Dyze Design has launched the Aurora, an industrial motion I/O controller poised to redefine professional and industrial 3D printing.

Featuring real-time data logging, dual-stage position feedback, and advanced cloud-based analytics, the Aurora helps users optimize production processes, minimize errors, and make data-driven decisions – and with its modular design, it adapts seamlessly to a wide range of industrial 3D printing applications.

Advanced Capabilities for Optimized Performance

The Aurora arrives with features designed to improve all aspects of professional and industrial 3D printing.

Real-time data logging, for example, enables users to monitor print progress, analyze outcomes, and learn from past results to facilitate continuous improvement during production processes.

Its dual-stage position feedback system ensures exceptional motor precision – and allows for on-the-spot corrections that boost accuracy and reliability. The controller’s advanced reactive motion planning system enables automated adjustments, such as speed changes or pauses, ensuring print stability – even under dynamic conditions.

Meanwhile, cloud-based analysis tools provide detailed reports post-print, enabling users to evaluate part quality, identify issues, and implement improvements for future production. The Aurora also features seamless integration with Dyze Design’s product portfolio, like the Orthus filament sensor, which detects potential inconsistencies in flow rate with no need for calibration.

By leveraging the Aurora’s advanced process data visualization functionality, users can view 3D models (digital twins) of printed parts with color gradients, check and validate a part’s accuracy with a single click, and access sensors’ data as a model is analyzed.

Additional features like multi-heater tools management, pressure compensation, auto bed calibration for optimal adhesion, and switchless homing further enhance performance, making the Aurora a comprehensive solution for professional 3D printing environments.

Cutting-Edge Integration and Customization

Aurora offers a highly modular and customizable platform, supporting up to 15 motors, both generic stepper motors and Dyze Design’s own Servo Motors, and 64 external devices. This flexibility allows users to tailor the controller to meet their specific needs, while over-the-air updates help them ensure their systems remain current and manage new features.

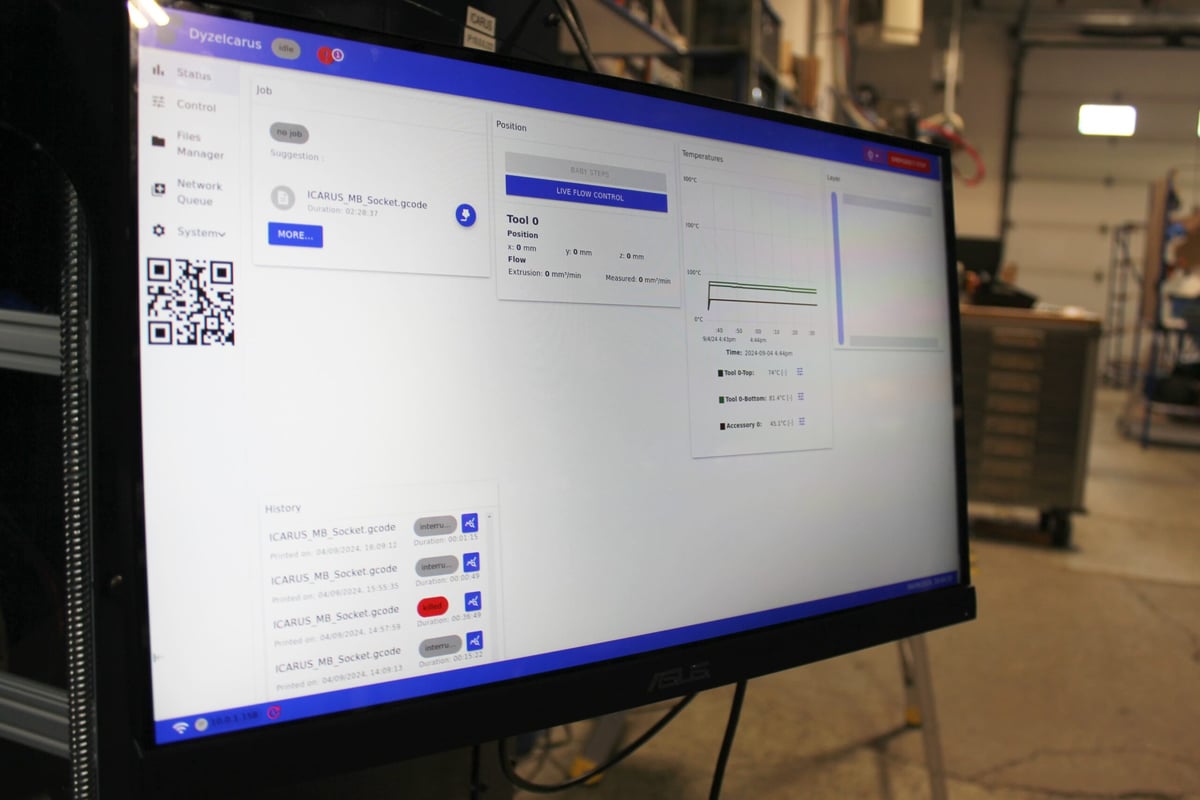

The Aurora can be used with any HDMI-compatible screen, and an advanced maintenance panel enhances usability with real-time monitoring, usage tracking, and notifications for preventive maintenance. A “manufacturer dashboard” further streamlines operations, providing cloud-based troubleshooting and customizable branding options.

Powerful, Versatile, and Built for Precision

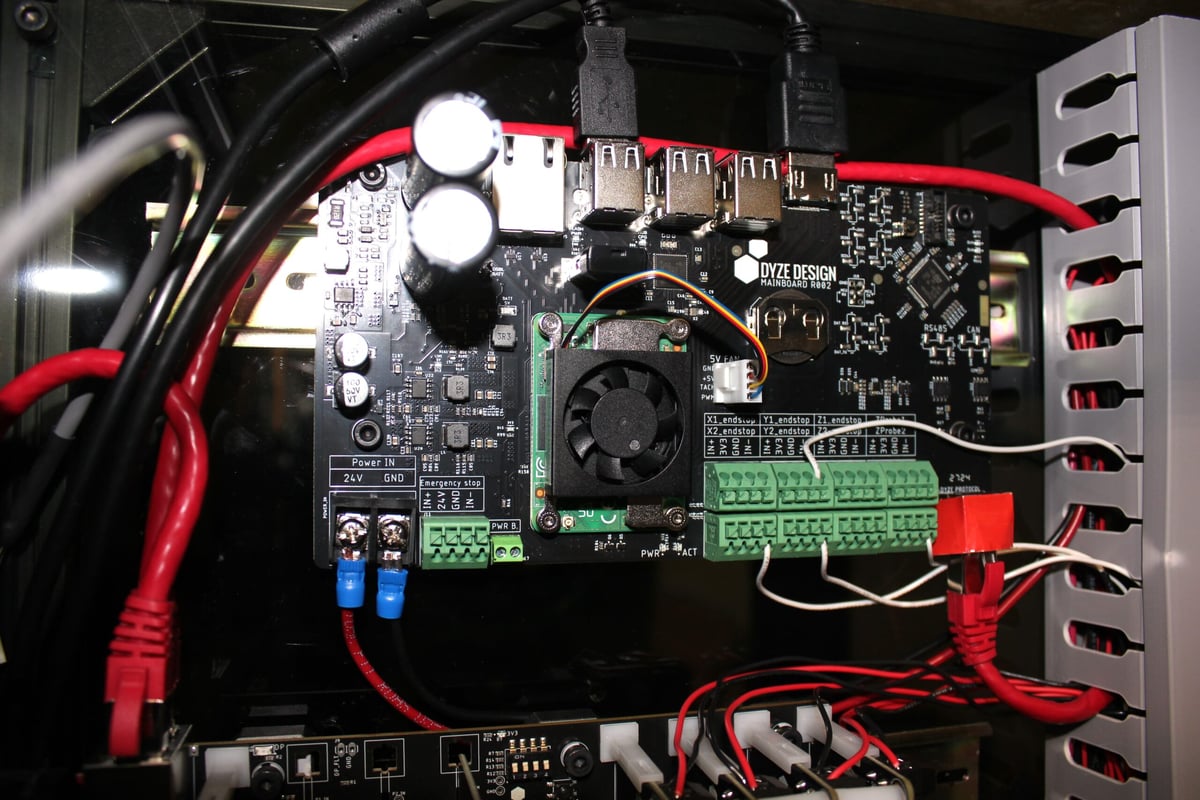

On the hardware front, the Aurora features a 32-bit STM microcontroller unit (MCU) and a 64-bit quad-core ARM Cortex-A72 processor, helping it perform efficiently and multitask with ease.

A host of connectivity options work to up the device’s versatility, with six USB ports, HDMI, RJ45 Ethernet, and built-in Wi-Fi. There’s also support for a wide range of industrial sensors, including capacitive, inductive, and laser types. The Aurora runs on Dyze Design’s custom-built firmware and Operating System, as well as their own communication protocol, which is optimized for 3D printing applications.

Join the Early-Access Program

Dyze Design invites users to experience the Aurora through its Early-Access Program. Participants will receive priority feature integration and customized solutions, so they can be at the forefront of innovations in the 3D printing space. To learn more or join the program, visit dyzedesign.com/aurora-motion-controller.

About Dyze Design

Founded in 2015 and headquartered in Montreal, Quebec, Canada, Dyze Design is dedicated to empowering individuals and industries to create the tools and products they need, precisely when and where they need them. Specializing in high-quality and high flow extrusion systems, both for Fused Filament Fabrication (FFF) and Fused Granulate Fabrication (FGF), advanced sensors, accessories, and innovative control systems and software, Dyze Design is recognized for its commitment to high reliability and exceptional performance.

Serving primarily industrial clients with specialized applications, Dyze Design stands out for its advanced solutions that enhance the quality and precision of 3D printed parts. With a focus on pushing the boundaries of what’s possible in 3D printing, Dyze Design continues to lead the way in advanced manufacturing technologies.

For more information, visit dyzedesign.com.

License: The text of "Dyze Design’s New Aurora Motion I/O Controller is a Game-Changer for Professional 3D Printing (Ad)" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.