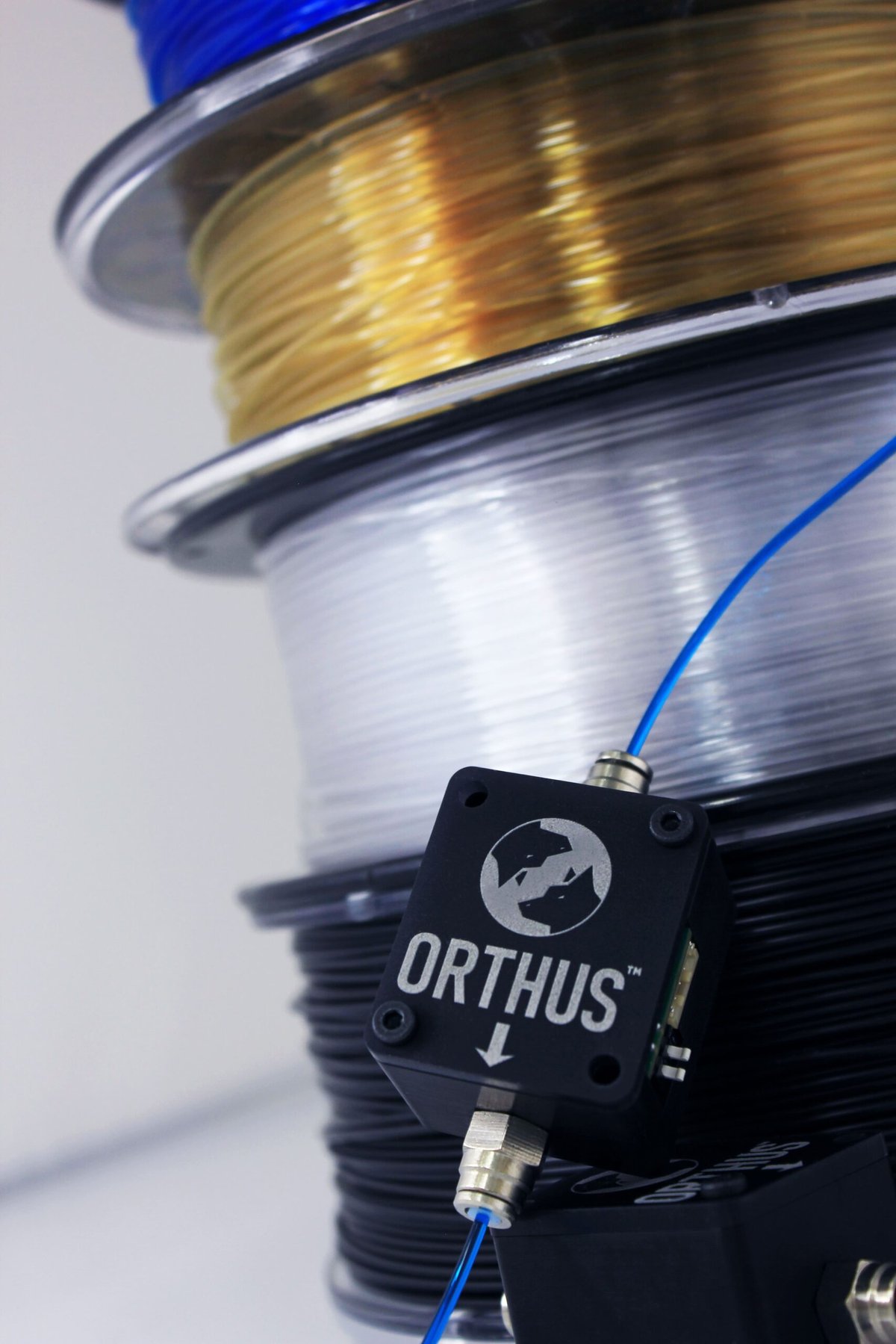

Dyze Design, a Canadian manufacturer of high-performance extrusion systems and components for professional and industrial 3D printers, has officially released its new filament monitor, Orthus, an ultra-precise filament monitoring sensor that enables instantaneous detection of both filament runout and jams.

Nowadays, filament detectors are commonly found in desktop 3D printers. Most machines on the market are now equipped with some kind of filament sensing systems to ensure more seamless, hassle-free operation, especially for prints that take several hours to complete. However, some of those built-in filament detectors are limited by the type of filament they can detect (such as clear filament). Some sensors can detect a runout, but not whether there’s a jam or clog in the extrusion system.

“The polymer industry is moving really fast. More and more new filament types are available each week and we realized that optical sensing technology is not able to keep up. And it’s hard to maintain” says Philippe Carrier, Dyze Design’s Chief Technology Officer. “It’s the problem we start seeing with our own filament presence sensor, the Sentinel™.”

In 2016, Dyze Design released the Sentinel on Kickstarter. This was one of the first filament sensors on the market, which enabled 3D printers to detect the end of a filament spool and effectively pause the print to allow the user to change the filament and continue operation.

“Having a bit of history with filament detectors, we learned that hassle-free printing also is not only a matter of detecting a runout, it’s also important to catch any problems in the extruder, like a jam or a clog.” says Philippe. “Orthus is not some kind of upgraded version of the Sentinel to detect a larger spectrum of filament type. It’s a brand-new technology that detects both filament runout and jam. And the magic with Orthus is that detection is instantaneous. There’s no buffer or delays.”

Orthus is one of the most precise filament detectors on the market. With a standard resolution of 9µm, it can detect and pause your print almost instantly. On top of that, you can manually adjust the sensitivity of the detector. The physical switch lets you choose between a resolution of 9µm, 148µm or 1,229mm, more than enough to ensure compatibility with any type of filament.

Orthus also works with both 2.85 mm or 1.75 mm filament diameters – not to mention a wide range of filament types. It is designed to work with all the filament types available on the market, such as PLA, TPU, TPE, PVA, PC, PETG, NYLON, PEEK, and PEI, just to name a few.

“Being an OEM for more than 25 printer manufacturers and having a lot of customers in industrial fields, it was really important for us to design a product that would not only work with actual but also upcoming polymers.” says Dyze CTO. “Orthus provides instant detection for all filaments: flexible, transparent, reinforced or filled filaments, you name it. And we know for sure that it won’t be obsolete in a year or two,” adds Philippe.

This new filament monitoring sensor is compatible with all open source firmware, including Marlin, Repetier, RepRap firmware, and others. It’s designed to seamlessly work a majority of desktop FDM 3D printers, and can be easily mounted onto the frame with just two screws.

On October 8, 2022, Orthus will be available for purchase at the price of CA$125. You can buy it online on the Dyze Design website.

About Dyze Design

Dyze Design has been in the 3D printing industry since 2015 developing and manufacturing cutting-edge high performance, reliable, and innovative extrusion systems and 3D printer components for professional, industrial and large-scale 3d printers. They are renowned for their Typhoon high-flow extruder, Pulsar pellet extruder, DyzeXtruder GT and DyzeXtruder Pro extruder line, their SENTINEL filament detector or Tungsten Carbide Nozzles. Today, many 3D printer brands such as Roboze, Sharebot, Blackbelt, Dynamical 3D, Aon3d, Trideo, 3DPlatform, Filament Innovations, Mark One and Cincinnati have chosen their hotends, extruders, and nozzles as OEM parts for their industrial or high-end printers.