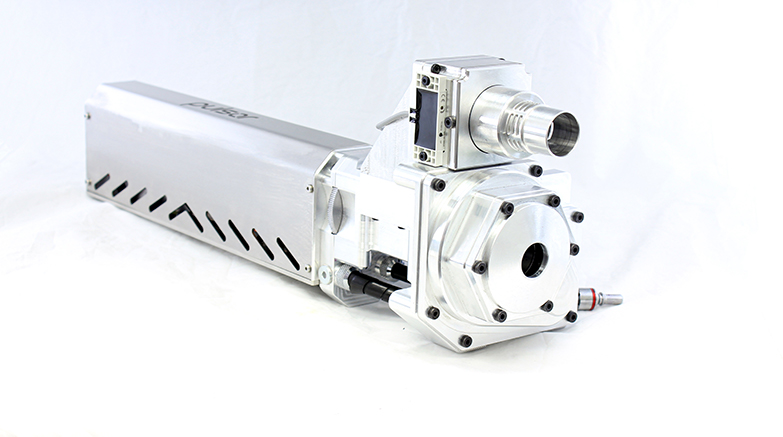

Dyze Design, the Canadian manufacturer of extruders, components, and accessories for 3D printers, is now officially taking preorders for its new printer extruder, Pulsar.

The state-of-the-art, high-flow-rate plastic pellet extruder Pulsar was designed with a single purpose: quickly and cost-effectively 3D print parts of 1 square meter and more. Pulsar is able to output 2.5 kg of material per hour (500 mm³/s).

“Pellet-based extrusion is a true game changer in the 3D printing industry. It enables really high throughput, but most importantly, it reduces your material costs by up to 10 times and gives you access to new kinds of polymers, some that don’t even exist in filament format,” says Simon Duchaine, chief marketing officer of Dyze Design. “There’s more and more demand for pellet-based printers or extrusion systems in the industry. Companies just want to get things done faster, at a lower cost. Pellets give you the best of both worlds.”

The Pulsar extruder is intended to work with pellets, also commonly known as granules, ranging in size from 3 mm to 5 mm. Pellets can be from popular polymers to more advanced engineering material, such as PEEK, PEAK, PEI, PVA, and HIPS due to its maximum operating temperature of 500 °C and its integrated liquid-cooling loop.

Optimized for Industrial 3D Printing

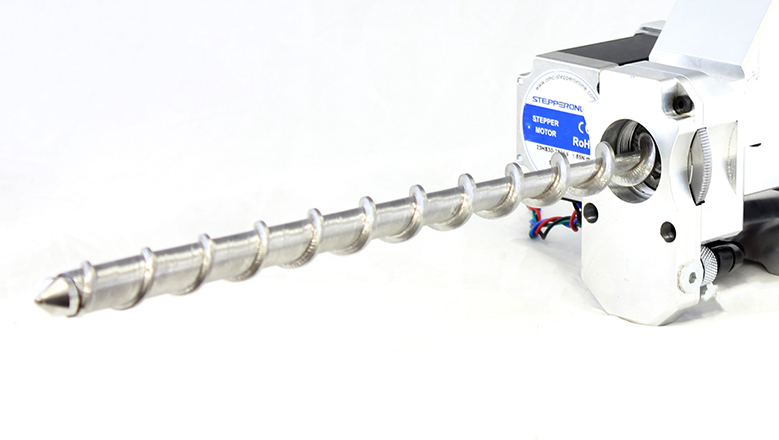

The customized screw design is optimized for 3D printing with high resolution. The triple heat zone guarantees the polymer is at a constant temperature: the top section receives cold pellets and generates more heat to melt them. Then, the middle zone stabilizes the polymer at a precise temperature. Lastly, the nozzle heater ensures an even flow. The Pulsar also features an “anti-oozing mechanism.” As the screw can’t pull molten plastic, an anti-oozing device ensures nice looking prints without any flaws, such as “hairs” appearing during linear travels.

With dimensions of 48 x 17 x 13 cm, Pulsar is designed for rather large printers with a printing volume of 1 cubic meter and more. “Pulsar lets you print large parts, like a chair or even a car, in a single piece,” says Duchaine. “The extruder could actually be installed on a robotic arm, which is a trend we’re starting to see. Industry already has access to robotics arms on premises, so they simply mount an extrusion tool head to enable FDM technology.”

The extruder is also compatible with any standard open source firmware (Marlin, RepRap, Repetier, etc.)

Regarding supplying granules to the extruder, a hopper can be fixed on the extruder input to make use of gravity or an automatic feeding system can be purchased as an add-on to continuously bring pellets from a bulk container.

Last year, Dyze Design conducted rigorous testing of the extruder through a beta program. Several industrial or large-scale 3D printer manufacturers experimented and provided feedback, such as Compound Dynamics, Filament Innovations, Tobeca, Hybster, Rapid 3D, and Lynxter.

The Pulsar extruder is now officially open for preorders. It is priced at $7,949. Preorders will be fulfilled in Q1 2021.

About Dyze Design

Montréal-based company Dyze Design has been in the 3D printing industry since 2015 developing and manufacturing cutting-edge high performance, reliable, and innovative extrusion systems and 3D printer components for professional and industrial 3d printers. They are renowned for their Typhoon™ high-flow extruder, DyzeXtruder GT and DyzeXtruder Pro extruder line, their SENTINEL™ filament detector or Tungsten Carbide Nozzles. Today, many 3D printer brands such as Roboze, Sharebot, Blackbelt, Dynamical 3D, AON3D, Trideo, 3DPlatform, Filament Innovations, Mark One, and Cincinnati Inc. have chosen their hotends, extruders, and nozzles as OEM parts for their industrial or high-end printers.

License: The text of "Dyze Design’s Pulsar Pellet Extruder" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.