 3D, Aon3d, Trideo, 3DPlatform, Filament Innovations, Mark One and Cincinnati have chosen their hotends, extruders, and nozzles as OEM parts for their industrial or high-end printers.